Stirring device for slurry mixing tank

A stirring device and slurry mixing tank technology, which is applied in the field of water-based paint production equipment, can solve the problems that materials are easy to adhere to the inner wall and bottom of the tank, and achieve the effects of thorough scraping, convenient disassembly and replacement, and avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

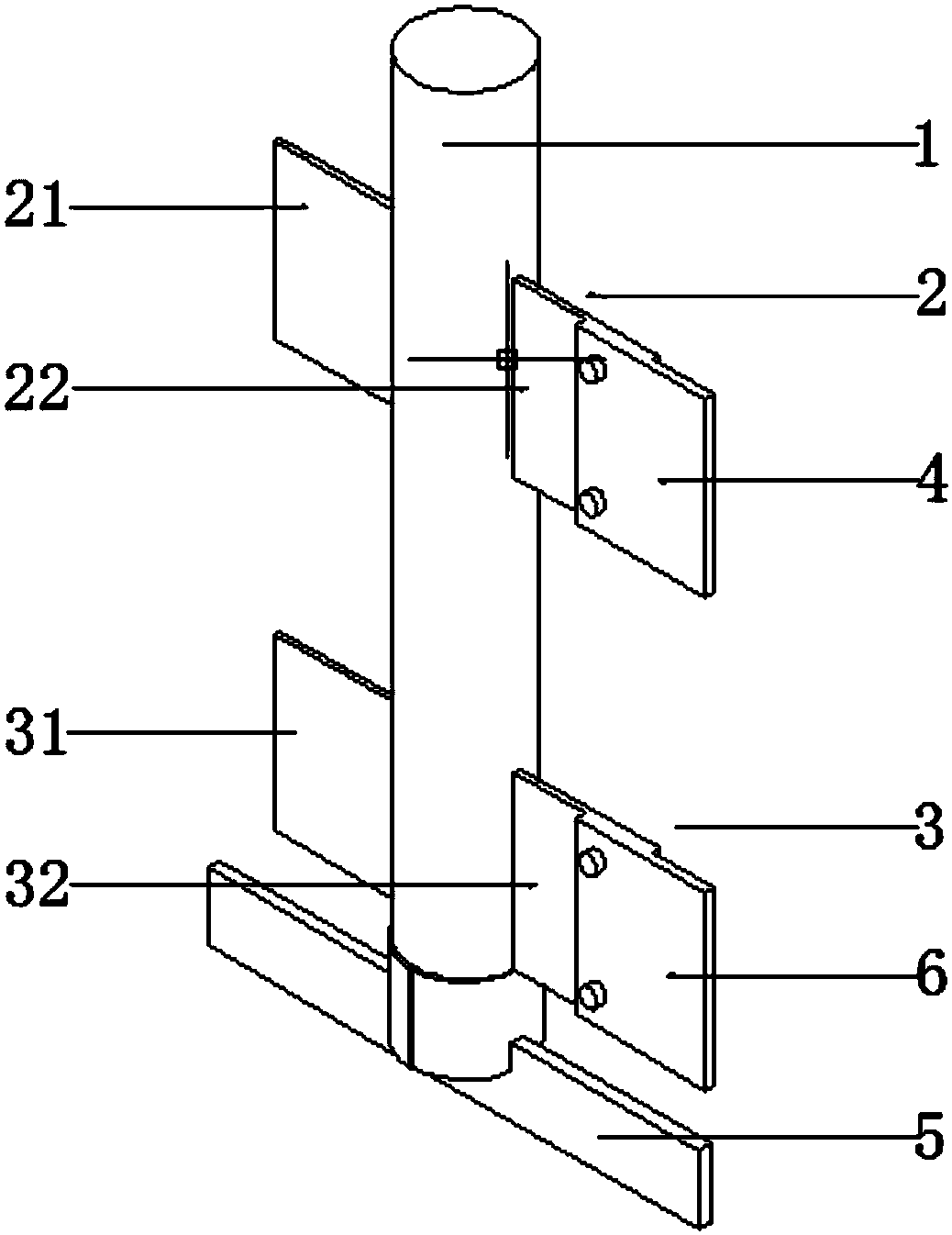

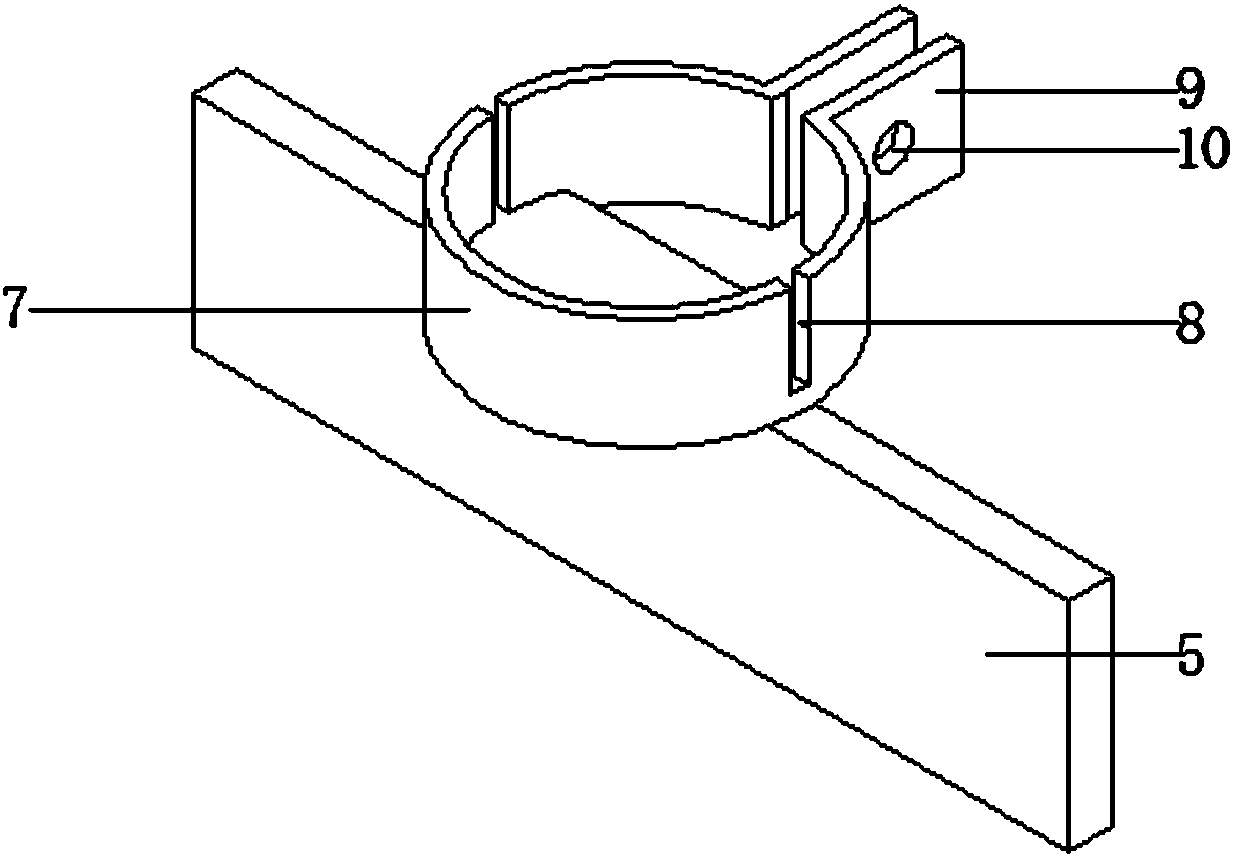

[0019] Such as figure 1 and figure 2 As shown, a stirring device for a slurry mixing tank includes a stirring shaft 1, which is provided with a first stirring paddle 2 and a second stirring paddle 3, and the first stirring paddle 2 is located on the side of the stirring shaft 1 The upper part, the second stirring paddle 3 is located at the lower part of the stirring shaft 1, the first stirring paddle 2 includes a first left paddle 21 and a first right paddle 22, the first right paddle 22 is provided with a positioning hole, the first The right paddle 22 is detachably connected to the first brush plate 4 through positioning holes and bolts. The end of the first brush plate 4 is provided with bristles, and the lower end of the stirring shaft 1 is provided with a second brush plate 5. The second brush plate 5 The ends are provided with bristle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com