Paperboard conveyor for preventing paperboards from falling and use method thereof

A conveyor and cardboard technology, which is applied in the directions of transportation and packaging, object supply, pile separation, etc., can solve the problems of cardboard drift, cardboard falling off, and low production efficiency of equipment transmission, so as to achieve the effect of convenient moving and fixing, and avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

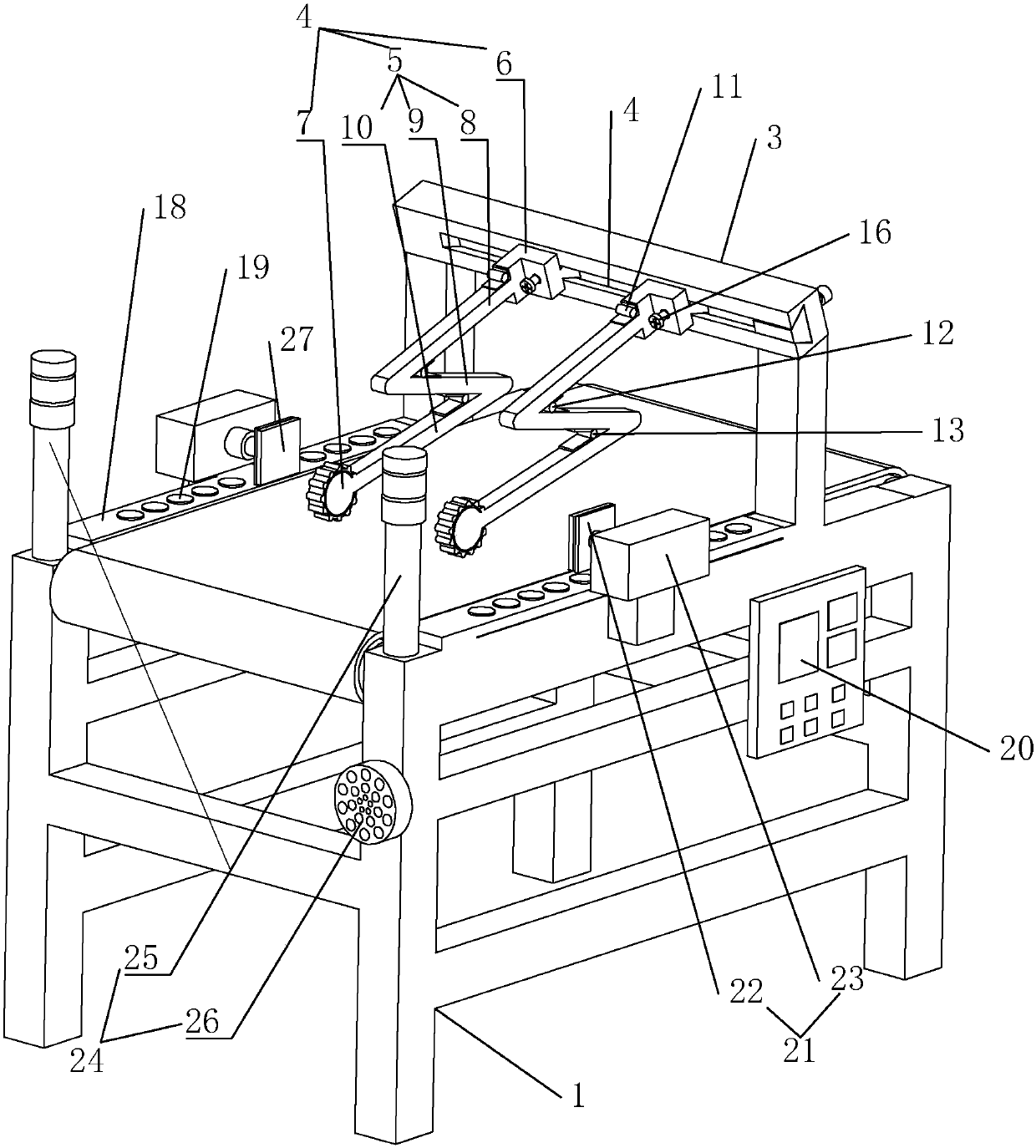

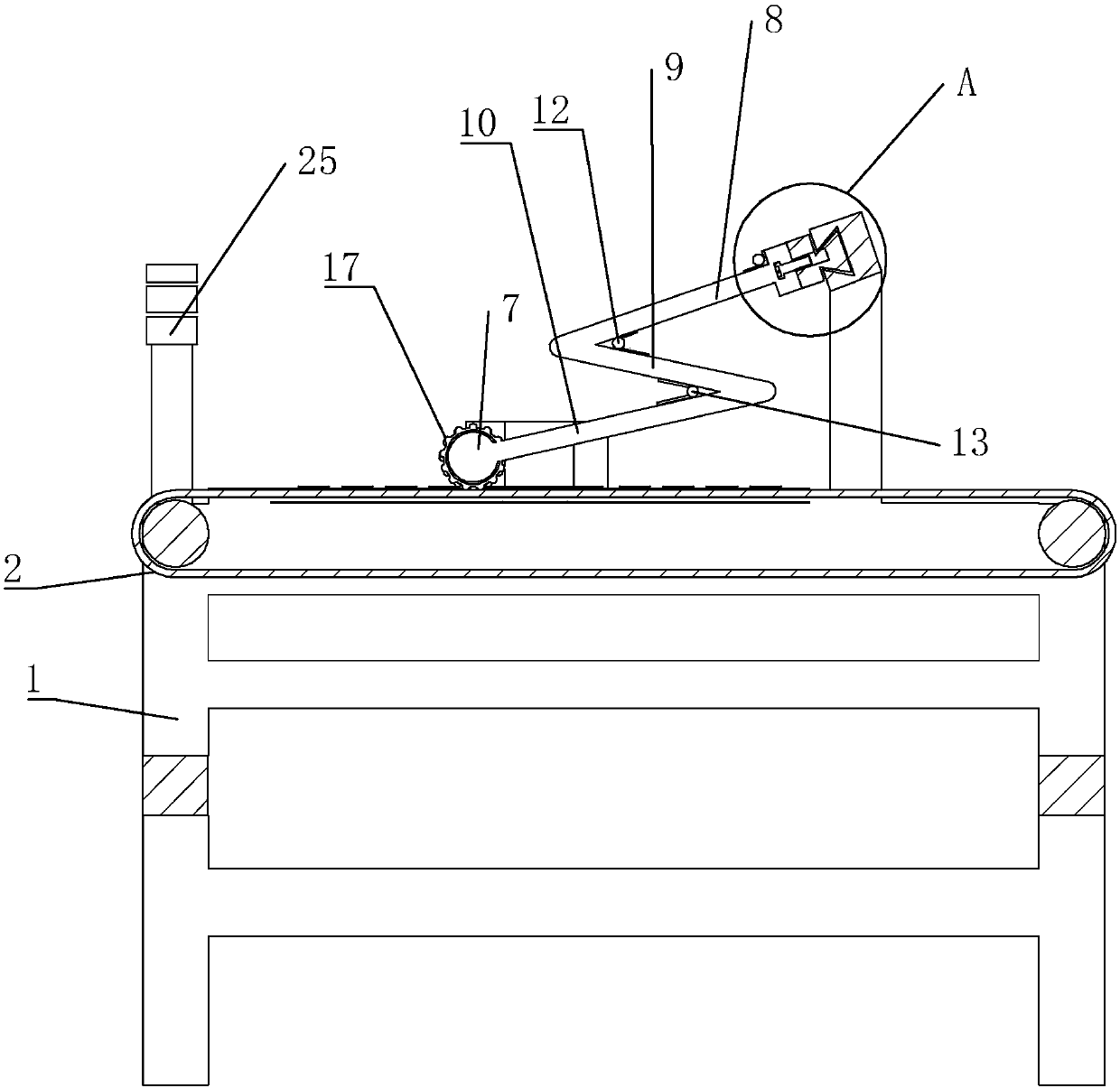

