Bearing workpiece transfer device based on multi-directional cleaning

A technology for conveying devices and workpieces, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of insufficient cleaning surface and increased scrap rate, and achieve the effect of ensuring smooth operation, preventing friction and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

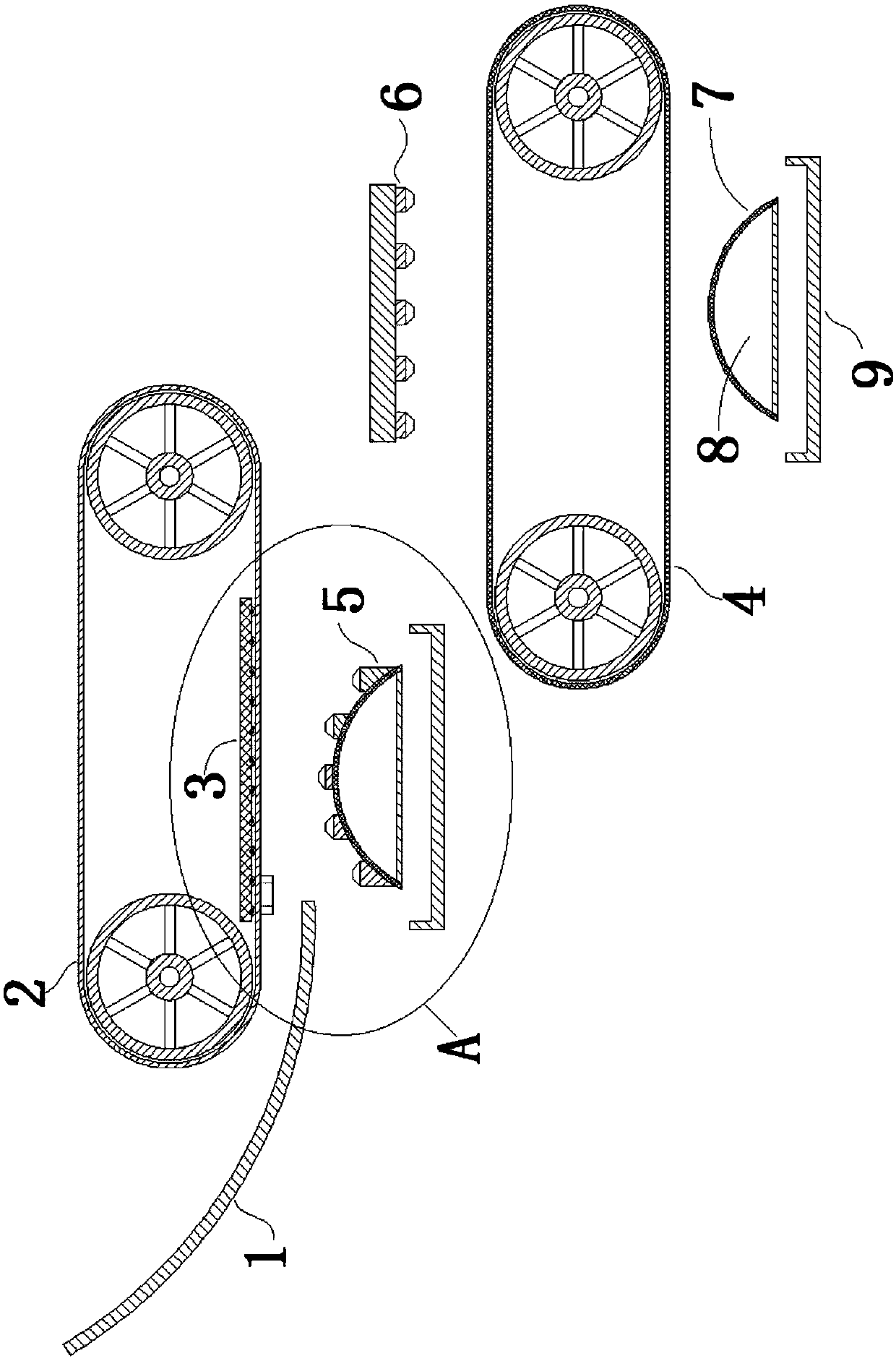

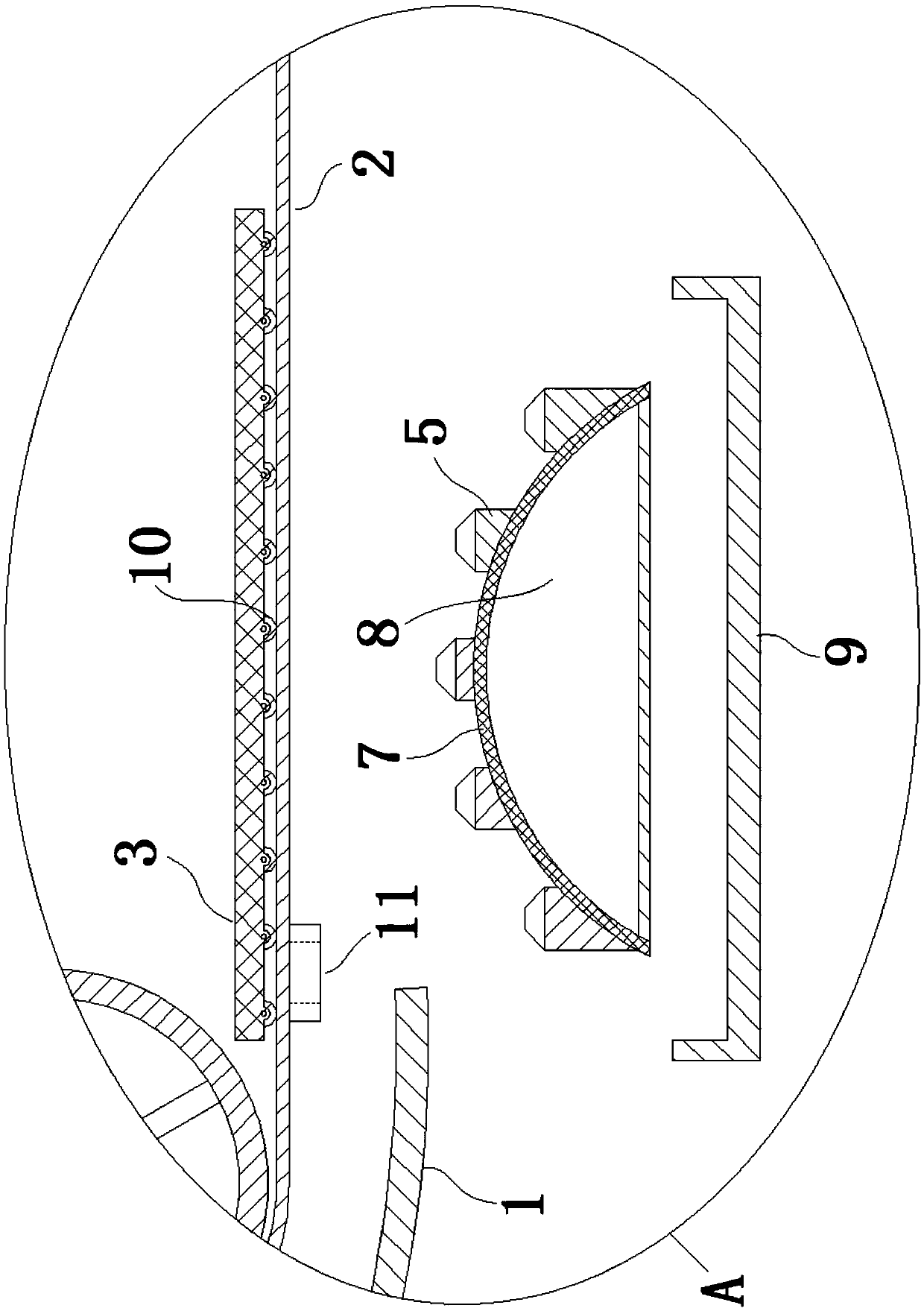

[0024] The device of the present invention comprises a first conveying base plate 1, a first conveying belt 2 and a second conveying belt 4; an impurity filtering sieve plate 7 for recovering washing liquid; an impurity collecting tank plate 9 for collecting impurities; the inner side of the first conveying belt 2 An adsorption electromagnetic plate device 3 is provided; a first cleaning nozzle device 5 is provided below the first conveyor belt 2 ; a second cleaning nozzle device 6 is provided above the second conveyor belt 4 .

[0025] The cross section of the first transmission substrate 1 is an arc-shaped structure; the end side of the first transmission substrate 1 is located below the first conveyor belt 2; the position of the end side of the first transmission substrate 1 matches the position of one end side of the adsorption electromagnetic plate device 3 .

[0026] The adsorption electromagnetic plate device 3 is equipped with a plurality of fixed-slip guide wheels 10 ...

specific Embodiment 2

[0030] Carry out the cleaning operation on a batch of bearing workpieces with the same degree of pollution, and carry out corresponding tests on the cleaning operations using the traditional cleaning method and the device of the present invention.

[0031] Table 1: Use traditional cleaning methods for cleaning.

[0032] Bearing diameter / mm

[0033] Table 2: Cleaning operation using the device of the present invention.

[0034] Bearing diameter / mm

[0035] It can be seen from the above two tables that the efficiency of cleaning the bearing workpiece by the device of the present invention is significantly better than that of the traditional cleaning method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com