Metal encapsulating structure and preparation method thereof, encapsulating method of display panel and display device

A technology for metal packaging and display panels, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as poor peeling, waste of adhesive film and metal film, and equipment shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

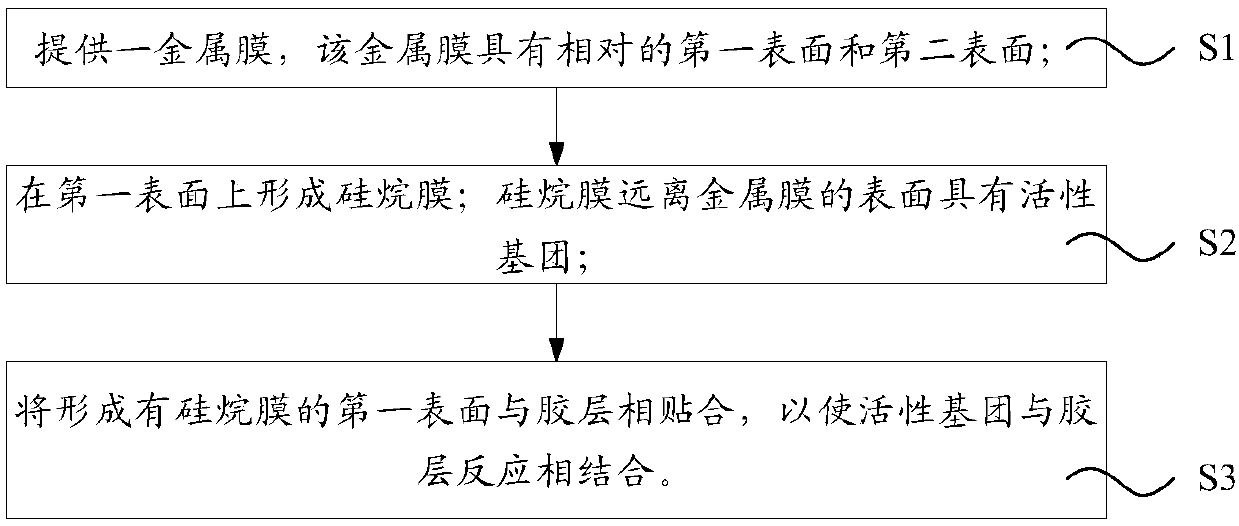

[0046] Such as figure 1 As shown, Embodiment 1 of the present invention provides a manufacturing method of a metal packaging structure, and the manufacturing method includes:

[0047] Step S1: providing a metal film, the metal film having a first surface and a second surface opposite to each other;

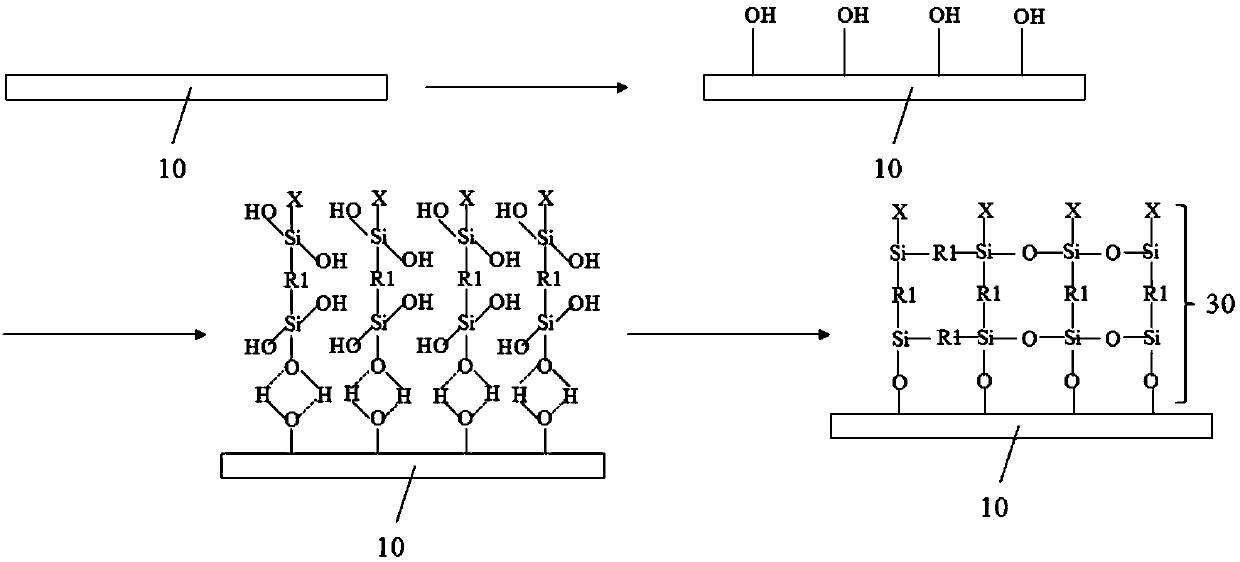

[0048] Step S2, forming a silane film on the first surface; the surface of the silane film away from the metal film has active groups;

[0049] Step S3, bonding the first surface on which the silane film is formed with the adhesive layer, so that the active groups and the adhesive layer are combined by reaction.

