Pesticide chemical wastewater treatment process

A technology of chemical wastewater and treatment process, which is applied in the direction of special compound water treatment, oxidized water/sewage treatment, multi-stage water treatment, etc. It can solve the problems of complex pollutant composition, high operating cost, and poor treatment effect, and achieve reduction The workload of investment and construction, the effect of reducing labor intensity and land occupation, and simplifying daily management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

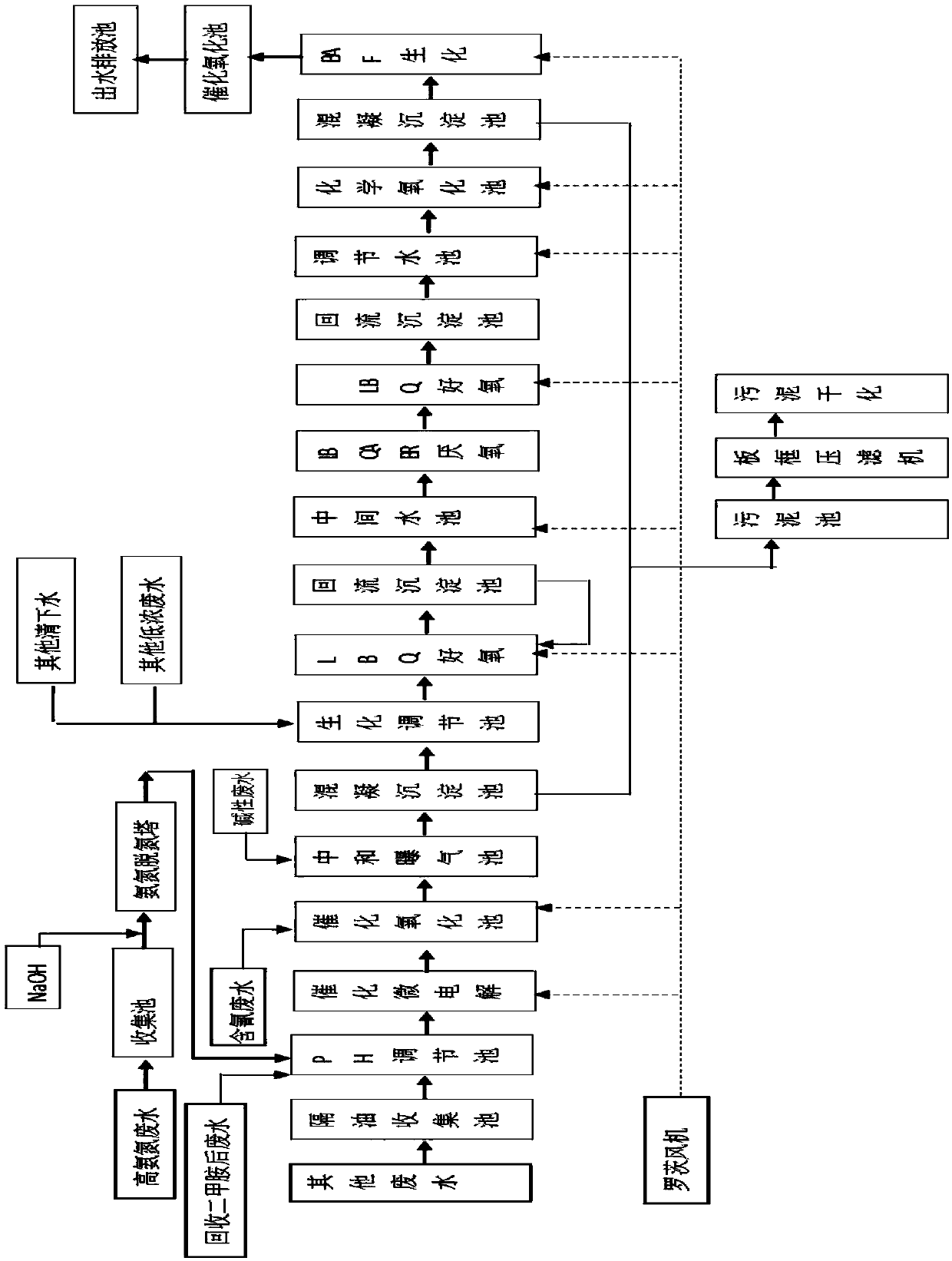

[0036] Pesticide chemical wastewater treatment process: Pesticide chemical wastewater treatment process includes the following processes:

