Quick-clamped PCB gluing device

A technology of PCB board and gluing device, which is applied to the device and coating of surface coating liquid, which can solve the problems of inability to meet the coating requirements of PCB board, short circuit of circuit, high equipment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

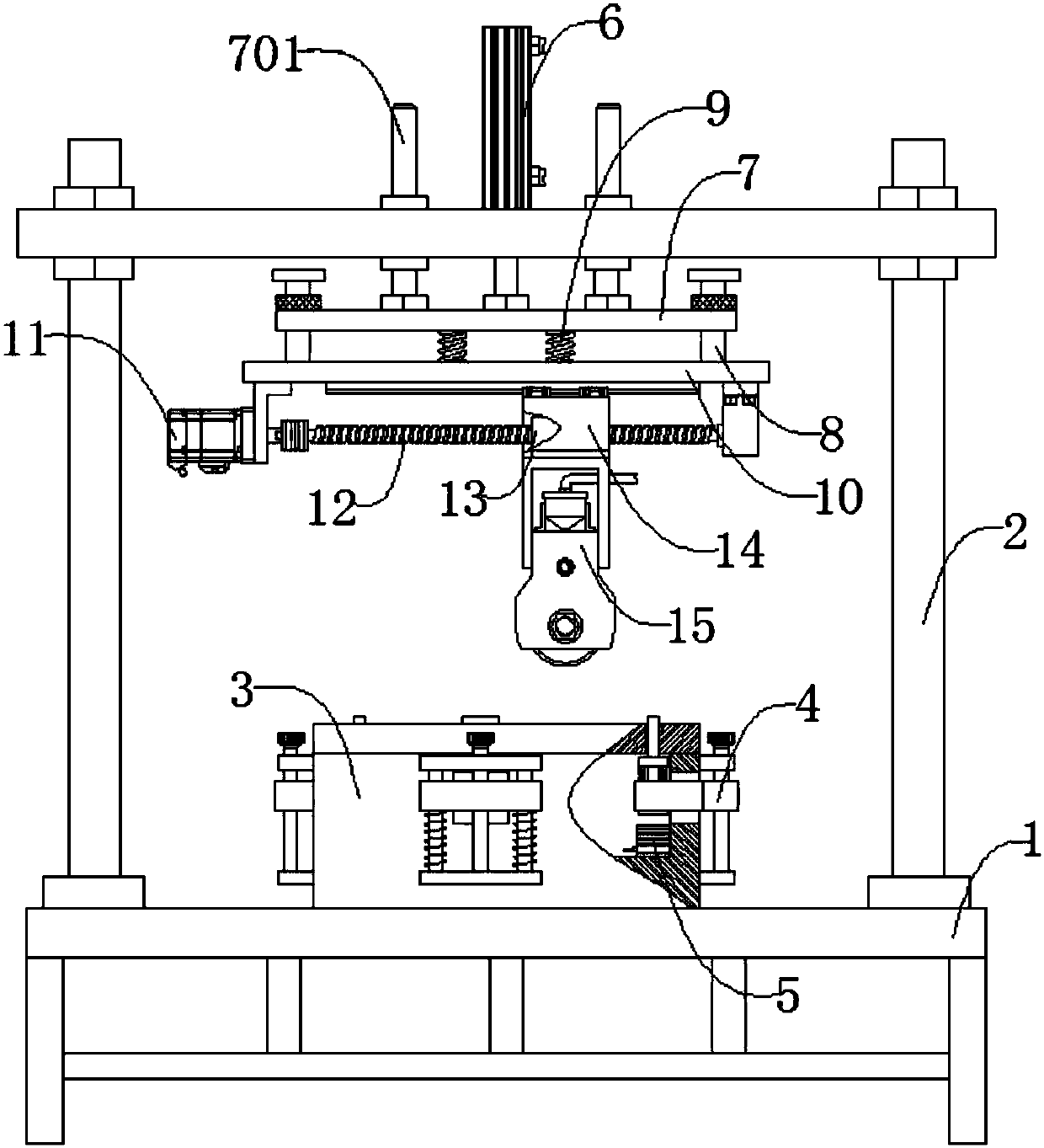

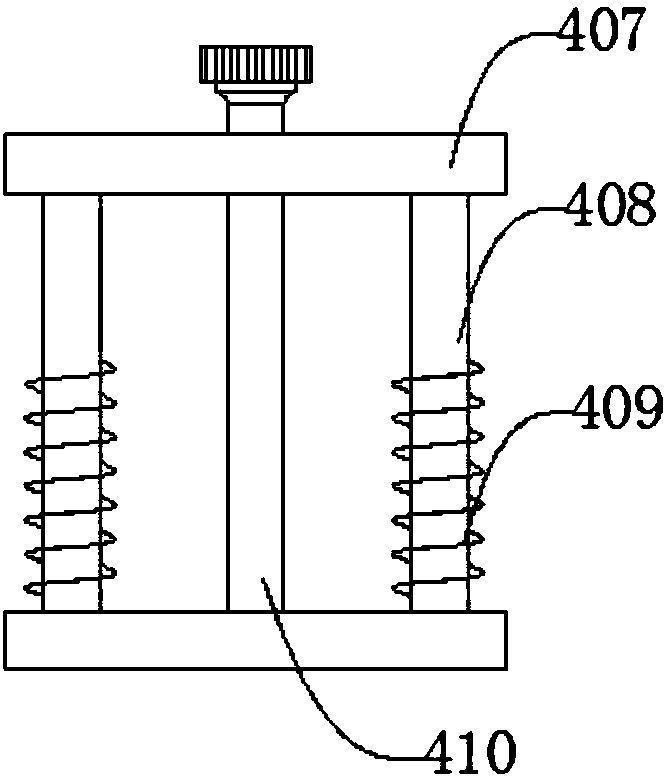

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6As shown, a quick clamping PCB board gluing device includes a frame 1, a door frame 2, a fixture seat 3, a positioning mechanism 4, an electromagnet 5, a cylinder 6, an upper push plate 7, a connecting rod 8, a first Spring 9, lower push plate 10, servo motor 11, leading screw 12, feed nut 13, slide seat 14, gluing mechanism 15, described portal frame 2 is positioned at frame 1 upper end, and described portal frame 2 and machine The frame 1 is connected by welding, the clamp seat 3 is located at the upper end of the frame 1, the clamp seat 3 is connected with the frame 1 by bolts, the clamp seat 3 is also provided with a positioning mechanism 4, and the positioning mechanism 4 Connected with the fixture seat 3 by bolts, the electromagnet 5 is located inside the fixture seat 3, the electromagnet 5 is connected with the fixture seat 3 by bolts, the cylinder 6 is located at the upper end of the doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com