Cabling yarn binding machine with stranding mold

A skeining machine and mold technology, which is applied in the fiber mechanical structure, light guide, optics, etc., can solve the problems of low service life of the stranding die and the influence of the overall roundness of the stranding die, so as to ensure the roundness and improve the use. Longevity and effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples.

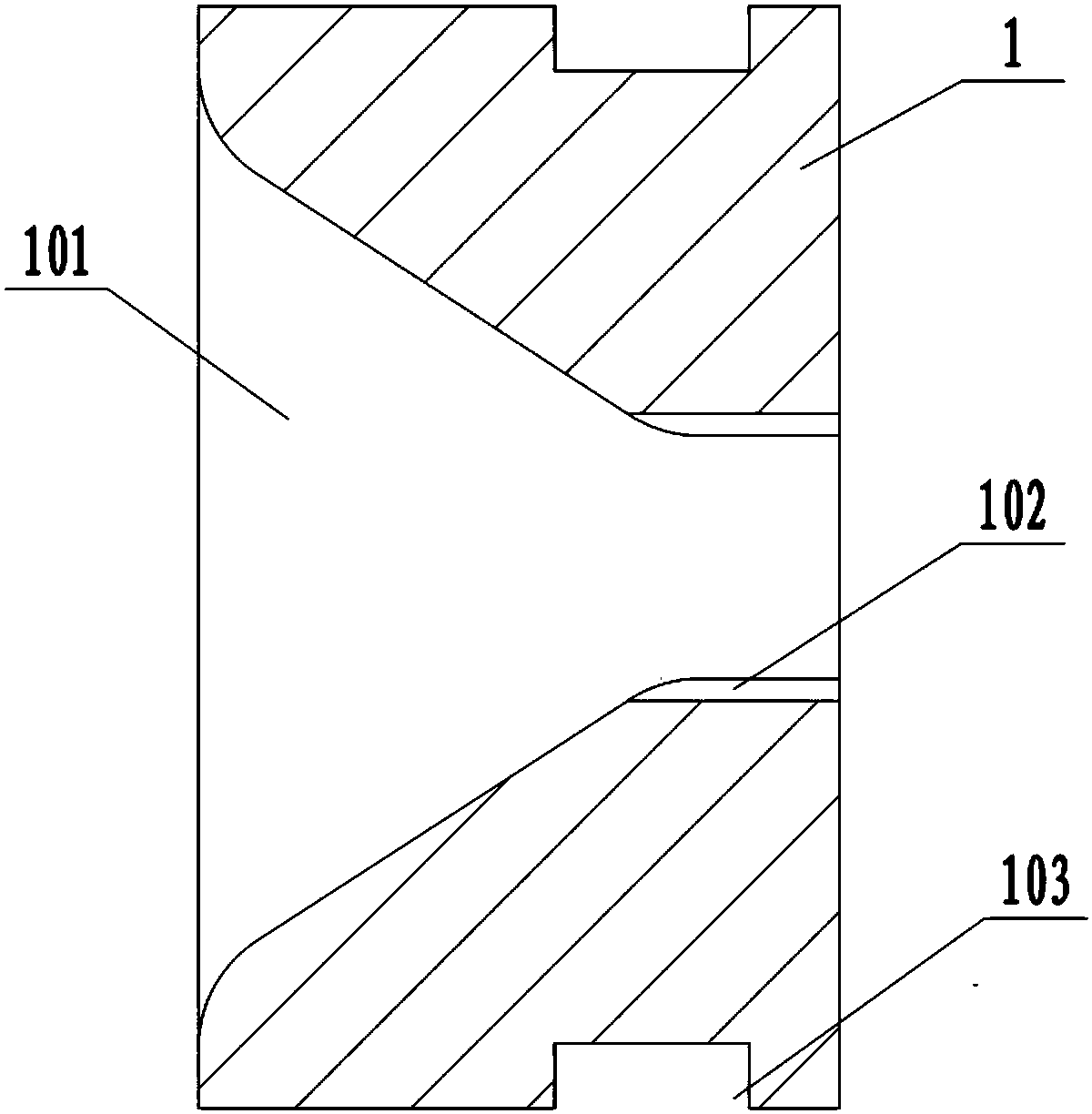

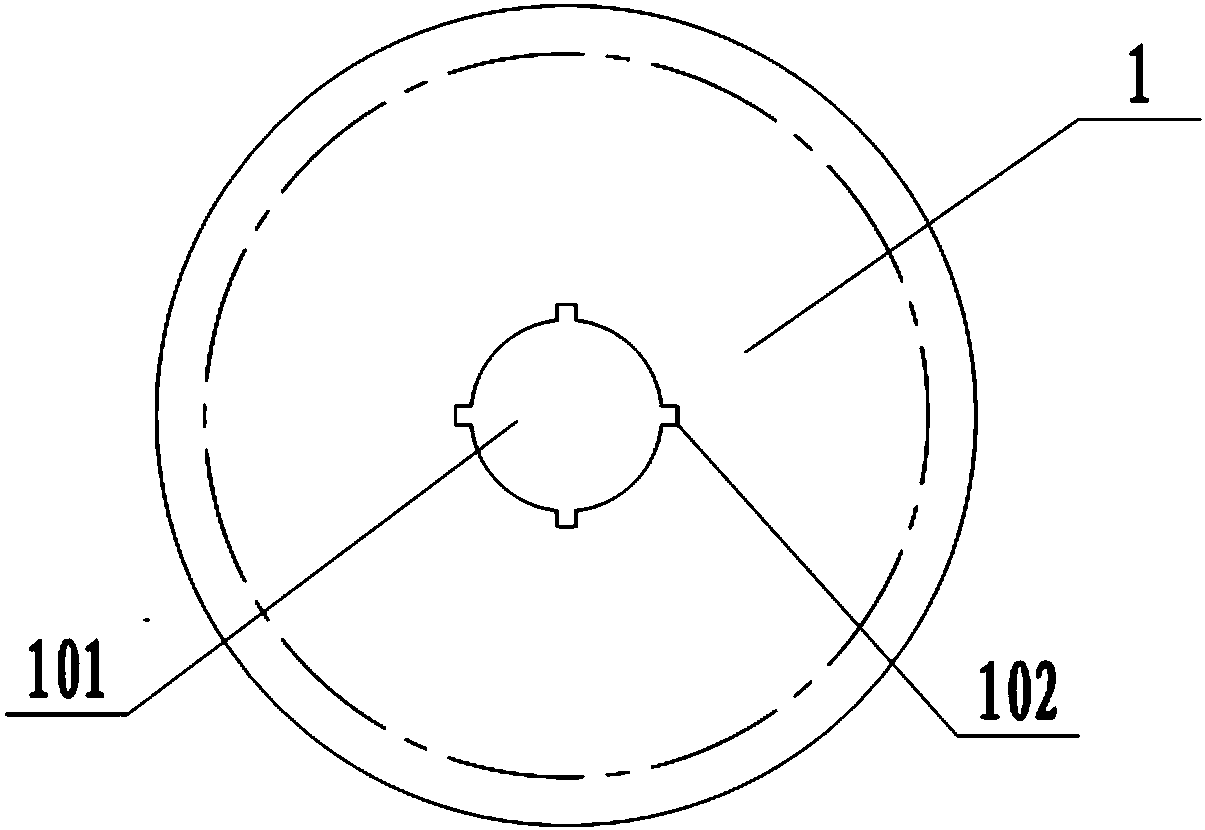

