Ultrasonic probe handheld bracket for ultrasonic testing

An ultrasonic probe and ultrasonic detection technology, applied in the direction of ultrasonic/sonic/infrasonic diagnosis, material analysis and application using sound wave/ultrasonic/infrasonic wave, can solve problems such as influence, inaccurate position adjustment method of ultrasonic probe, simple results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

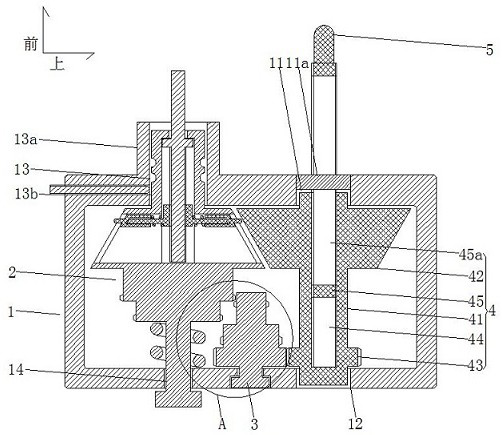

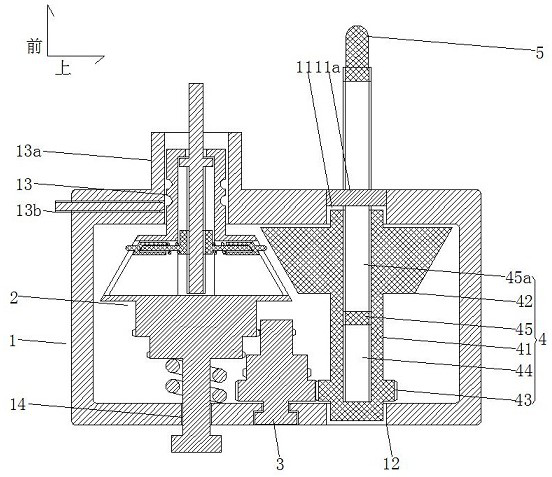

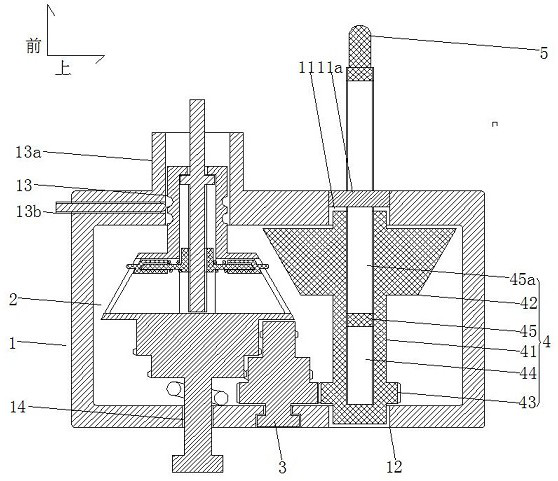

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0056]An ultrasonic probe handheld bracket for ultrasonic testing, comprising a handheld housing 1, an active element 2, a transmission element 3, a driven element 4, and an ultrasonic probe 5;

[0057] The handheld housing 1 is a hollow handheld housing, and the handheld housing 1 includes:

[0058] The front output hole 11 is located above the front end of the hand-held housing 1, and a limit cross bar 11a is arranged inside it;

[0059] The rear output hole 12 is located at the rear end surface of the hand-held housing 1 corresponding to the front output hole 11;

[0060] The front input hole 13 is located below the front end of the hand-held housing 1, the front end of the front input hole 13 is formed with an annular protective sleeve 13a, and the lower end of the hand-held housing 1 is screwed with a shifting screw inserted into the front input hole 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com