A device for punching holes in spherical glass products

A technology for glass products and punching devices, which is applied in the direction of manufacturing tools, work accessories, stone processing tools, etc., can solve the problems of increased difficulty, long processing time, unreliability, etc. The effect of enhancing the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

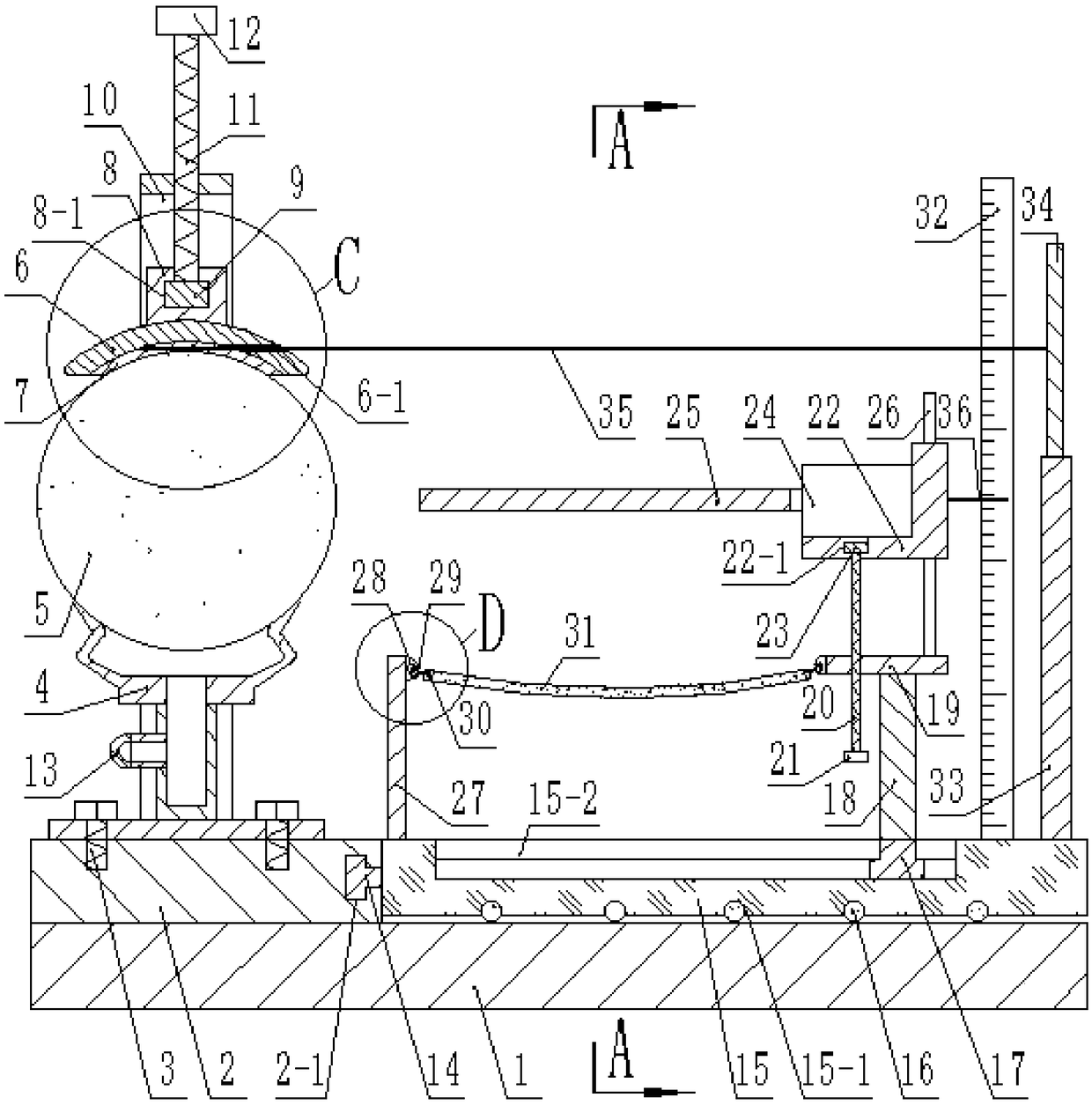

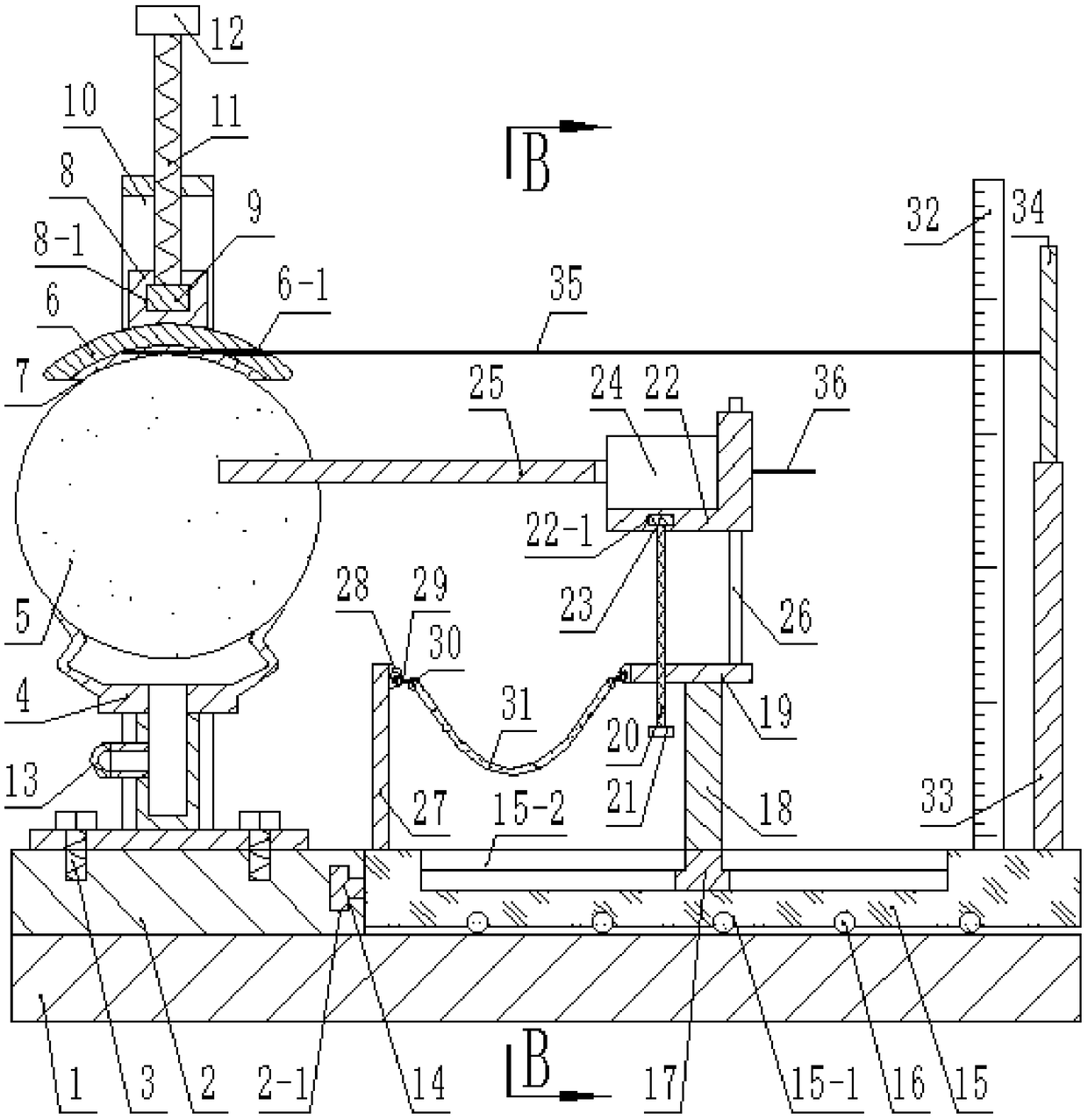

