Processing unit and label printing machine having the processing unit

A technology for processing machinery and racks, applied in printing machines, rotary printing machines, printing, etc., can solve problems such as difficulty in precise adjustment, poor repeat accuracy, and cost structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

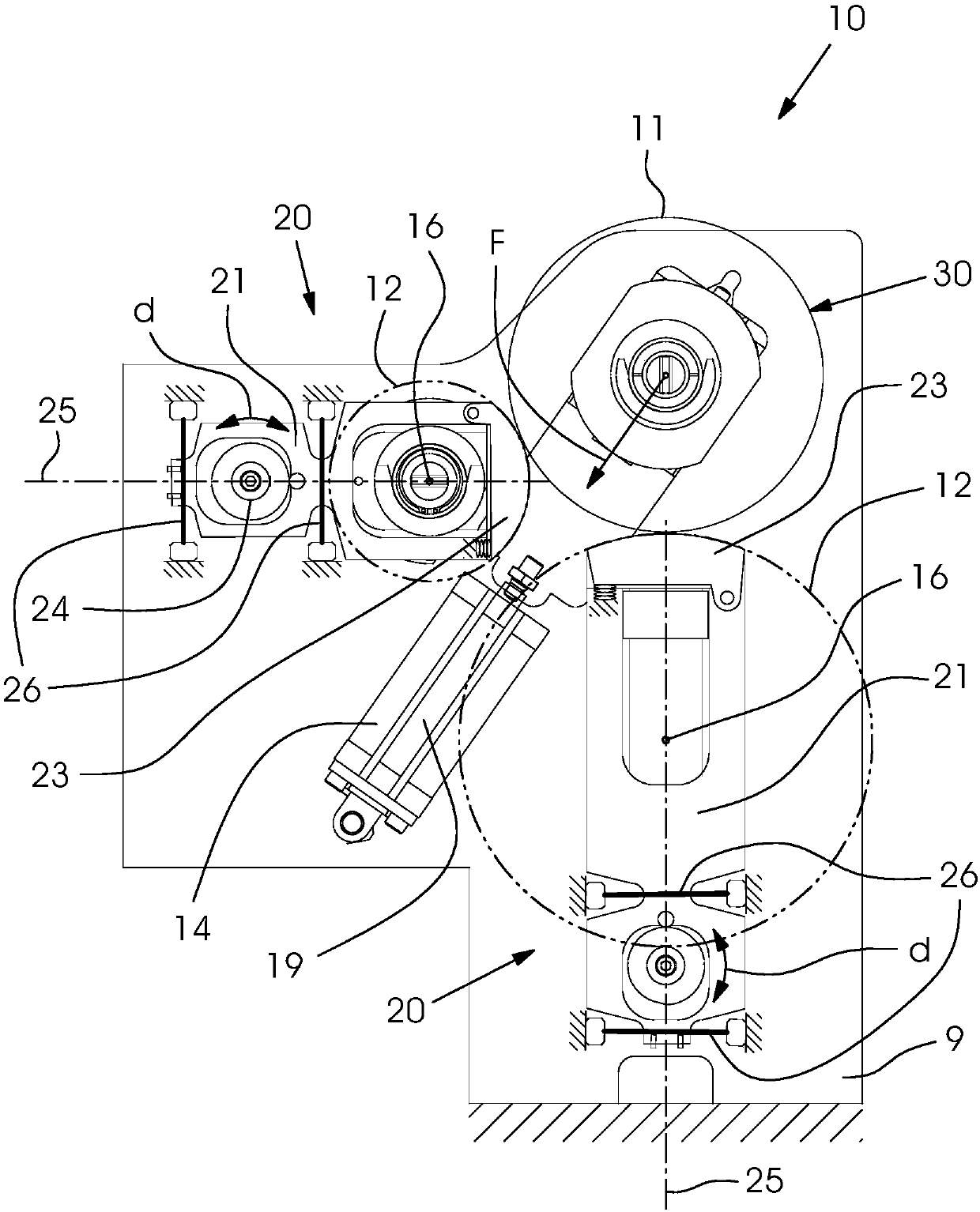

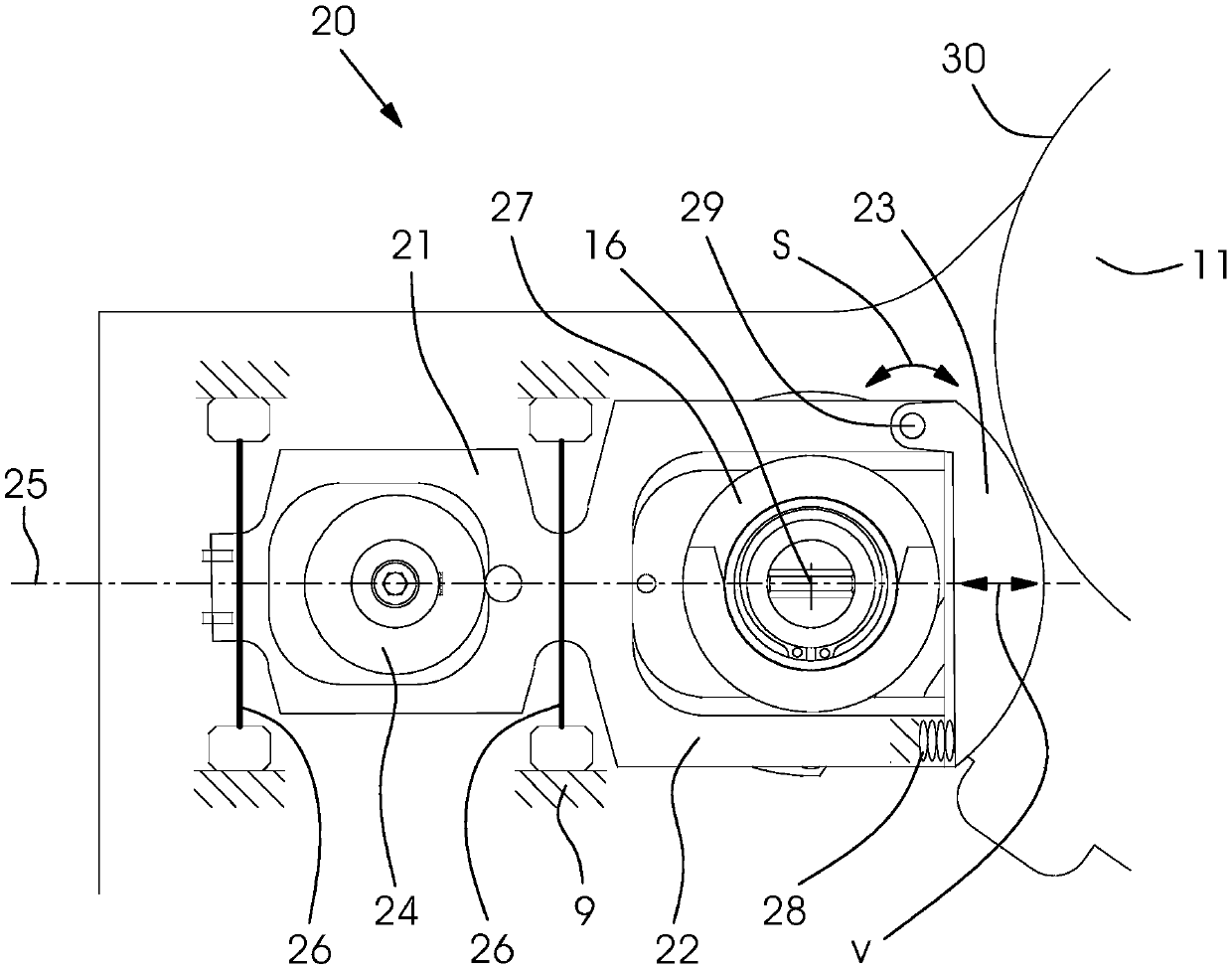

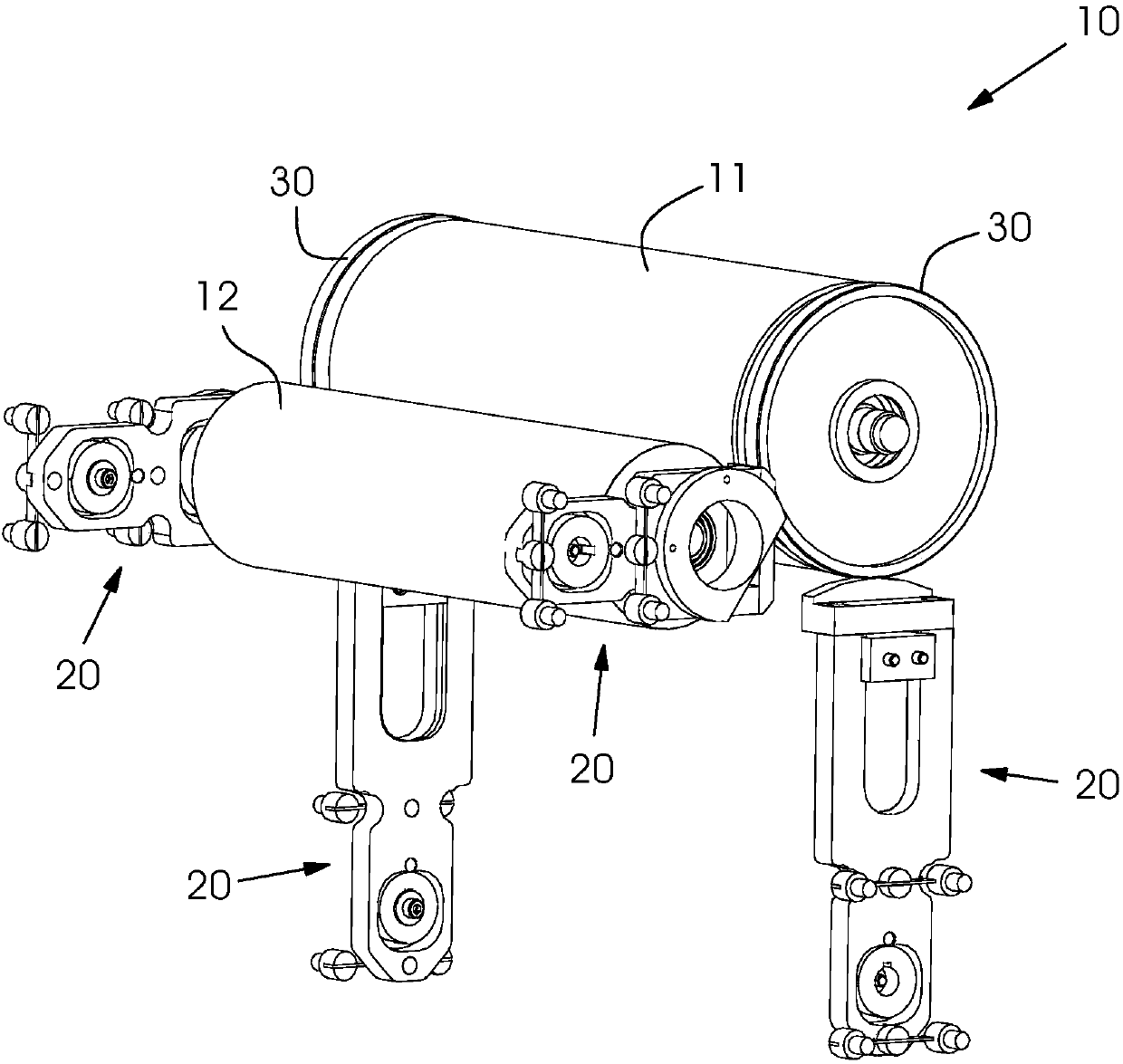

[0027] figure 1 A processing machine 10 is shown which has a first drum 11 , a second drum 12 and a third drum 13 which are mounted in a frame 9 . In the illustrated embodiment, the converting machine 10 is a flexographic printing machine, wherein the first cylinder 11 is embodied as a printing plate cylinder, the second cylinder 12 is embodied as an anilox roller and the third cylinder 13 is embodied as a counterpress. printing cylinder. The second roller 12 and the third roller 13 are mounted stationary in the frame 9 . In contrast, the first roller 11 is mounted movably on a rocker arm 19 in the machine frame 9 . A pneumatic cylinder 14 is installed on the rocker arm 19, and the pneumatic cylinder 14 constitutes a tensioning mechanism, and is used to press the first roller 11 together and press it to the above two fixed rollers 12 with a force F, that is, a pre-tightening force. , 13 on. Axially and on both sides with respect to the first drum 11 , on the axis of rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com