Stage leveling device improving leveling maintenance and used for high performance mask aligner

A technology of mask alignment and worktable, which is applied to the photoengraving process, instruments, originals for photomechanical processing, etc. problems, such as increasing the maximum capacity, making it easy, and reducing the incidence of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Preferred embodiments for more concretely realizing the technical problems to be solved by the present invention will be described below.

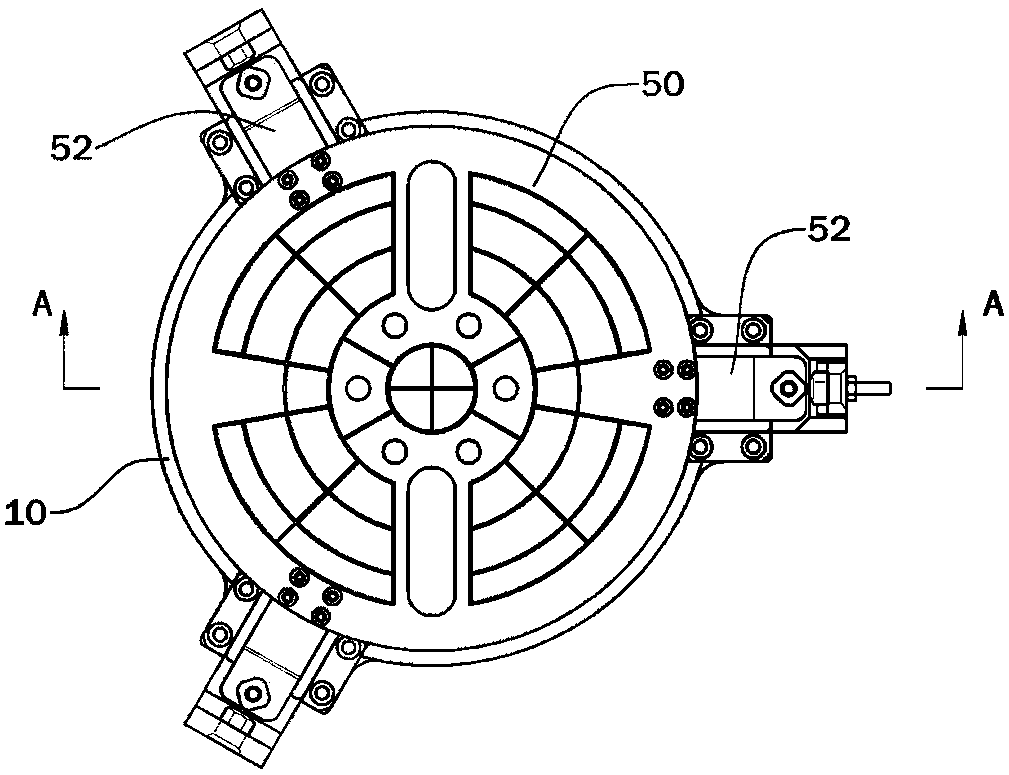

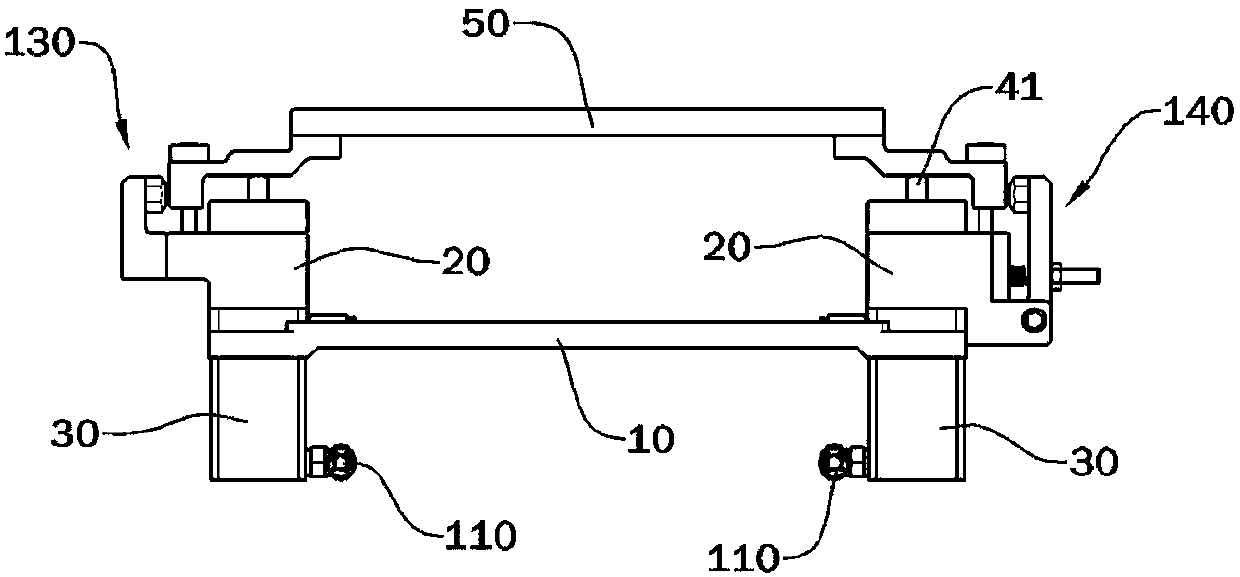

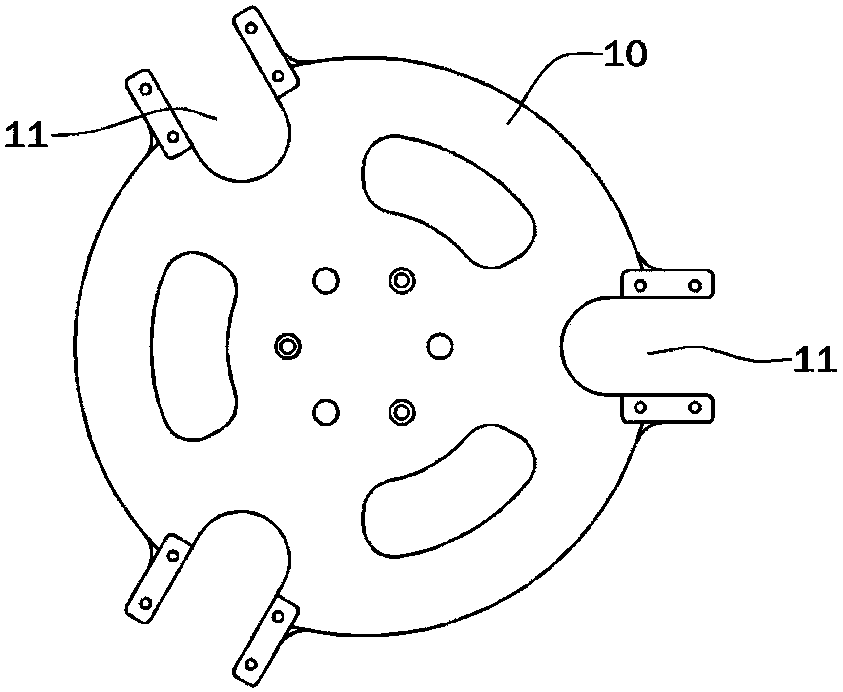

[0049] As can be seen from the accompanying drawings, the overall composition of the preferred embodiment of the present invention includes: a plurality of guide blocks 20, a plurality of leveling air pushers 30, a plurality of leveling rods 40, a wafer table 50, a plurality of guide bolts 60, a ring Housing, 70, lock ring 80, locking control cylinder 90.

[0050] Next, a more detailed description will be given so that the present invention constituted by the above-mentioned outline can be more easily implemented.

[0051] The substrate 10 of the present invention is arranged in a manner capable of moving in the up and down direction by means of the disclosed up-and-down moving device. On the upper end of the substrate 10, there are 120° intervals spaced apart from each other along the circumferential direction. There are a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com