Recycling tank for bauxite sewage

A technology for recycling tanks and bauxite, which is applied in water/sewage treatment, mining wastewater treatment, water/sludge/sewage treatment, etc. It can solve the problems of difficulty in discharging crystallizers, and achieve convenient and fast discharging and reduce friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

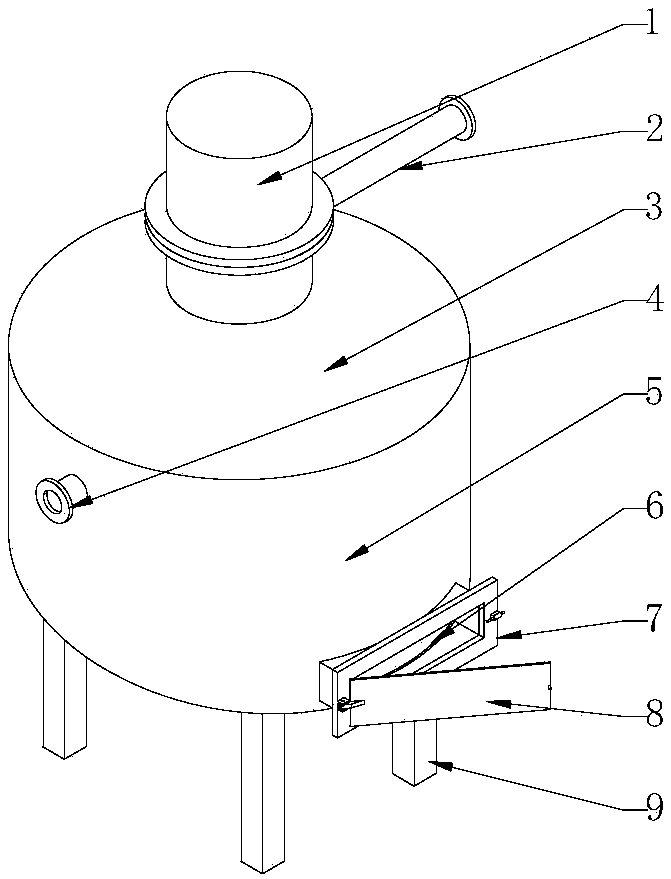

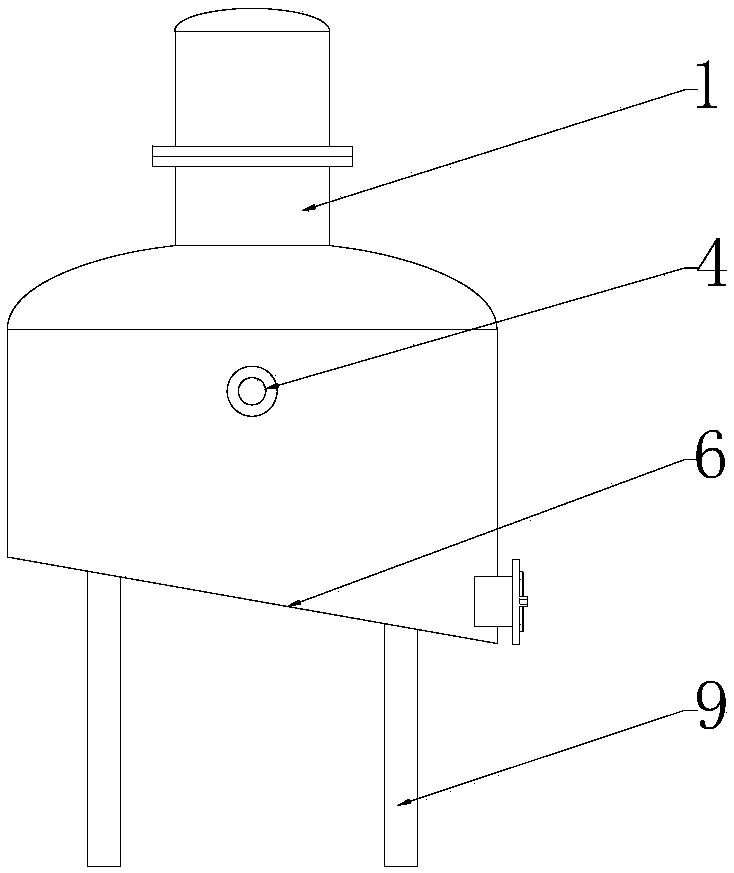

[0019] Embodiment 1: as figure 1 As shown, a recovery tank for bauxite sewage includes a tank body, a liquid inlet pipe 2 and a discharge port 7 located on the tank body, an agitator 1 is installed in the tank body, and feet are provided at the bottom of the tank body 9. The tank body includes an oval plate 6, a cover 3 and a surrounding wall 5 connecting the oval plate 6 and the cover 3. The liquid inlet pipe 2 is located on the upper part of the cover 3, on the side opposite to the liquid inlet pipe 2. The surrounding wall 5 is provided with a liquid outlet pipe 4; the shape of the oval plate 6 matches the surrounding wall 5, and the discharge port 7 is located on the side wall at the lowest point where the surrounding wall 5 contacts the oval plate 6 , the outside of the discharge port 7 is hinged with a sealing door 8 that seals the discharge port 7, and the inside of the sealing door 8 is provided with a sealing strip; the mouth of the discharge pipe 4 is provided with a ...

Embodiment 2

[0022] The difference between embodiment 2 and embodiment 1 is that the inclination angle of the oval plate 6 is 15°, and the sealing door 8 is connected with the discharge port 7 by tenon and tenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com