Flooring substrate production system

A production system and base material technology, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve problems such as low automation, low production efficiency, and unstable operation, and achieve a reasonable overall structure setting and improved Production efficiency, safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

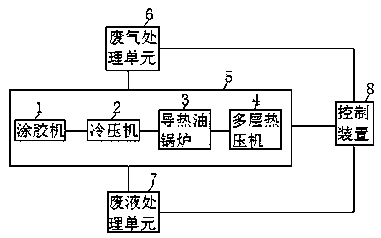

[0009] Such as figure 1 As shown, a floor substrate production system according to the present invention includes a glue spreader 1, a cold press 2, a heat transfer oil boiler 3 and a multi-layer hot press 4 in sequence, and they form a production unit 5. In the A waste gas treatment unit 6 is provided above the production unit 5, and a waste liquid treatment unit 7 is provided below the production unit 5, and the production unit 5, the waste gas treatment unit 6 and the waste liquid treatment unit 7 are all connected to the control device 8; Said production unit 5 is provided with at least one. The overall structure of the present invention is reasonably set up, adopts a production unit composed of a gluing machine, a cold press, a heat-conducting oil boiler and a multi-layer hot press, realizes automatic and stable operation through a control device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com