Non-eccentricity type through hole double-face chamfering tool and chamfering process using chamfering tool

A chamfering tool, non-eccentric technology, used in milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problems of low work efficiency, imperfect functions, poor processing stability and safety, etc., to achieve simple structure and improve processing. Efficiency, overcoming the effect of low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

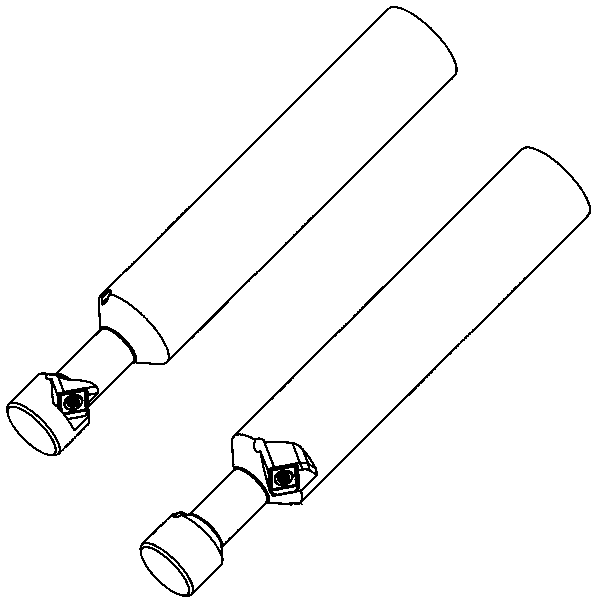

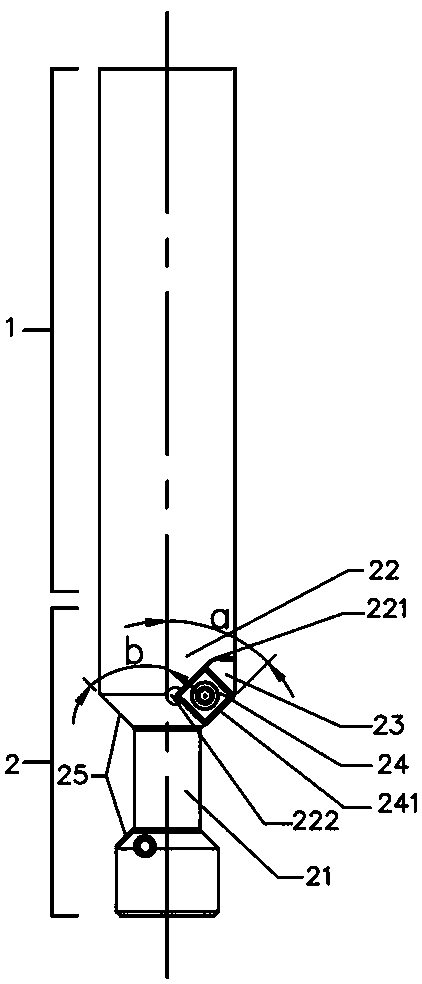

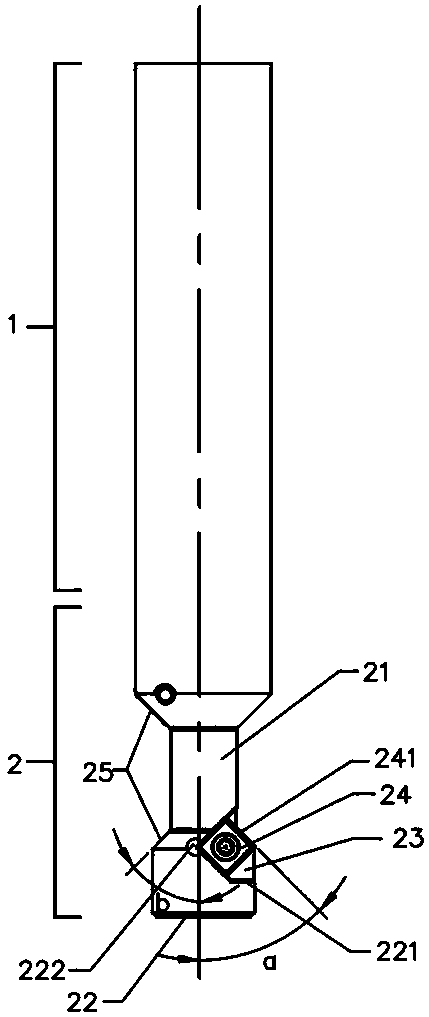

[0031] See figure 1 , figure 2 , image 3 , a non-eccentric through-hole double-sided chamfering tool, including an integrally formed clamping part 1 and a processing part 2, the central axis of the clamping part 1 and the central axis of the processing part 2 are on the same straight line, that is, the non-eccentric of.

[0032] The processing part 2 includes an upper chamfering portion, a lower chamfering portion and a chamfering anti-interference portion 21 between the upper chamfering portion and the lower chamfering portion, the chamfering anti-interference portion 21, the upper chamfering portion, and the lower chamfering portion The central axes of the three are on the same straight line, and the cross-sectional diameters of the chamfering anti-interference portion 21 are smaller than the diameters of the upper chamfering portion and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com