Injection molding mold provided with conveying device

A conveying device and injection mold technology, applied in the field of injection molds, can solve problems such as inconvenient conveying, high conveying cost, and inconvenient use, and achieve the effects of reducing complex structures, high working performance, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

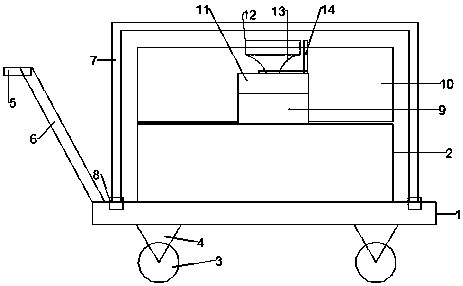

[0013] See figure 1 The present invention provides a technical solution: an injection mold equipped with a conveying device, comprising a conveying device 1 and a molding device 2, the molding device 2 is installed inside the conveying device 1, and the bottom of the conveying device 1 is provided There are wheels 3, the wheels 3 are mounted on the bottom surface of the conveying device 1 through a tripod mount 4, wherein the number of wheels 3 and the tripod mount 4 are both four, and a push handle 5 is provided at one end of the conveying device 1. The push handle 5 is installed at one end of the conveying device 1 through a push rod 6. The push handle 5 and the push rod 6 are connected by welding. The top of the conveying device 1 is provided with a protective cover 7, wherein the protective cover 7 and the push rod 6 are adopted Made of cemented carbide, the protective cover 7 is connected to the bottom of the conveying device 1 through a mounting slot 8. The molding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com