Automatic silicon crystal plate counting and integer packaging device

An automatic counting, silicon wafer technology, applied in packaging, packaging machines, packaging protection and other directions, can solve the problems of wasting manpower, material resources, time and economic costs, save manpower, material resources, time, simple actions, and unique self-diagnosis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

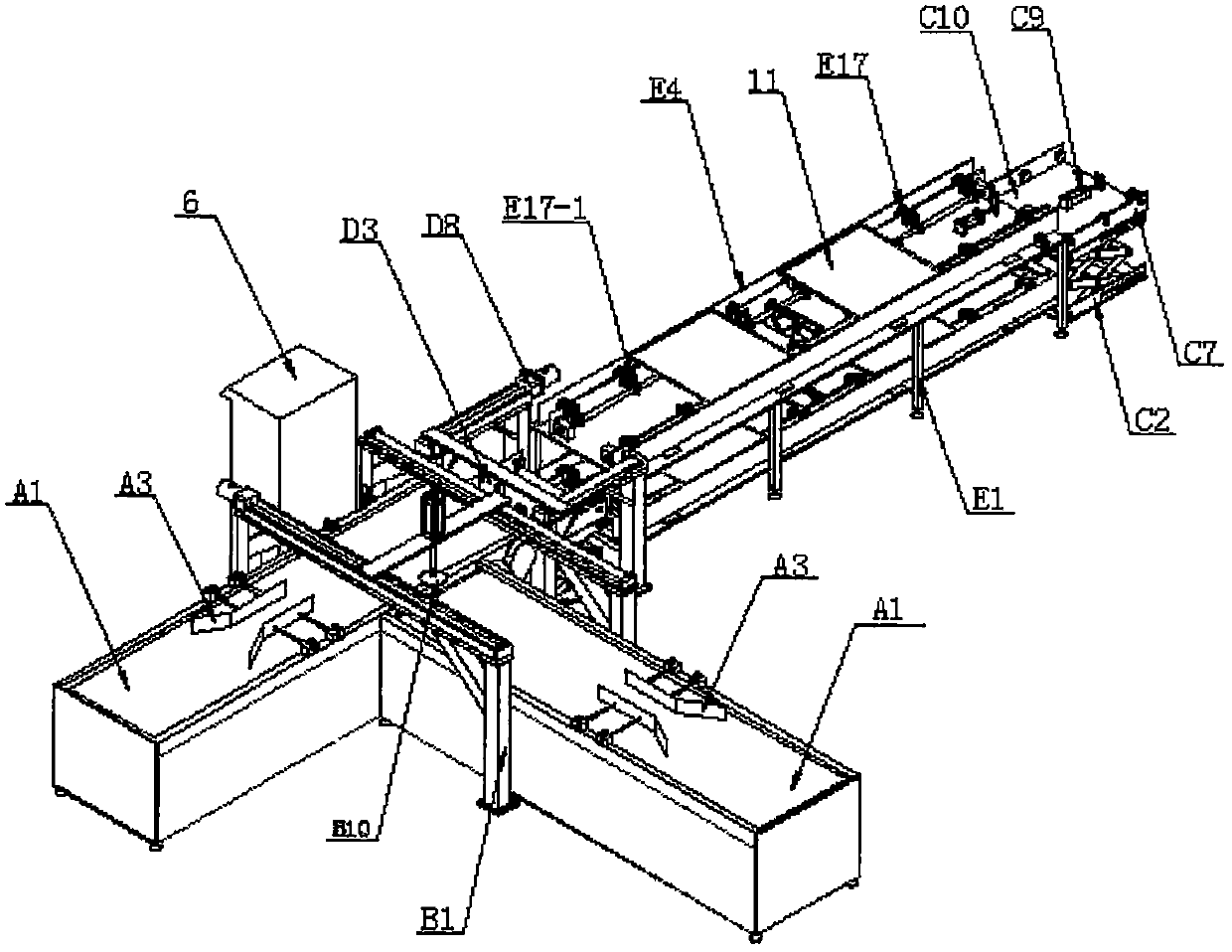

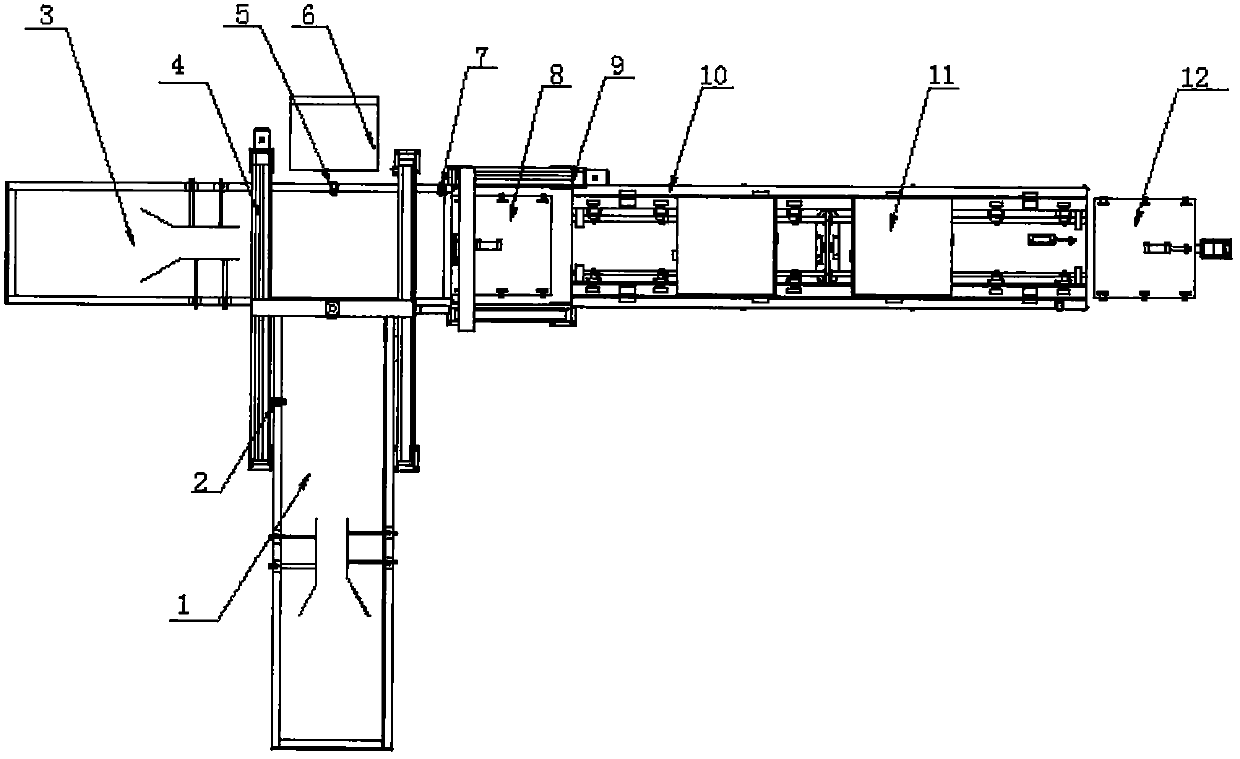

