Drill bit special for oil and gas drilling

A technology of oil and gas drilling and drill bits, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc., and can solve the problem of not being able to transfer out the heat of the soil in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

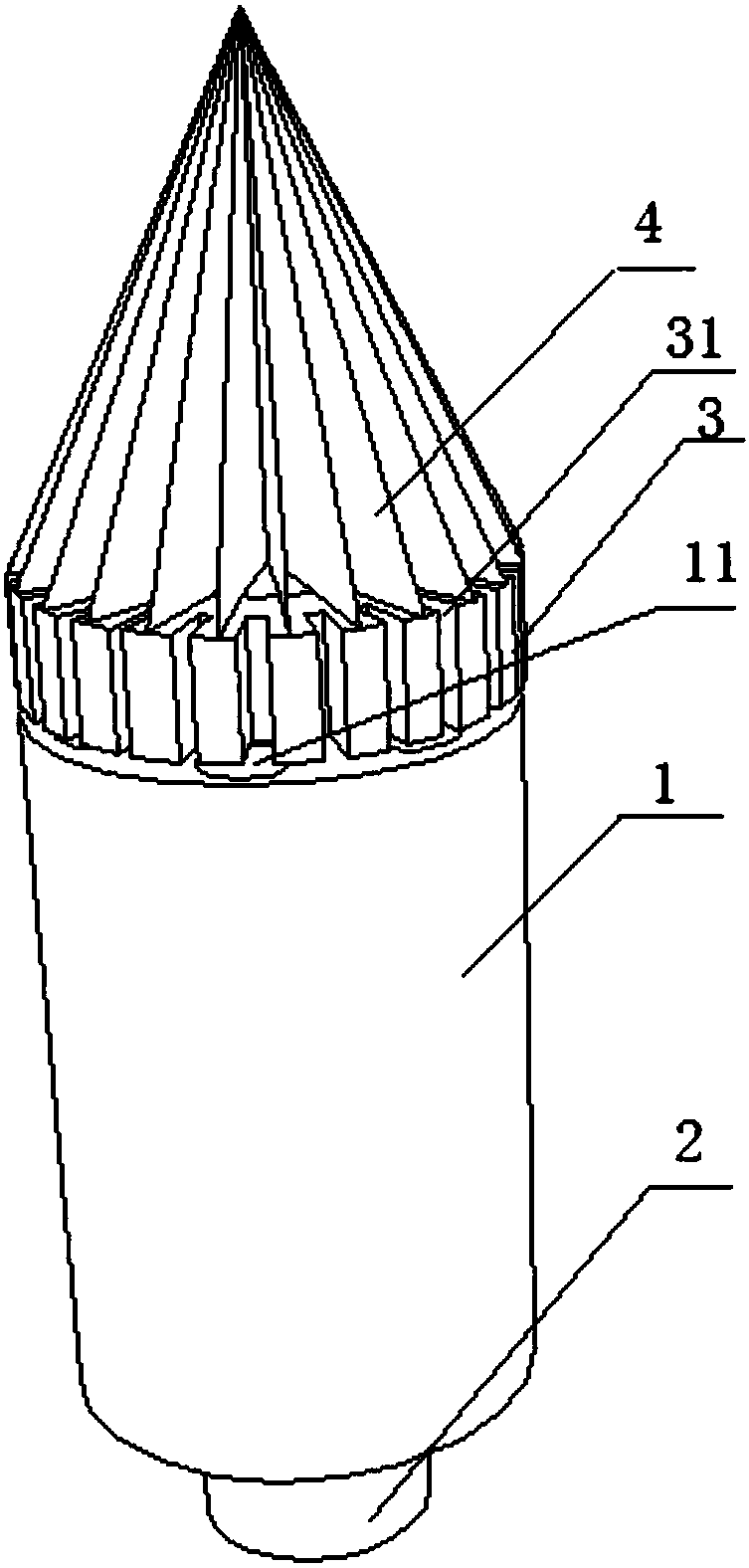

[0015] Such as figure 1 As shown, a special drill bit for oil and gas drilling includes a threaded drill sleeve 1 and a rotating shaft 2, the inner end of the rotating shaft 2 is connected with a drill tip 4, and an outer diameter is passed between the drill tip 4 and the rotating shaft 2 It is connected with the same connecting column 3 as the drill sleeve 1, and the connecting column 3 has several mud flow passages 31 evenly distributed in the axial direction, and the drill tip 4 is composed of several triangular pieces evenly distributed circularly around the end surface of the connecting column 3, The drill sleeve 1 is uniformly provided with a plurality of mud-water through-holes 11 connecting the two ends of the drill sleeve 1 along the circumferential direction.

[0016] Both the drill tip 4 and the rotating shaft 2 are welded with the connecting column 3 .

[0017] The material of the drill sleeve 1 , the rotating shaft 2 and the connecting column 3 is a heat-conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com