Large-deformation preliminary bracing system for high-ground-stress soft rock

A technology of initial support and high in-situ stress, applied in underground chambers, wellbore linings, tunnel linings, etc., can solve the problems of cavity-induced landslides, cracking, structural instability, etc., to improve distortion, reduce loads, and improve integrity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in combination with specific embodiments.

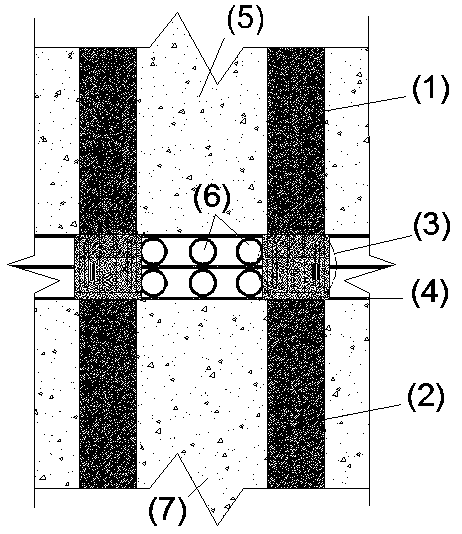

[0034] The present invention relates to a large-deformation initial support system for soft rock with high ground stress, which includes multi-ring H-shaped steel arches arranged in parallel in the longitudinal direction, and longitudinally connected steel bars or channel steels are used between two vertical steel arches. The single steel arch frame is divided into multiple sections in the circumferential direction, and the nodes are connected by socket-type steel arch joints 3 . The single steel arch frame is divided into six sections in the circumferential direction, and the nodes are respectively located at the vault, the spandrels on both sides and the steps on the waists of the arches on both sides.

[0035] The socket-type steel arch joint 3 includes a U-shaped base and two convex columns symmetrically arranged in the U-shaped base, and the gap between the two conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com