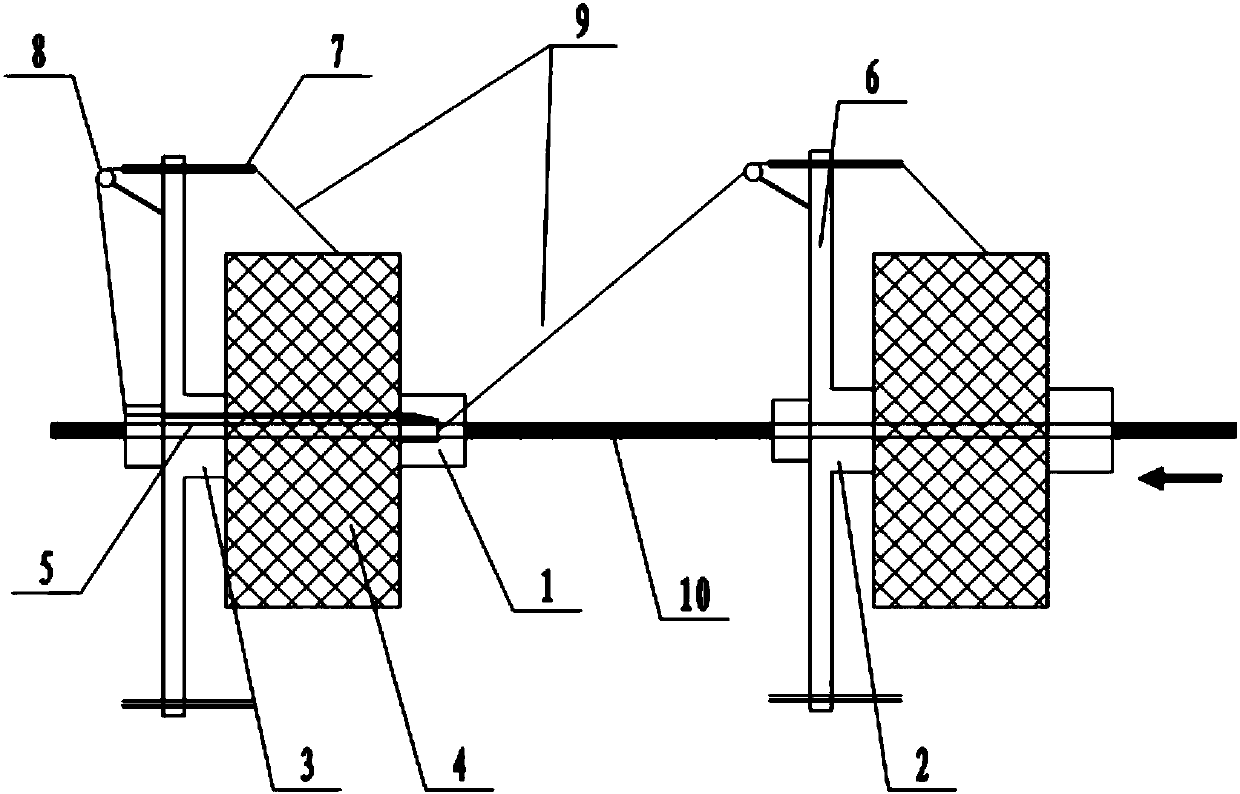

[0028] Such as Figure 1-Figure 3 As shown, a cable binding machine with a twisting mold includes a frame and a mold body, and the first hollow rotating shaft 2 and the second hollow rotating shaft 3 driven by a driving device are installed in rotation on the frame, The driving device can be driven by a driving motor to realize the opposite rotation of the first hollow rotating shaft 2 and the second hollow rotating shaft 3. Since the driving motor drives the rotating shaft to rotate, it is a conventional technical means in the prior art, which is recognized by those skilled in the art. Therefore, it will not be described in detail here. The first hollow rotating shaft 2 and the second hollow rotating shaft 3 are correspondingly arranged, and yarn clusters 4 are wound on the first hollow rotating shaft 2 and the second hollow rotating shaft 3, and the mold body 1 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com