Vertical shaft rigid guide gap real-time monitoring device and measuring method

A real-time monitoring and distance measuring device technology, applied in the direction of transportation, packaging, elevators, etc., can solve the problems of low efficiency, high labor intensity, cumbersome operation, etc., and achieve the effect of solving time-consuming and labor-intensive, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, innovative features, objectives and efficiency achieved by the present invention easy to understand, the present invention will be further clarified below in conjunction with specific illustrations.

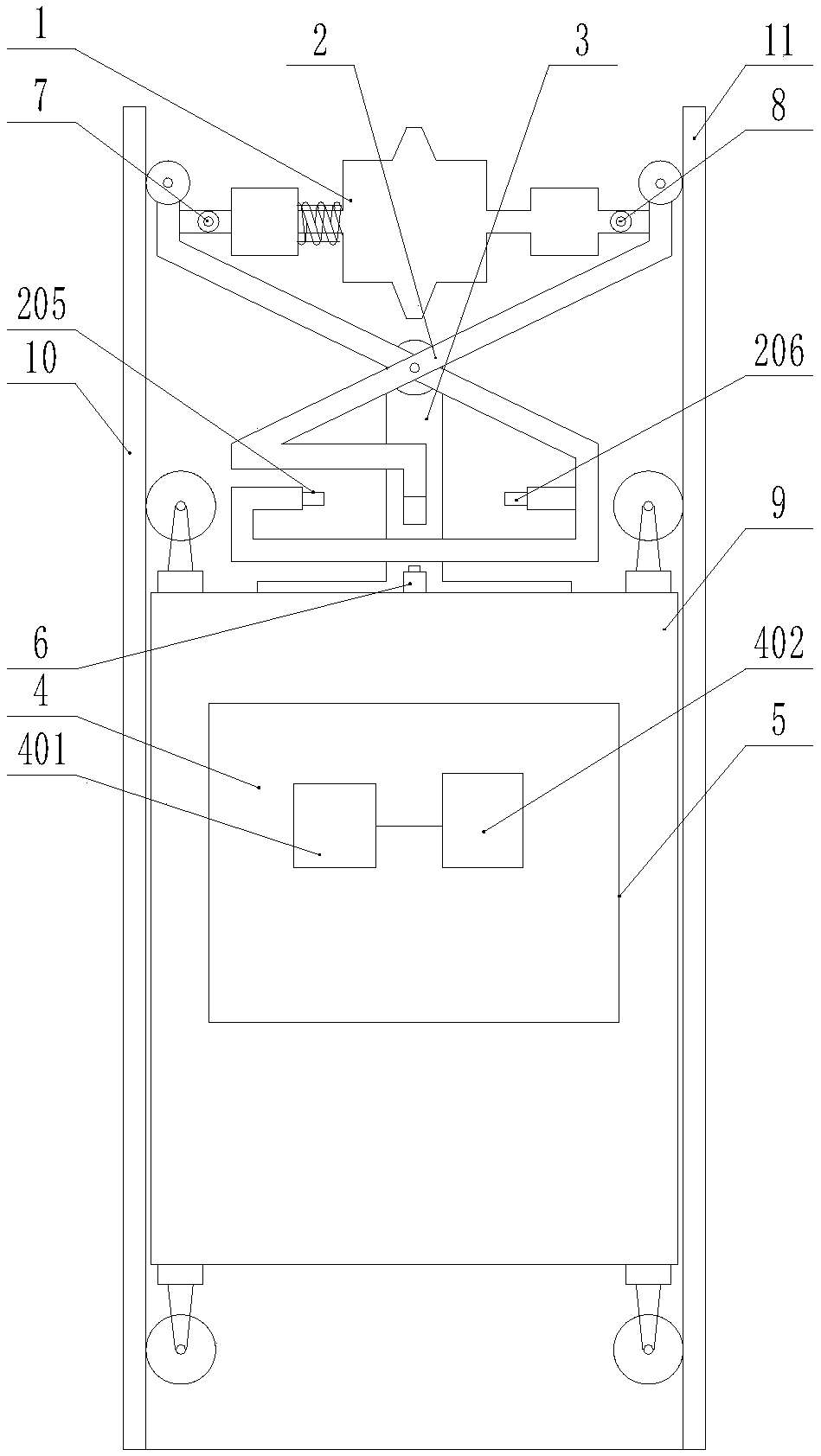

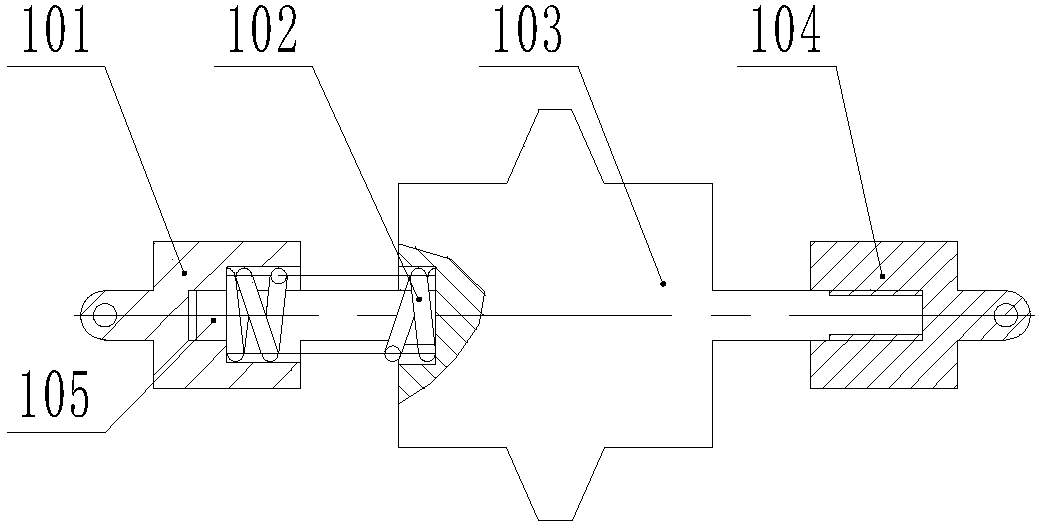

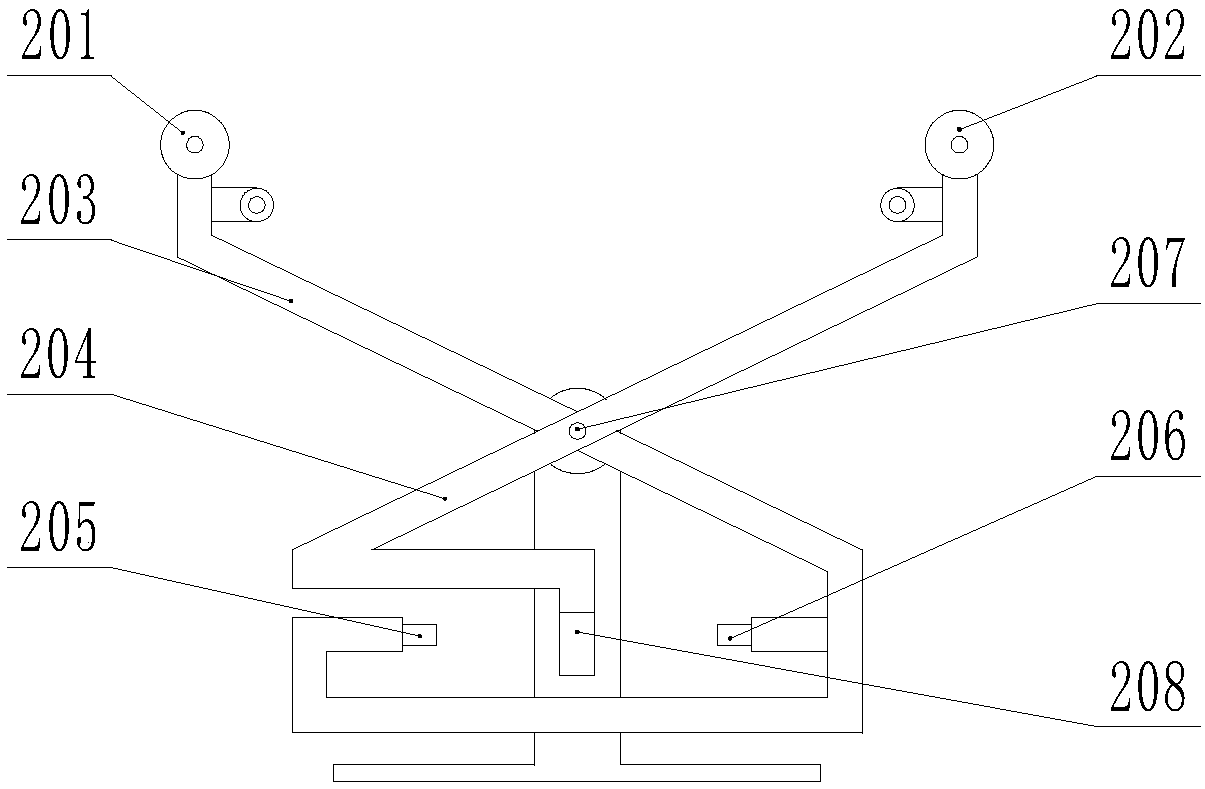

[0017] Such as figure 1 The shown is a real-time monitoring device for the spacing of rigid tank roads in vertical shafts, which is composed of a spacing adjustment device 1, a lever distance measuring device 2, a base 3, a display device 4, an explosion-proof box 5 and a height laser range finder 6. It is characterized in that: the two ends of the distance adjusting device 1 are connected with the two ends of the lever measuring device 2 through a rotating pair; the lever distance measuring device 2 is connected with the base 3 through a rotating pair, the base 3 is fixed on the top of the cage 9, and the height is measured by laser Instrument 6 is fixed on the top of cage 9, display device 4 is fixed in explosion-proof box 5, height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com