A washing machine with steam washing function

A washing machine and functional technology, applied in the field of washing machines, can solve the problems of complex steam temperature control, intermittent steam, poor application value, etc., and achieve the effects of large steam volume, energy saving and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

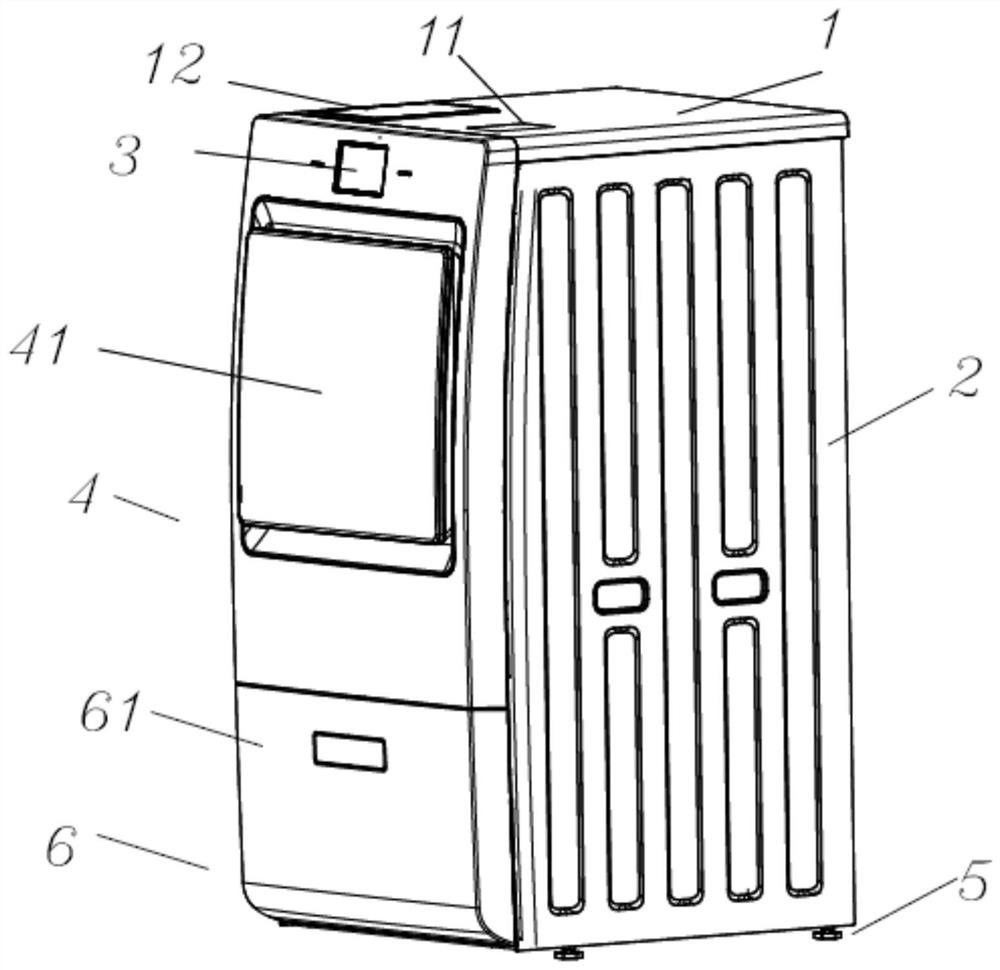

[0038] Reference figure 1 The washing machine having a steam washing function is similar to the prior art, such as including the upper panel 1, and the side panel 2, the side panel 2, and the side panel 2, provided in the surface of the washing machine bottom plate. The foot 5 for supporting the washing machine is used to perform the washing machine operation setting.