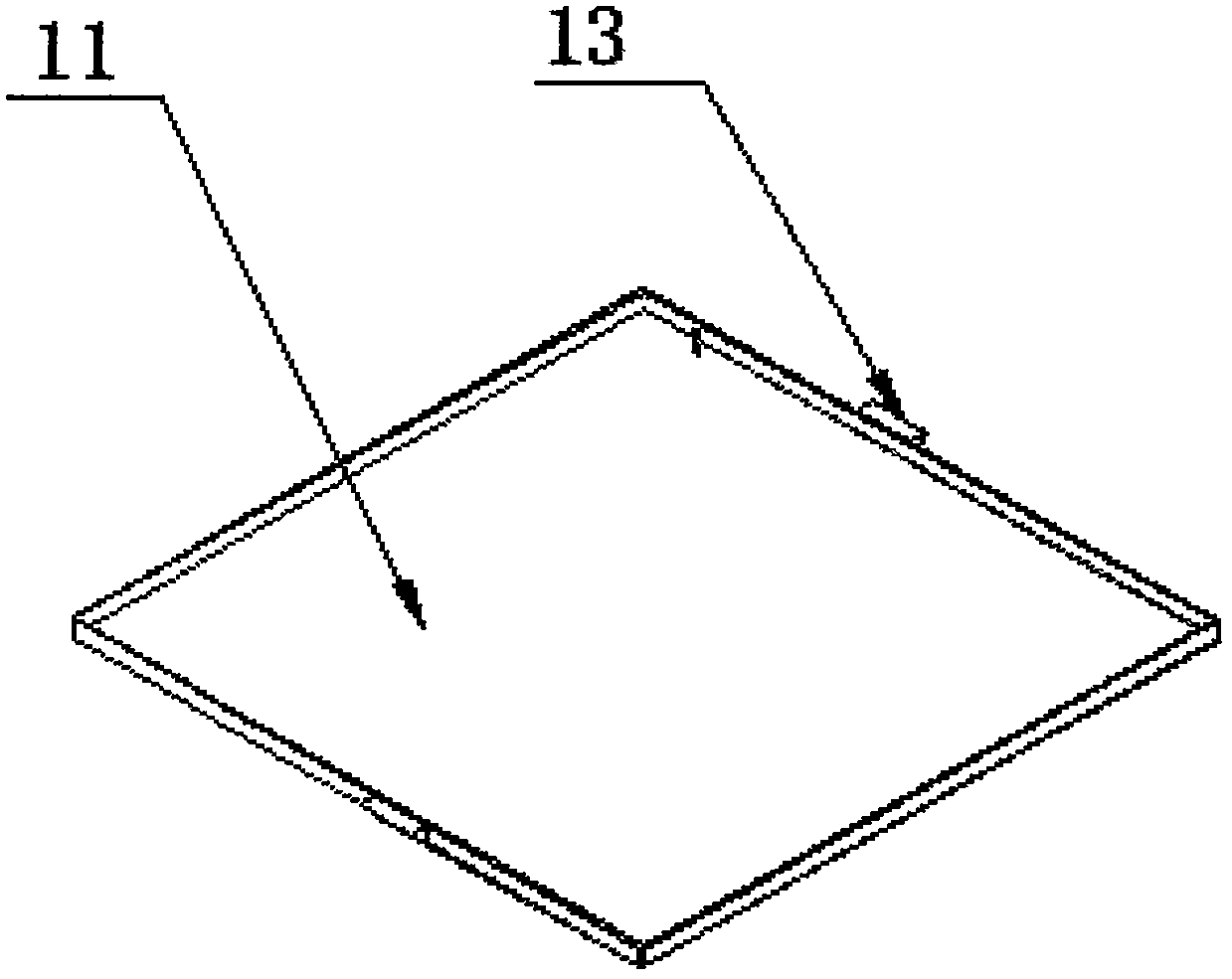

[0032] Refer to the accompanying drawing for an automatic counting integer packaging device for silicon crystal plates, including a first conveyor 1, a conveyor belt A1, a main beam A2, a guide plate A3, a torx screw A4, a fixed block A5, a fixed shaft A6, and a motor cover A7, foot cup A8, side plate A9, frame A10, reduction motor A11, transmission chain A12, drive roller A13, pressure roller A14, supporting plate A15, idler roller A16, driven roller A17, first photoelectric sensor switch 2, Second conveyor 3, suction cup moving device 4, first gantry B1, first servo motor B2, first chute B3, first screw rod B4, second gantry B5, vacuum cylinder B6, first dovetail guide rail B7, vacuum cylinder fixing plate B8, first dovetail slider B9, vacuum suction cup B10, first piston rod B11, ball slider B12, second photoelectric sensor switch 5, distribution box 6, infrared sensor counter 7, first Elevator 8, first scissors part 1C1, lift lower fixing plate C2, first scissors part 2C3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com