Current measurement device and method facing three-phase four-wire system balanced load

A current measurement device, three-phase four-wire system technology, applied in the field of measurement, can solve the problems of increased core loss, damage to the insulation layer, measurement distortion, etc., and achieve the effects of improved service life, low energy consumption, and convenient installation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

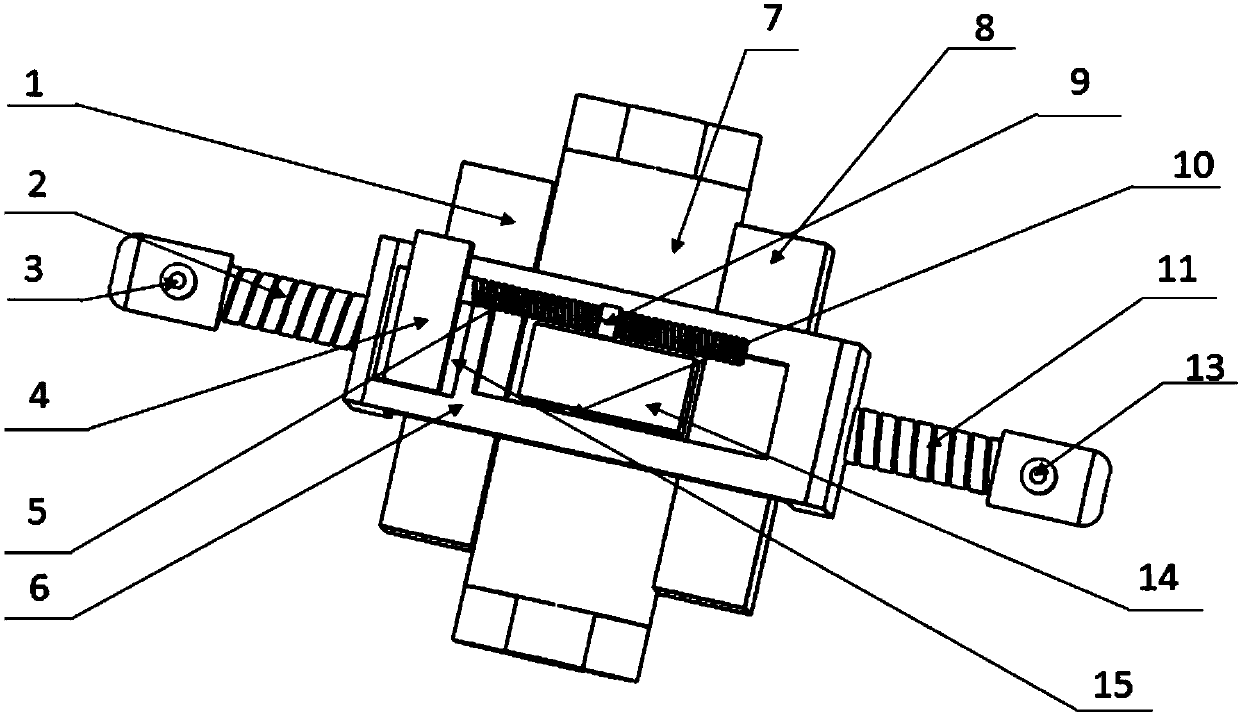

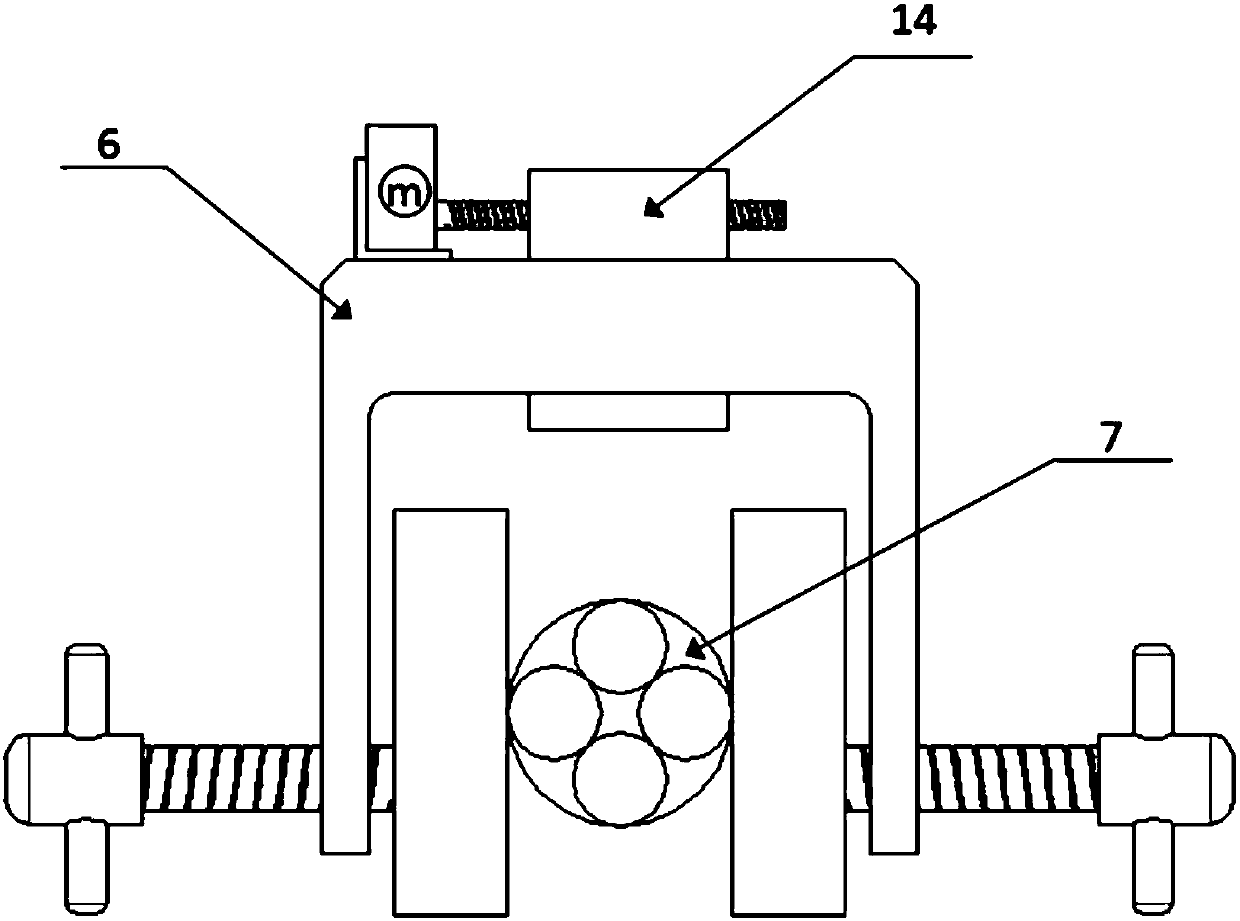

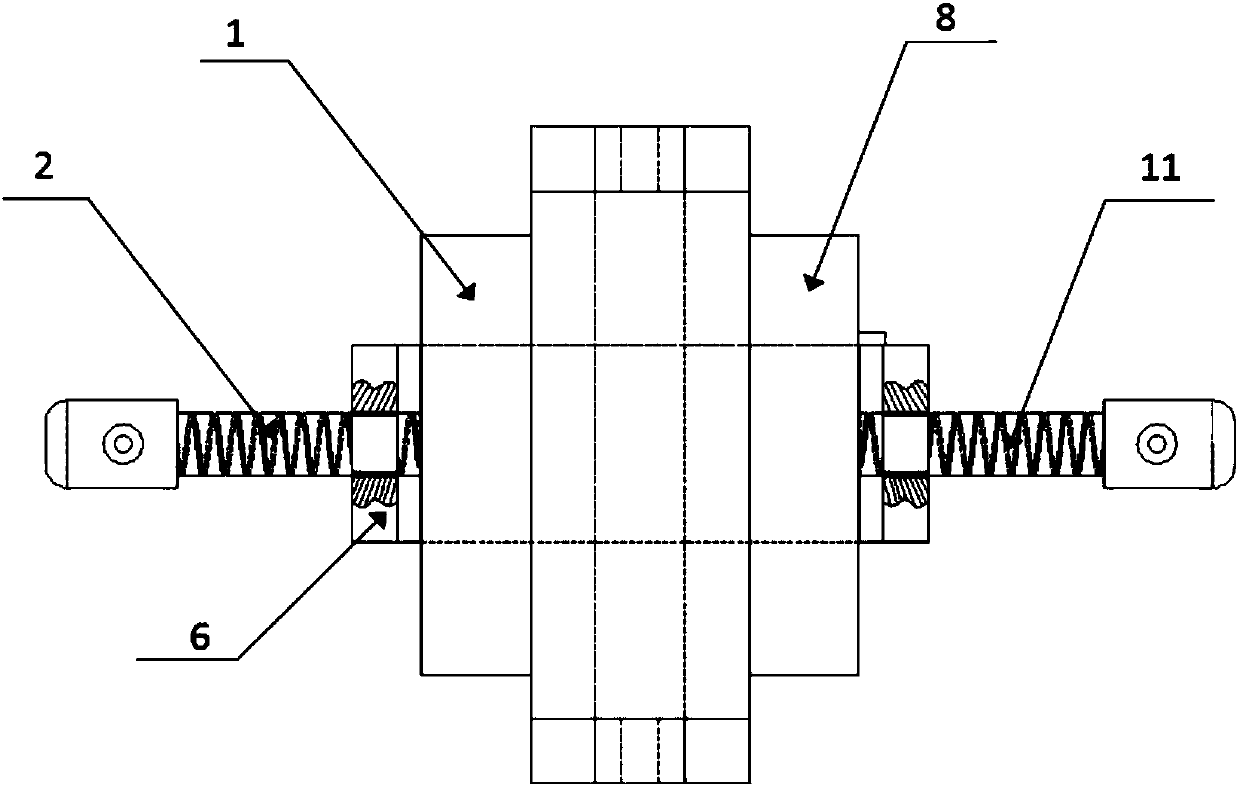

[0038] One end of the left side threaded guide rod 2 is fixedly connected with the left side rectangular block 1, and the other end is covered with a left hand handle 3, and one end of the right side threaded guide rod 11 is fixedly connected with the right side rectangular block 8, and the other end is covered with a right hand handle 3. Side manual turning handle 13, U-shaped frame 6 and left threaded guide rod 2, right side threaded guide rod 11 are all threaded connections, there is a pair of straight line keyways in U-shaped frame 6, turn the left side manual turning handle 3 and the right side manual Rotating handle 13 can make the left side threaded guide rod 2 and the right side threaded guide rod 11 push the left side rectangular stopper 1 and the right side rectangular stopper 8 linear reciprocating motion respectively, the left side rectangular stopper 1 and the right side rectangular stopper 8 can make the wire 7 be clamped, the linear motor 4 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com