Fresnel matrix THz wave propagation model based high-precision thickness detection method for coatings

A coating thickness and thickness detection technology, used in measuring devices, instruments, optical devices, etc., can solve the problems of poor efficiency, undetectable, and low coating thickness detection accuracy, and achieve high-precision detection and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0097] 1. Experiment uses the coating high-precision thickness detection method based on the Fresnel matrix THz wave propagation model provided by the present invention to detect the coating thickness of a metal plate covered by a layer of coating in a part of the area, the physical map of the metal plate Such as Figure 7 shown.

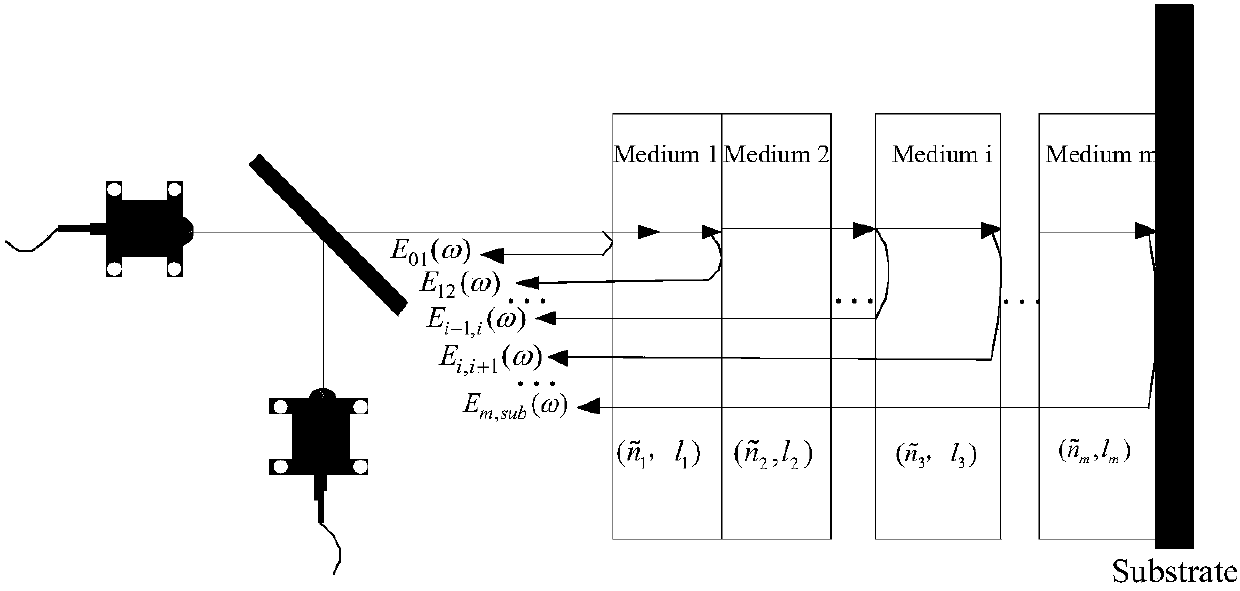

[0098] 2. Starting from the theoretical model of the electromagnetic field, a one-dimensional electric field model of the reflective propagation of the normal incident THz wave in the single-layer dielectric structure is established according to the reflective THz time-domain spectroscopy system used to detect the coating thickness.

[0099] 3. Introduce the Fresnel coefficient matrix method to obtain the Fresnel matrix THz wave propagation model.

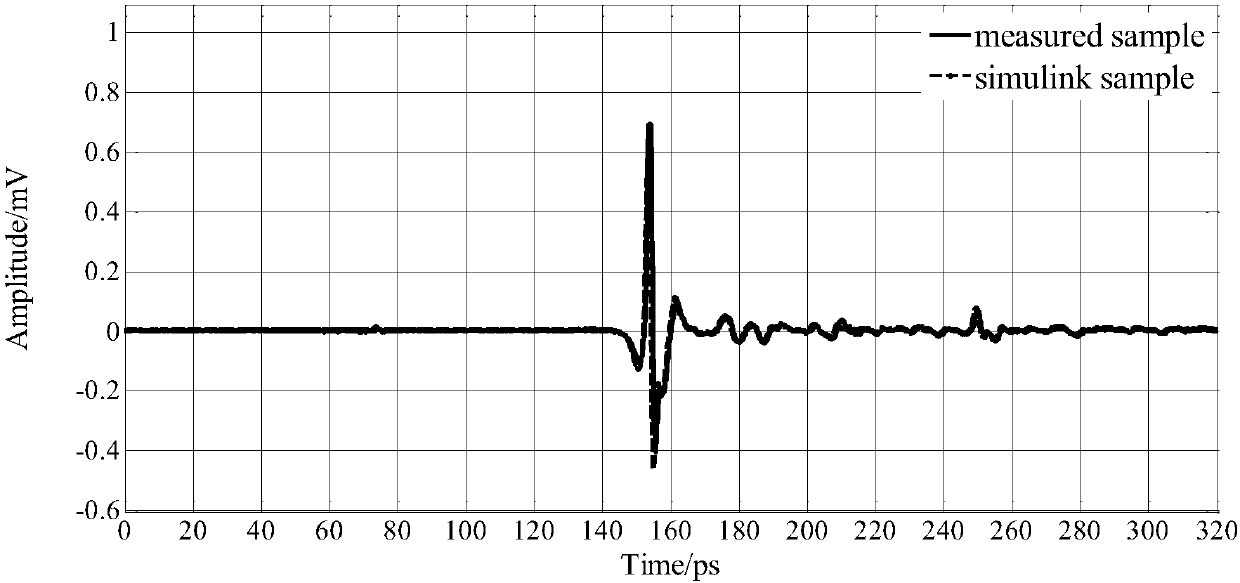

[0100] 4. Compare the waveform obtained by simulation with the measured waveform, and compare with image 3 For comparison, the accuracy of the Fresnel matrix THz wave propagation model is verified.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com