Composite biomass particle fuel

A biomass particle and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of shortened combustion duration, reduced product quality, and damage to production equipment and facilities, achieving good economic and social benefits, and gentle release of combustion Hot, burning effect with long duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

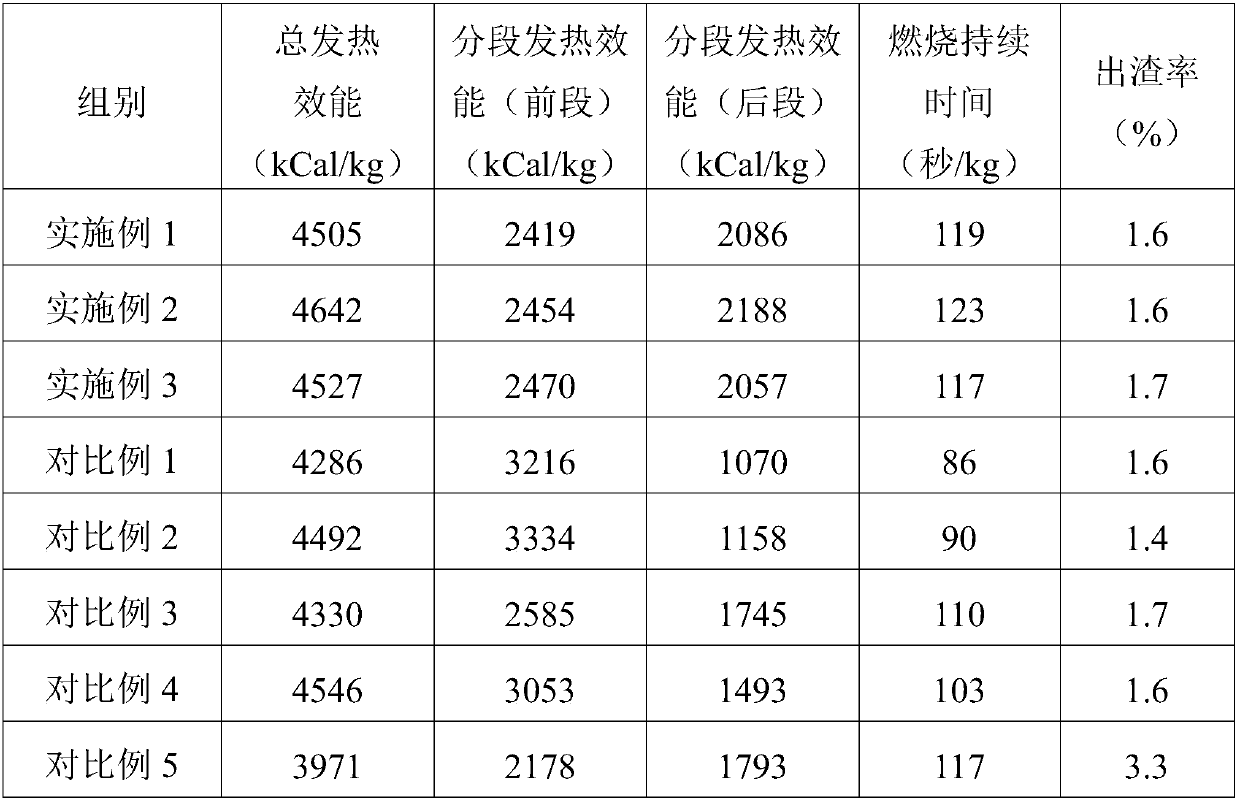

Examples

Embodiment 1

[0045] A composite biomass pellet fuel is made from the following raw materials in mass percentage:

[0046]Fuel matrix 95.6%, graphene 0.6%, coconut shell powder 3.8%;

[0047] Wherein said fuel matrix is made of the raw materials of following parts by weight:

[0048] Wheat straw 30, sawdust 20, corn cob 20, peanut shell 20,

[0049] 20 rice straws, 15 rice husks, 15 camellia husks, 15 cottonseed husks.

[0050] The preparation method is as follows:

[0051] (1) Dry and pulverize wheat straw, sawdust, corncobs, peanut shells, straw, rice husks, camellia husks, and cottonseed husks, respectively, and pass through a 40-mesh sieve, and mix the above-mentioned raw materials evenly in a blender to obtain fuel matrix;

[0052] (2) Graphene, coconut shell powder are joined in above-mentioned fuel matrix, fully stir it and make it mix evenly, add a small amount of water and control the moisture content in the mixed powder that obtains to be 10-12% in stirring process;

[0053...

Embodiment 2

[0055] A composite biomass pellet fuel is made from the following raw materials in mass percentage:

[0056] Fuel matrix 95.8%, graphene 0.7%, coconut shell powder 3.5%;

[0057] Wherein said fuel matrix is made of the raw materials of following parts by weight:

[0058] Wheat straw 35, sawdust 25, corn cob 25, peanut shell 20,

[0059] 20 rice straws, 20 rice husks, 15 camellia husks, 15 cottonseed husks.

[0060] The preparation method is the same as in Example 1.

Embodiment 3

[0062] A composite biomass pellet fuel is made from the following raw materials in mass percentage:

[0063] Fuel matrix 96.0%, graphene 0.8%, coconut shell powder 3.2%;

[0064] Wherein said fuel matrix is made of the raw materials of following parts by weight:

[0065] Wheat straw 40, sawdust 30, corn cob 30, peanut shell 25,

[0066] Straw 25, rice husk 20, camellia husk 20, cottonseed husk 20.

[0067] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com