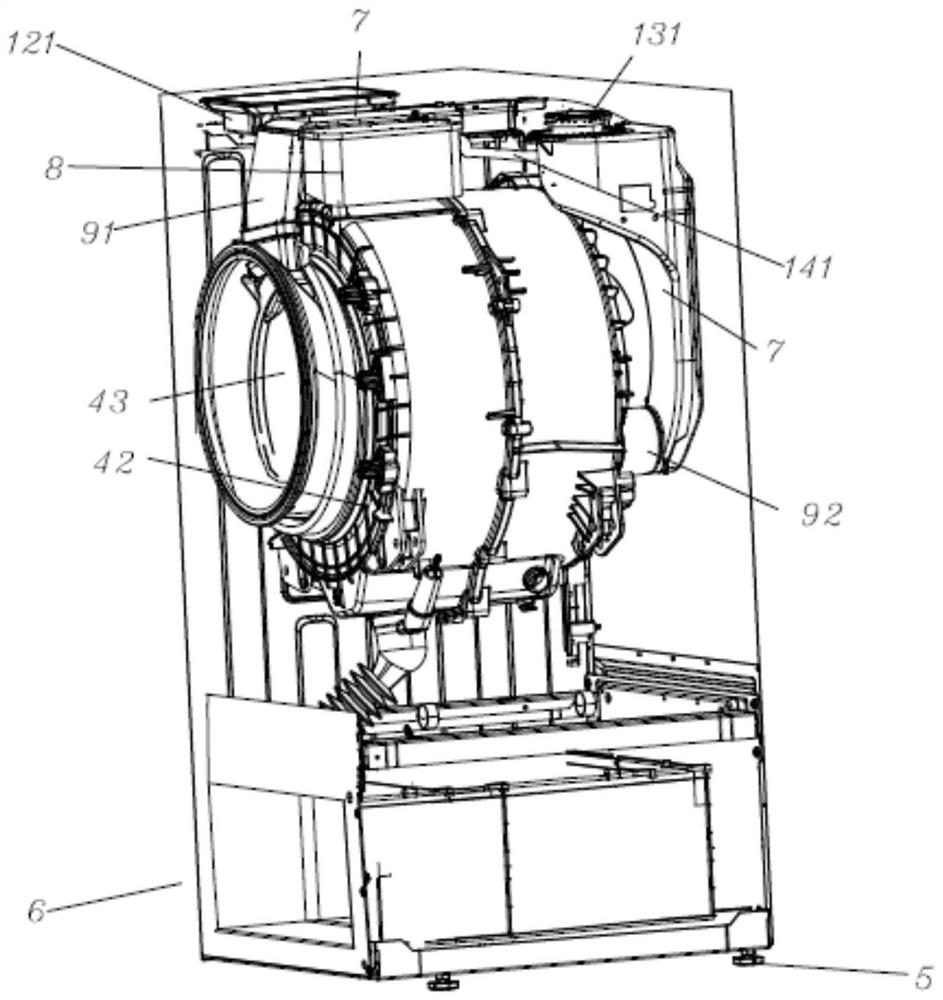

[0039]This embodiment has two washing care units, and the first washing care unit 4 is provided with the first door body 41, and the opening door body 1 41 can be washed into the washed inner barrel; second care The unit 6 is provided with a second door body 61 that can be completely equivalent to the first washing care unit, or relatively simple settings, for example, a care unit that can be used for sterilization, flavored or wrinkle Do not have to set the wash bucket. In the prior art, the arrangement of a plurality of washing care units, based on the core technology of the technical solution of the present inve...

Embodiment 2

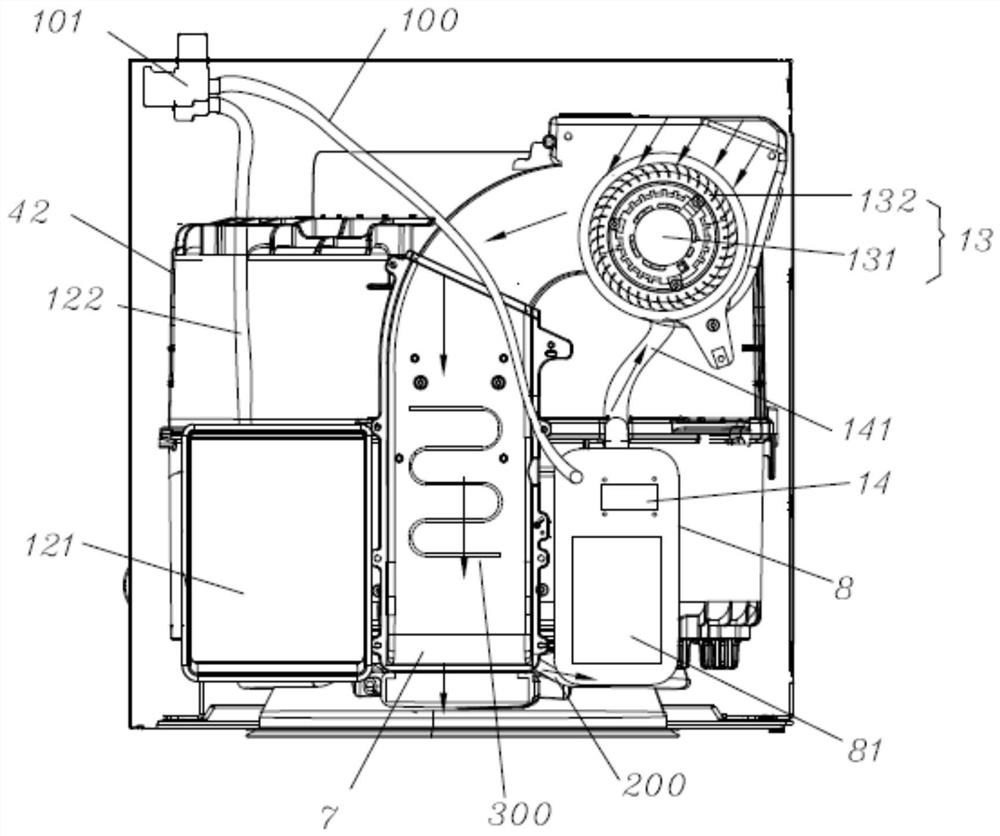

[0067] The difference between the technical solution and the embodiment is that the heating element of the atomizing water generated by the heating atensizer is different, and the heating element employed is a heat pump unit including the compressor and the condenser module. Other technical solutions are the same as the embodiment, and only the distinction will be described in detail below.

[0068] In this embodiment, the heating element is a heat pump unit including a compressor and a condenser module, wherein the condenser module is disposed inside the air, the compressor is disposed between the wash outer tub and the outer casing, which technology The solution can also achieve the beneficial effects of the serpentine heating tube similar to the first embodiment. The laundry machine of the present embodiment produces steam speed, large steam is large and continuous, facilitating the purpose of steam washing, which is costly, and the prior art is low.

[0069] The heating elemen...

Embodiment 3

[0071] The difference between the technical solution and the embodiment is that the foil is different from the specific connection portion of the wash outer tap, which is not connected to the portion of the barrel of the barrel, but is connected to the wash outer tap. On both sides of the intermediate portion of the barrel, the wind can be circulated to flow.

[0072] Other technical solutions are consistent with the embodiments, which will not be described here.

[0073] According to the example technical solution, the washing machine having a steam washing function is large, and the steam is stable, the laundry or care of the clothes is good, and the effective effect of approximation is achieved in general.

[0074] The washing machine having a steam washing function is more simple, saving cost, low energy consumption, and has a good market application value in prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com