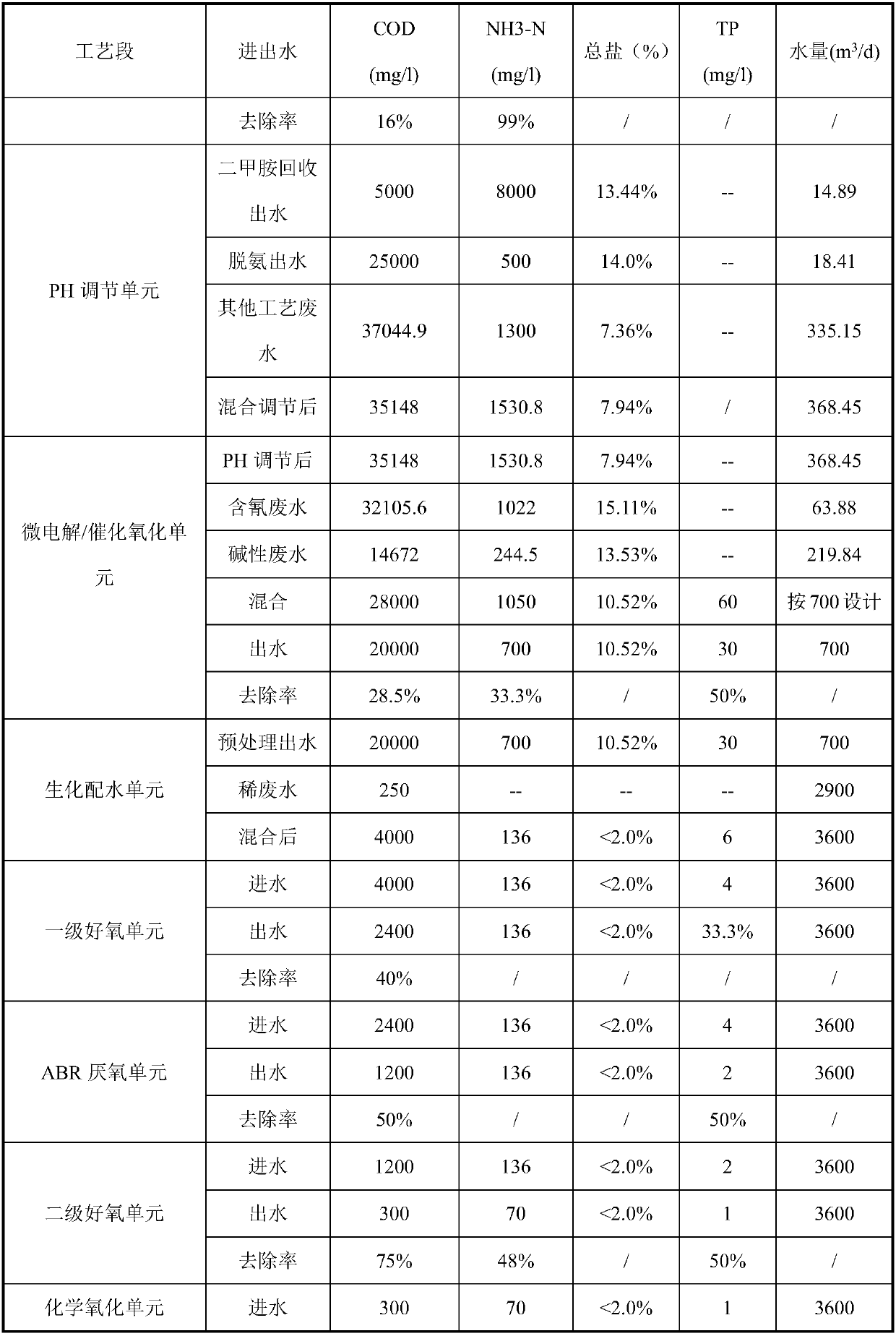

[0037] PH adjustment, micro-electrolysis, catalytic oxidation, LBQ-first-level aerobic, LBQ-ABR anaerobic, LBQ-secondary aerobic, AOP, biological aerated filter, deep oxidation;

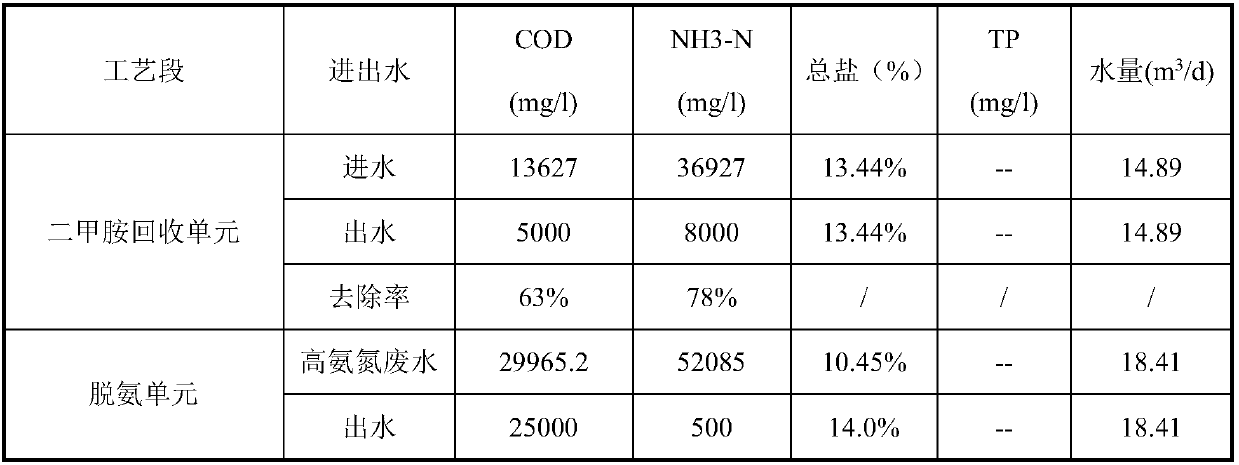

[0038] 1. High-ammonia-nitrogen wastewater is collected separately for deamination, using negative pressure deamination or normal temperature blowing deamination, and then performing physical and chemical pretreatment, and biochemical process for wastewater treatment. After treatment, the effluent ammonia nitrogen is 731-1341mg / L;

[0039]2. After adding 2% mass percentage of hydrogen peroxide (concentration content is 20%), the cyanide-containing wastewater is pumped into the catalytic micro-electrolysis tower with a flow rate of 200 ml / hour,...

Embodiment 2

[0052] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0053] Pesticide chemical wastewater treatment process: Pesticide chemical wastewater treatment process includes the following processes:

[0054] PH adjustment, micro-electrolysis, catalytic oxidation, LBQ-first-level aerobic, LBQ-ABR anaerobic, LBQ-secondary aerobic, AOP, biological aerated filter, deep oxidation;

[0055] 1. High-ammonia-nitrogen wastewater is collected separately for deamination, using negative pressure deamination or normal temperature blowing deamination, and then performing physical and chemical pretreatment, and biochemical process for wastewater treatment. After treatment, the effluent ammonia nitrogen is 731-1341mg / L;

[0056] 2. After adding 3% mass percent hydrogen peroxide (concentration content is 25%), the cyanide-containing wastewater is pumped into the catalytic micro-electrolysis tower with a flow rate of 200 ml / hour, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com