[0050] It should be noted that the specific materials of the above-mentioned metal film and the adhesive layer can use the conventional materials of the metal packaging process in the prior art.

[0051] Among them, since the above-mentioned metal packaging structure is specifically used for surface packaging display substrates, considering that the base substrate of the display s...

Embodiment 2

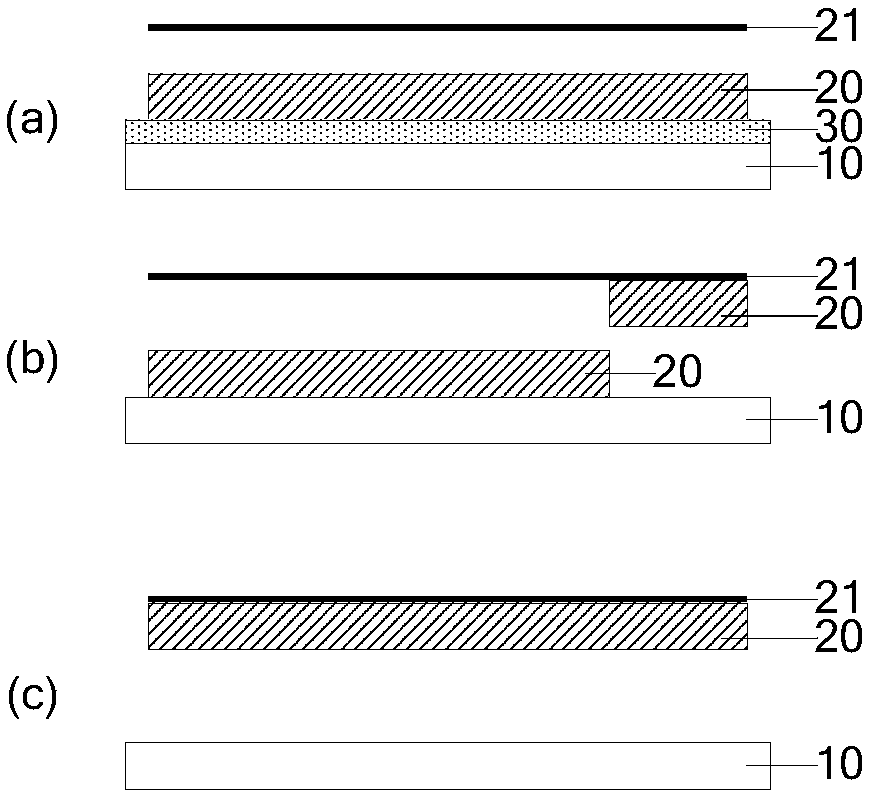

[0091] Embodiment 2 of the present invention provides a metal package structure formed by the preparation method of the above embodiment 1. The metal package structure includes: a metal film having a first surface and a second surface opposite to each other; The silane film on the surface, the surface of the silane film away from the metal film has active groups (refer to Figure 4 Shown); a glue layer attached to the first surface to which the silane film is attached, the glue layer can react and combine with the above-mentioned active groups to form a covalent bond.

[0092] In this way, the silane film provided on the first surface of the metal film is covalently bonded to the surface of the metal film, so that the silane film can be more firmly attached to the first surface of the metal film. The surface of the silane film away from the metal film is designed to have active groups, and the active groups react with a large number of reactive groups in the dormant state to form ...

Embodiment 3

[0097] Embodiment 3 of the present invention provides a packaging method of a display panel. The packaging method includes: providing the metal packaging structure of any one of the foregoing embodiments 2; and attaching the adhesive layer of the metal packaging structure to the display panel on the side of the adhesive layer away from the metal film. On the panel.

[0098] The above packaging method specifically includes: peeling off the protective film attached to the side of the adhesive layer away from the metal film in the metal packaging structure to expose the side of the adhesive layer away from the metal film; attaching the side of the adhesive layer away from the metal film to the display panel .

[0099] Such as Image 6 As shown, the specific packaging process is: peeling off the protective film 21 under the adhesive layer 20, and attaching it to the first surface of the metal film 10 on which a silane film (not shown in the figure) is formed by a hot pressing process; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com