A kind of al-ti-b-sr composite master alloy and its preparation method and application

A technology of al-ti-b-sr and master alloy, which is applied in the field of Al-Ti-B-Sr composite master alloy and its preparation, can solve the problem that the feeding process is not easy to control, etc., and achieve the easy control and utilization of the refined modification process High rate, good effect of refinement and metamorphism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

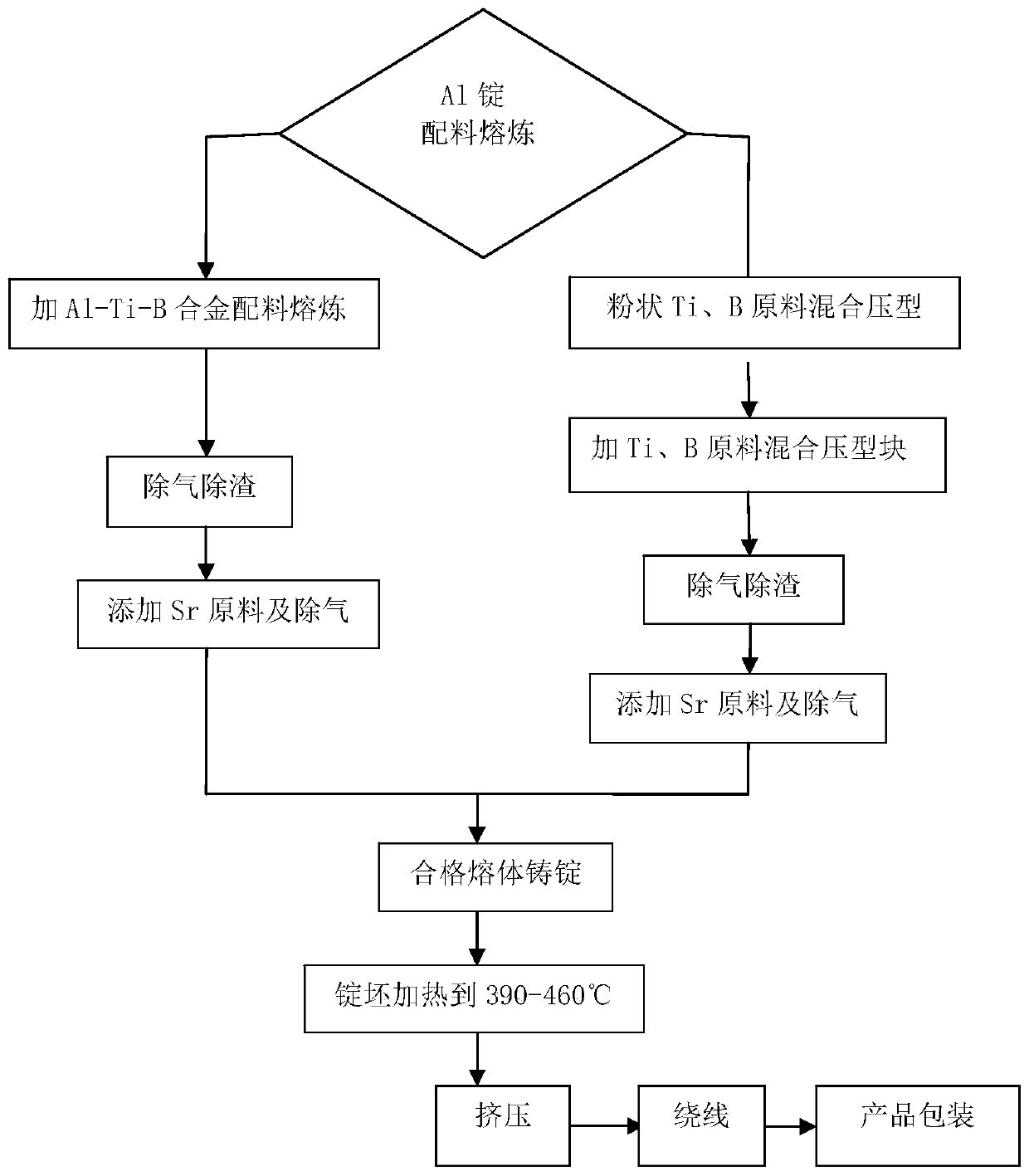

[0039] An embodiment of the Al-Ti-B-Sr composite master alloy of the present invention, the preparation method of the Al-Ti-B-Sr composite master alloy described in this embodiment, the flow chart is as follows figure 1 , including the following steps:

[0040] 1) Ti powder (Ti99.0%, particle size 4 Raw materials (particle size4 1.23kg of raw material, mixed evenly with 0.53kg of Ti powder, pressed into a mass of 160.0g, a thickness of 8-12mm, and a density of 2.4-2.8g / cm 3 round cakes.

[0041] 2) Put a certain amount of industrial pure aluminum (Al99.7%) into the medium-frequency induction heating graphite crucible furnace to melt, put the round cake of 1) into the Al melt according to 17.5% of the mass of the aluminum melt, and quickly heat the melt When the temperature reaches 800°C, the reaction is all over after 3 to 5 minutes, and water slag is discharged from the upper layer of the melt.

[0042] 3) When the temperature of the melt is 800° C., a graphite tube is used...

Embodiment 2

[0055] An embodiment of the Al-Ti-B-Sr composite master alloy of the present invention, the preparation method of the Al-Ti-B-Sr composite master alloy described in this embodiment, the flow chart is as follows figure 1 , including the following steps:

[0056] 1) Ti powder (Ti99.0%, particle size 4 Raw materials (particle size3 round cakes.

[0057] 2) Put quantitative industrial pure aluminum (Al99.7%) into the medium-frequency induction heating graphite crucible furnace for melting, put the round cake of step 1) into the Al melt by 19.5% of the mass of the aluminum melt, and quickly melt the melt Heating to 850°C, after 3 to 5 minutes, the reaction is all over, and water slag is discharged from the upper layer of the melt.

[0058] 3) When the temperature of the melt is 850° C., a graphite tube is inserted into the melt to pass dry nitrogen gas to perform degassing and slag removal. When the temperature of the melt is 800°C, add the Al-10Sr alloy (wrapped with aluminum fo...

Embodiment 3

[0070] An embodiment of the Al-Ti-B-Sr composite master alloy of the present invention, the preparation method of the Al-Ti-B-Sr composite master alloy described in this embodiment, the flow chart is as follows figure 1 , including the following steps:

[0071] 1) Ti powder (Ti99.0%, particle size 4 Raw materials (particle size3 round cakes.

[0072] 2) Put quantitative industrial pure aluminum (Al99.7%) into the medium-frequency induction heating graphite crucible furnace for melting, put the round cake of step 1) into the Al melt by 18.0% of the mass of the aluminum melt, and quickly melt the melt Heating to 830°C, after 3 to 5 minutes, the reaction is all over, and water slag is discharged from the upper layer of the melt.

[0073] 3) When the temperature of the melt is 800°C, a graphite tube is inserted into the melt to pass through the dried nitrogen gas for degassing and slag removal. When the temperature of the melt is 800°C, add the Al-10Sr alloy (wrapped with alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com