Spiral stirrer for agricultural product processing and using method

A kind of agricultural product processing and spiral technology, which is applied in the direction of mixers with rotating stirring devices, mixer accessories, chemical instruments and methods, etc., can solve problems such as low efficiency, manual shoveling, and difficulty in product discharge, and achieve good market prospects , improved practicability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

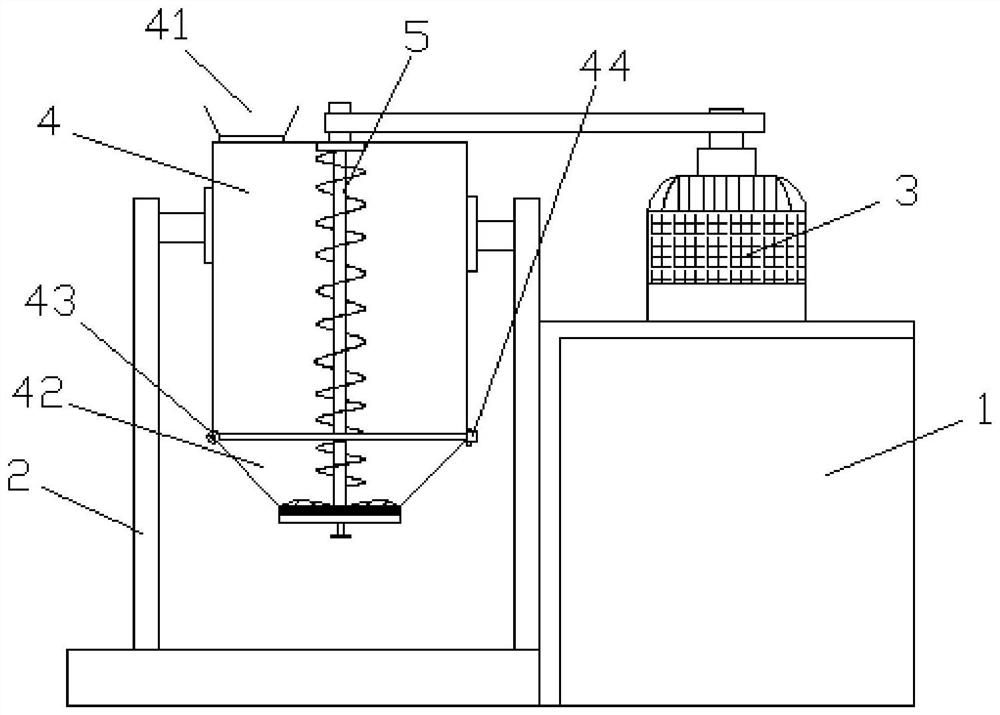

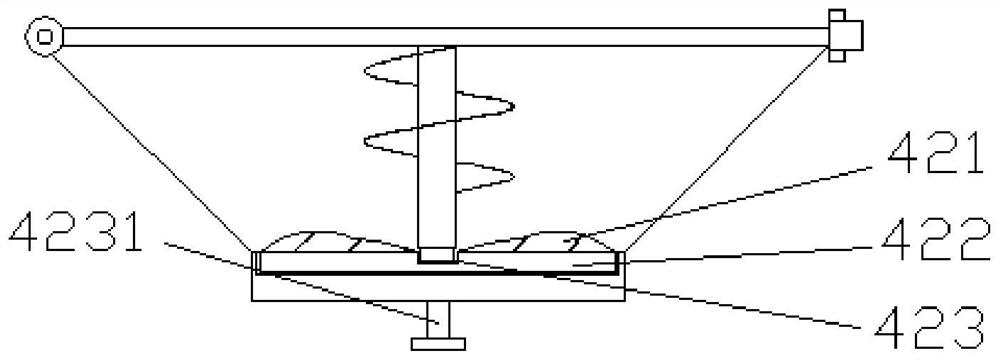

[0020] Example one: Figure 1-Figure 2 Shows a spiral mixer for agricultural products processing, which is mainly composed of a base 1, a support 2, a drive motor 3, a mixing barrel 4, and a mixing shaft 5. The base 1 is placed on one side of the bracket 2, the driving motor 3 is placed on the base 1, the mixing barrel 4 is placed on the supporting frame 2, and one end of the stirring shaft 5 is placed on the base 1. The other end of the mixing shaft 5 in the mixing tank 5 is placed outside the top wall of the mixing tank 4 and connected to the driving motor 3 through a belt. The driving motor on the base makes the mixing shaft of the device be Upper drive; the mixing shaft 5 is provided with a spiral blade 51, through which the material in the mixing tank is stirred; the top of the mixing tank 4 is provided with a feed port 41, and the top feed port feeds materials, which is convenient for operation; The bottom end of the mixing tank 4 is provided with an end cover 41, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com