Method and apparatus to regulate oil pressure via controllable piston cooling jets

A piston cooling nozzle, oil pressure technology, used in the control of lubricant pressure, engine cooling, pump control, etc., can solve problems such as affecting flow rate, increasing component damage, and expensive variable flow oil pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

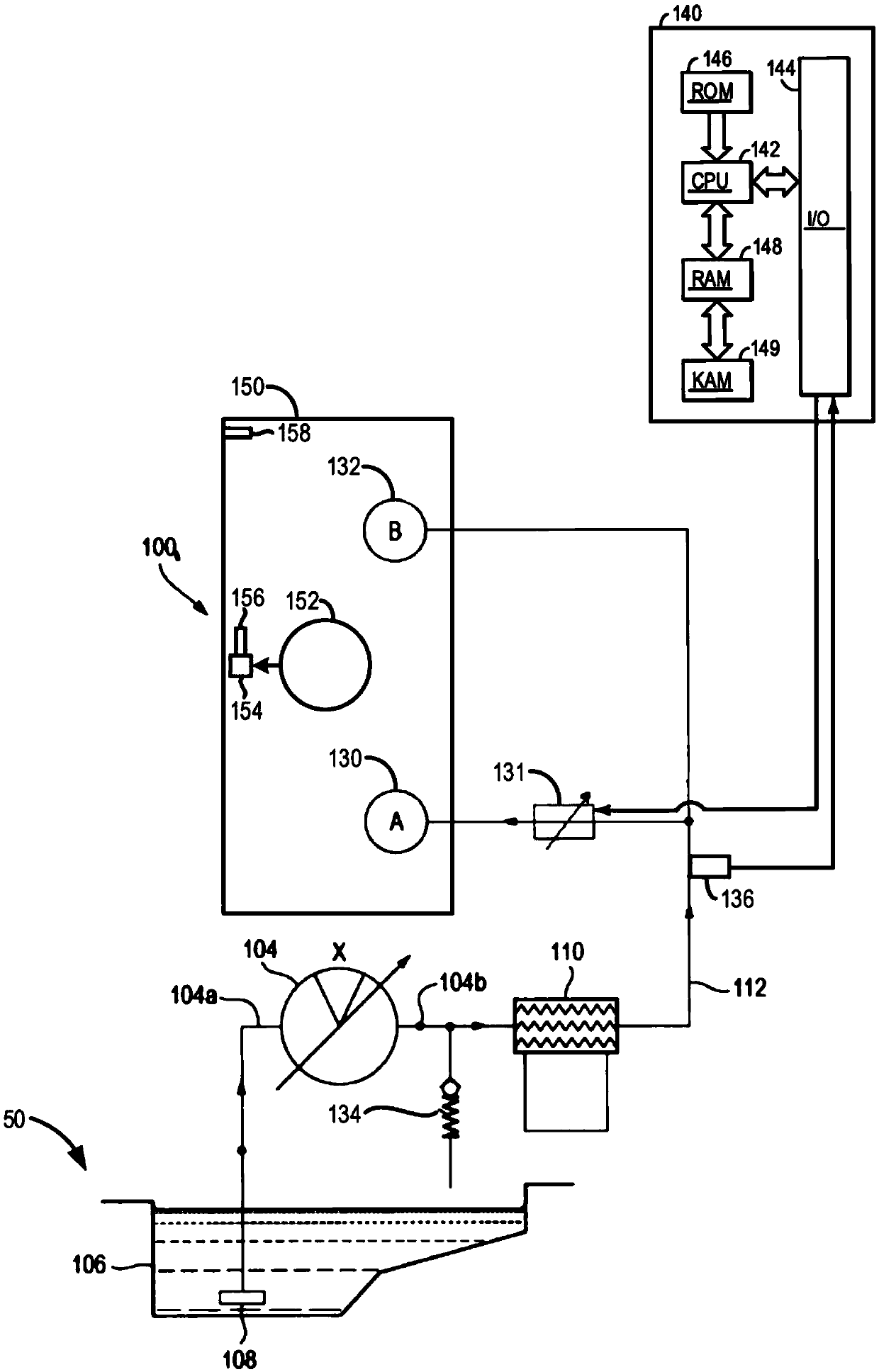

[0015] Referring to prior art FIG. 1 , a previously proposed engine assembly 1 for a motor vehicle includes an oil system 2 , a crankshaft 14 and a plurality of pistons 16 configured to reciprocate within a plurality of cylinders 18 . The engine assembly 1 further includes a valve train 20 including a plurality of intake valves 22 and exhaust valves 24 and a camshaft 26 .

[0016] Intake valve 22 and exhaust valve 24 are configured to control the flow of intake air and exhaust gas into and out of cylinder 18 , respectively. Camshaft 26 is configured to control operation of intake valve 22 and exhaust valve 24 .

[0017] The oil system 2 comprises an oil pump 4 configured to suck oil from an oil sump 6 to an inlet 4a of the oil pump via an oil pick-up 8 . The oil pump can be driven by the engine. For example, as shown in FIG. 1 , the oil pump 4 may be driven by the crankshaft 14 via the drive belt 5 . The oil pick-up 8 may include a pick-up filter 8a configured to reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com