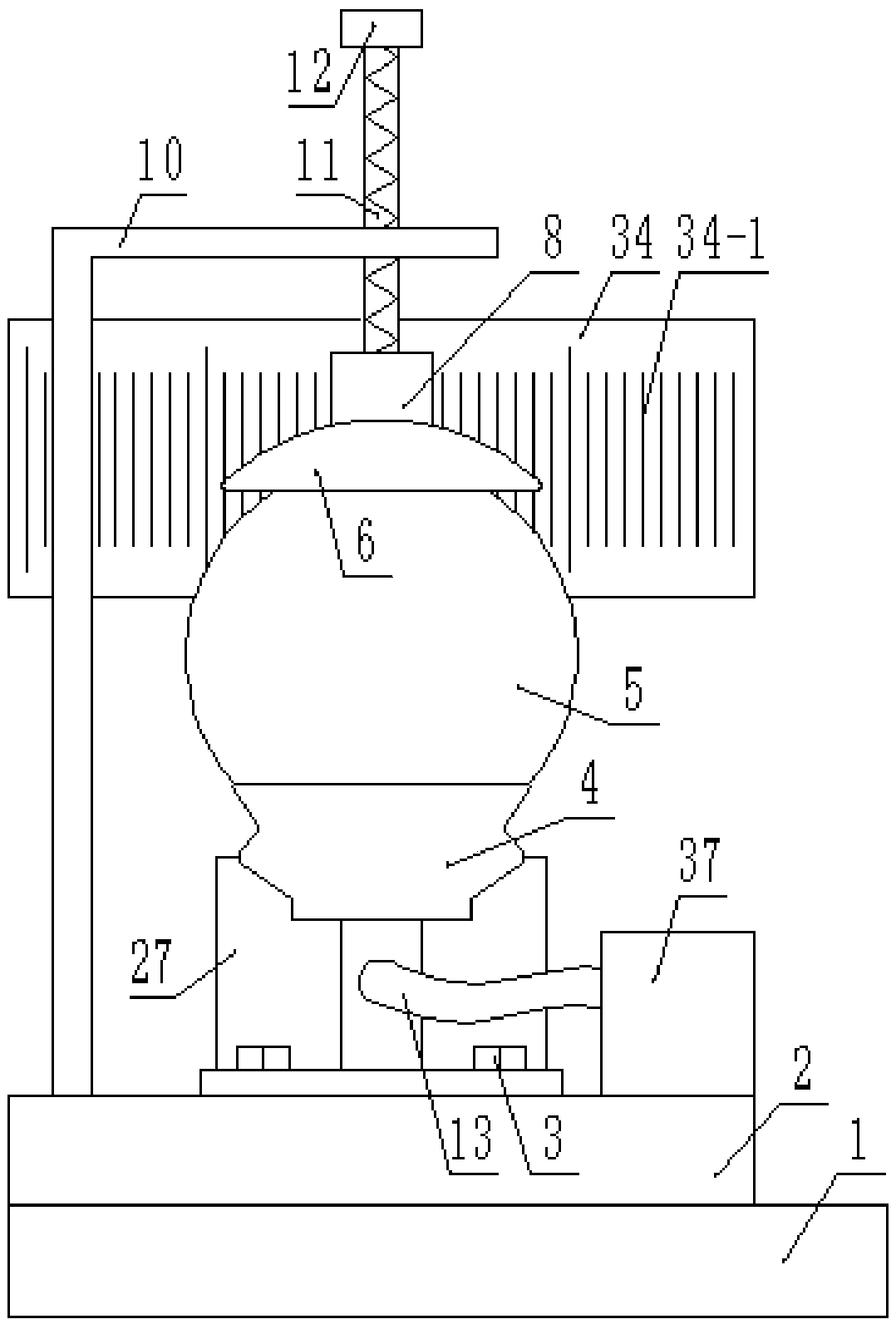

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] Such as Figure 1-Figure 8 As shown, a spherical glass product punching device includes a bottom plate 1, the top surface of the bottom plate 1 is fixed with a fixed plate A2, and the top surface of the fixed plate A2 is fixed with a vacuum suction cup 4 by bolts 3, and the vacuum suction cup 4 is provided with a spherical glass product 5, the top surface of the spherical glass product 5 is provided with an arc-shaped clamp block 6, the inner arc surface of the arc-shaped clamp block 6 is attached with a rubber layer 7, and the arc-shaped clamp block The side of the block 6 is provided with a through hole A6-1, and the inside of the rubber layer 7 is embedded with a pointer A35. Pass through, the top surface of the arc-shaped clamping block 6 is fixed with a fixed block A8, the top surface of the fixed block A8 is provided with a blind h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com