Air speed controllable electrostatic dust remover

A technology of electrostatic dust removal and dust removal machine, which is applied in the field of industrial manufacturing, can solve the problems of being carried out by the airflow before it settles, the shortcomings cannot be perfectly solved, and the voltage of spark discharge is reduced, so as to increase market competitiveness, good wind speed controllability and Temperature control and life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

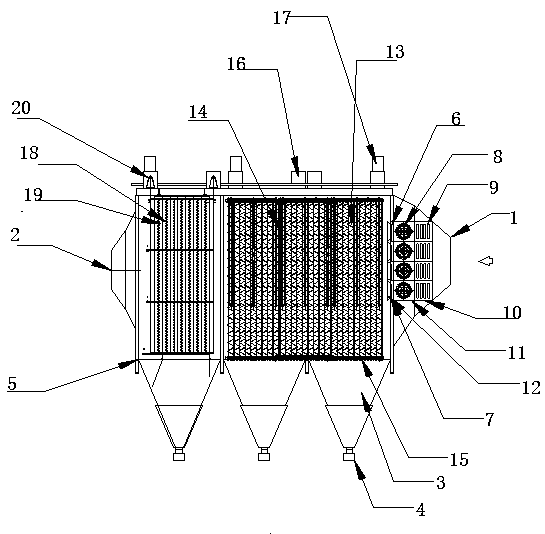

[0016] Embodiment 1: see figure 1, a controllable wind speed electrostatic precipitator, the controllable wind speed electrostatic precipitator includes a shell assembly, a wind speed adjustment assembly, an electrode dust removal assembly and a filter bag dust removal assembly; the wind speed adjustment assembly, an electrode dust removal assembly and a filter bag dust removal assembly All need to be installed in the housing assembly; the wind speed adjustment assembly, motor dust removal assembly and filter bag dust removal assembly are installed in the housing assembly sequentially from right to left. The design structure is simple and clear, the components are closely connected and do not affect each other, the required parts are easy to replace, and it is easy to maintain the product during use in the future; the housing components include the air intake horn 1, the air outlet horn 2, Ash hopper 3, ash outlet 4 and dust collector housing 5; the air intake horn and air out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com