Method for setting up drainage blind ditches in large-scale landfill site in loess hilly and gully region

A technology for drainage of blind ditches and gully areas, which is applied in construction, infrastructure engineering, etc., and can solve the problems of difficult selection of blind ditches and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

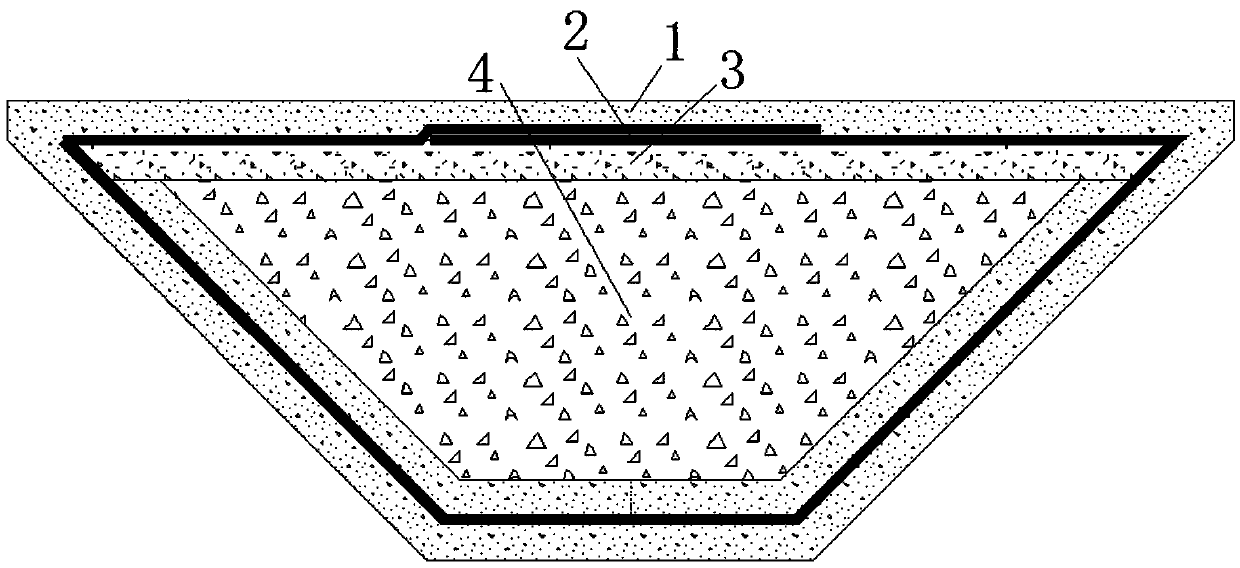

[0021] A method for setting up blind drainage ditches in large-scale filling sites in loess hilly and gully areas is as follows:

[0022] The design of the blind ditch route is based on the principle of not changing or destroying the original flow direction. According to the original topography and natural water system of the site, the primary and secondary blind ditch is set according to the surface catchment area and flow, and the main blind ditch is set in the valley with large catchment area and flow. For ditch, set secondary blind ditch in small gully, set drainage branch blind ditch at spring hole, structural water outlet or other seepage point, said primary, secondary and branch blind ditch are connected to form a complete drainage blind ditch system;

[0023] The stratum position of the blind ditch is selected to be set at the interface between the soil layer and the bedrock, the trench is excavated in the bedrock, and the excavation is cleaned to the moderately weathered be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com