A magnetic bearing device applied to a shaftless propeller of a ship

A thruster and magnetic bearing technology, applied in the field of magnetic bearings, can solve problems such as complex control process, and achieve the effects of simplified excitation current control, simple control and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

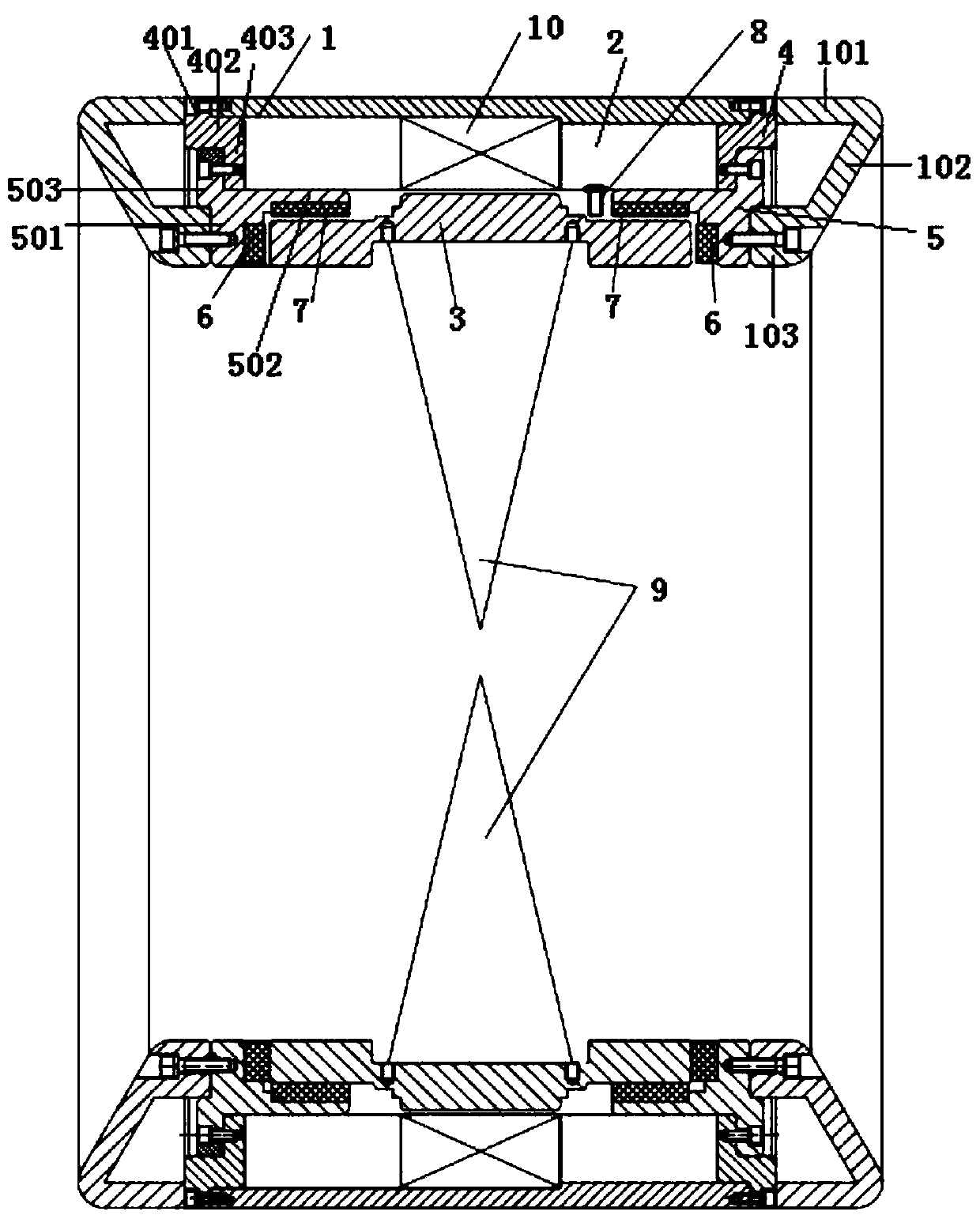

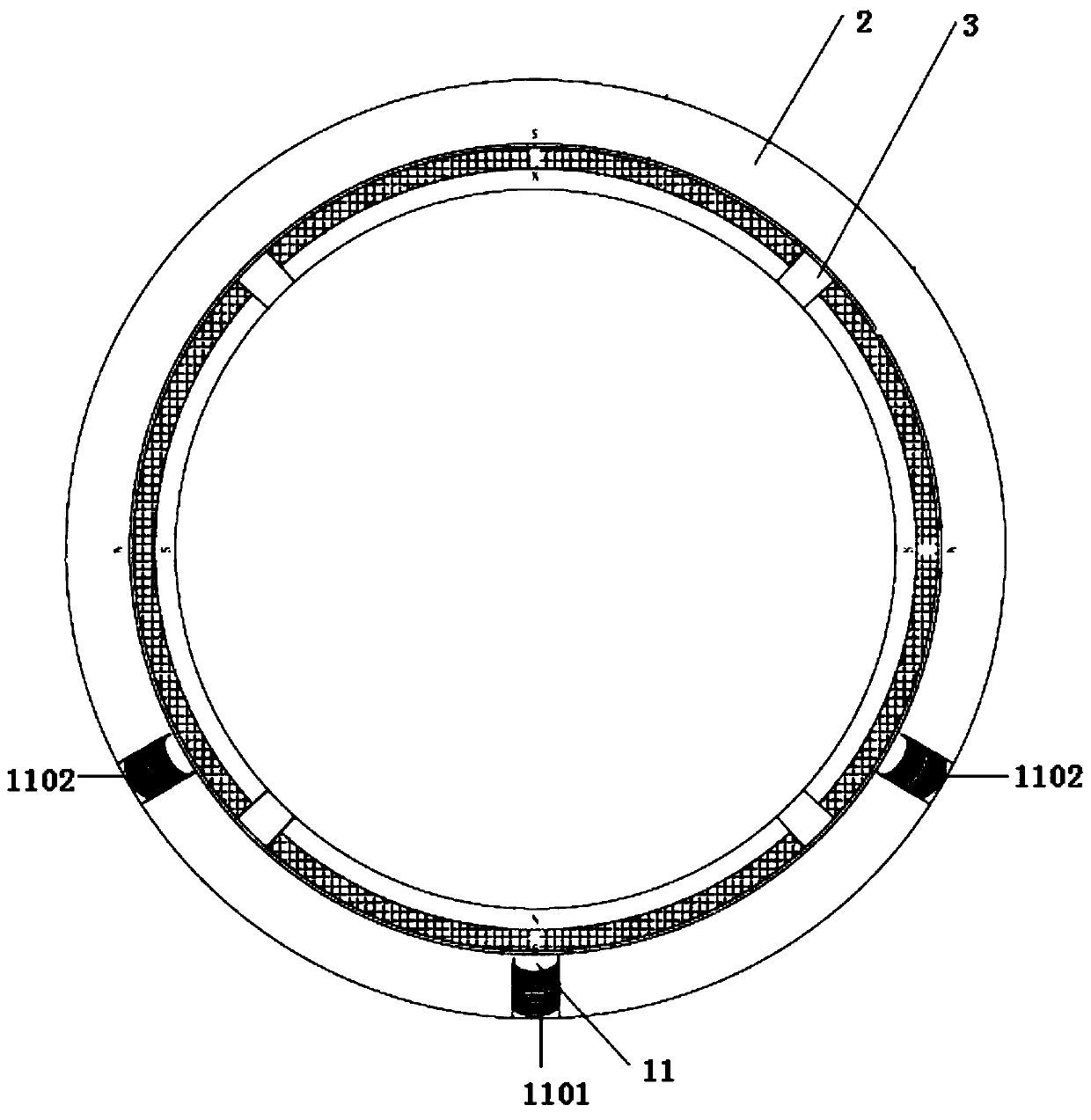

[0021] A magnetic bearing device applied to a shaftless propeller of a ship, such as figure 1 and figure 2 As shown, it includes a propeller housing 1, a stator 2 and a rotor 3. The propeller housing 1 is a cylindrical structure, and two first clamping blocks 4 are fixed at both ends of the inner surface of the side wall of the propeller housing 1. One end of a first clamping block 4 is fixed with two second clamping blocks 5, and the two second clamping blocks 5 are fixed at both ends of the propeller housing 1;

[0022] Both ends of the stator 2 are clamped between the two first clamping blocks 4, and the inner surface of the side wall of the stator 2 is in contact with the top surfaces of the two second clamping blocks 5; the side wall of the stator 2 A Hall sensor 8 is fixed on the inner surface, a torque coil 10 is embedded in the middle of the stator 2, and three sets of excitation windings 11 are wound and fixed on the side wall of the stator 2. The excitation winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com