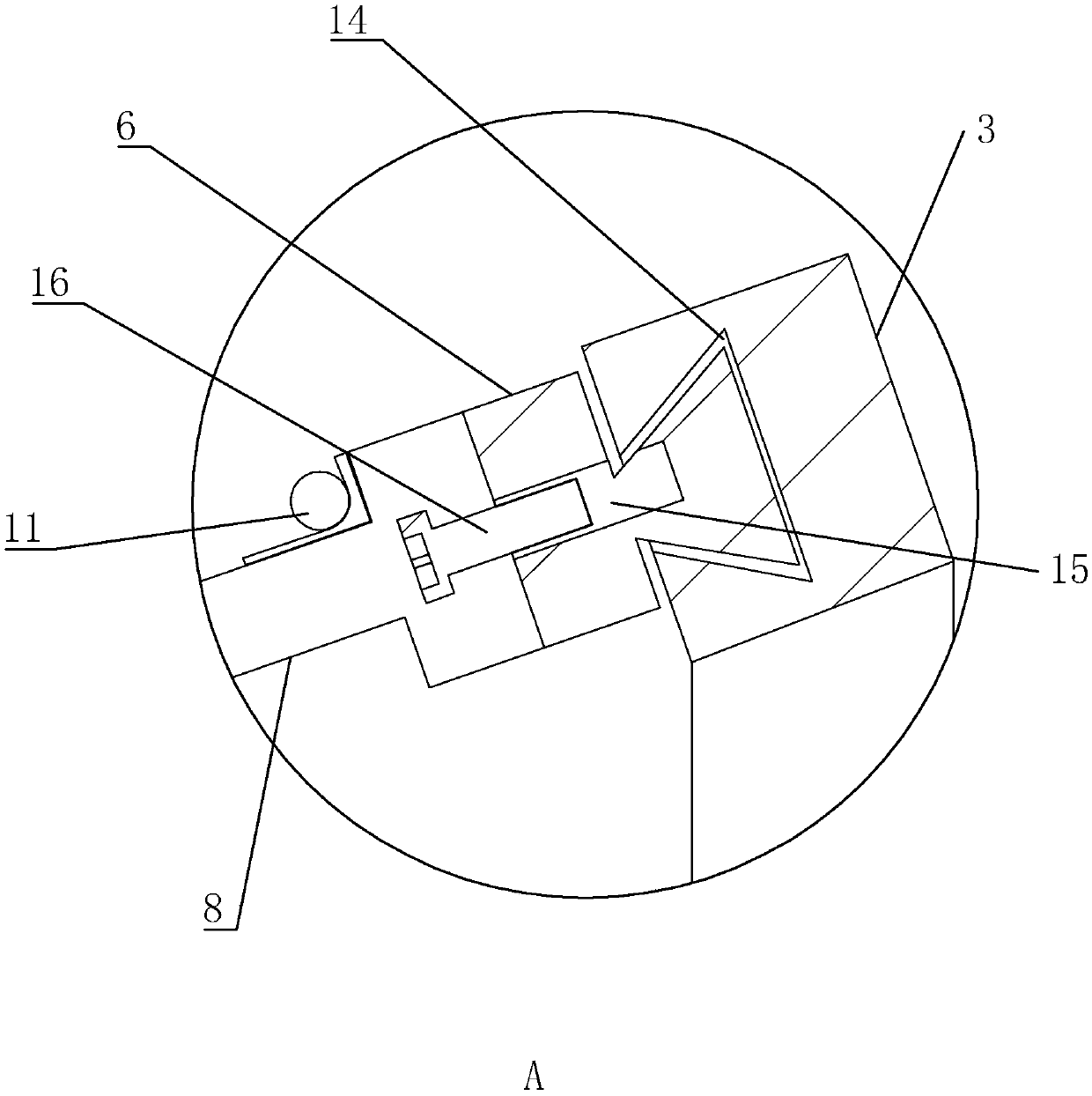

[0037] refer to Figures 1 to 3As shown, a cardboard conveyor for avoiding cardboard falling off in this embodiment includes a frame 1 and a conveyor belt 2 arranged on the frame 1, and the frame 1 is provided with a bracket 3 located on the upper side of the conveyor belt 2 , the bracket 3 is provided with a pressing device 4 that is against the surface of the conveyor belt 2, the pressing device 4 includes a pressing rod 5, a slider 6 and a roller 7, and the pressing rod 5 includes a first pressing rod 8. The second pressing rod 9 and the third pressing rod 10 .

[0038] One end of the first pressing rod 8 is rotatably mounted on the slider 6, and the first pressing rod 8 is set toward the direction in which the conveyor belt 2 moves, and one end of the second pressing rod 9 is far away from the first pressing rod 8 from the sliding block. One end of 6 is rotationally connected, and the second pressing rod 9 is set against the moving direction of the conveyor belt 2, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com