Wall cleaning device for construction powder conveyor

A transporter, transport container technology, applied to improve the cleaning effect. , The wall cleaning device of the construction powder conveyor, and the field of the powder tank for construction can solve the problems of poor cleaning effect and achieve the effect of good cleaning effect, raising temperature and enhancing cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

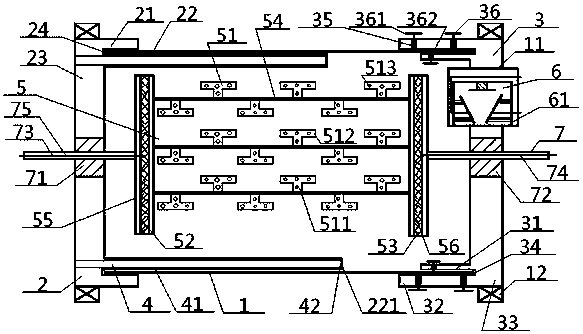

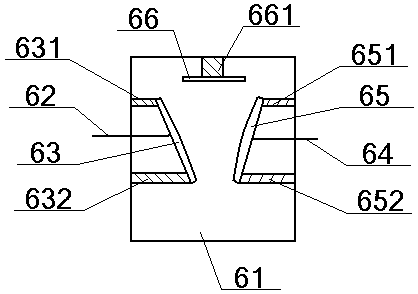

[0027] see Figure 1 to Figure 2, a wall-cleaning device for a construction powder transporter, comprising a transport container 1, a wall-cleaning assembly 5 and a wall-cleaning rotating shaft 7, the interior of the transport container 1 is provided with a wall-cleaning assembly 5, the wall-cleaning assembly 5 The inside of the wall is connected with the middle part of the wall-cleaning rotating shaft 7, and the left and right ends of the wall-cleaning rotating shaft 7 pass through the left and right ends of the transport container 1 and then extend to the outside of the transport container 1;

[0028] The left and right ends of the wall cleaning rotating shaft 7 are respectively connected with the left bearing 71 and the right bearing 72, the left bearing 71 and the right bearing 72 are respectively located in the middle of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com