Method for evaluating the tendency of anisotropic metals and alloys to crack

An alloy material, anisotropic technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problem of inability to evaluate the axial cracking tendency of small-sized plates, rods, and wires of anisotropic metal and alloy materials, etc. problem, achieve the effect of reducing the risk of batch sampling and inspecting a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

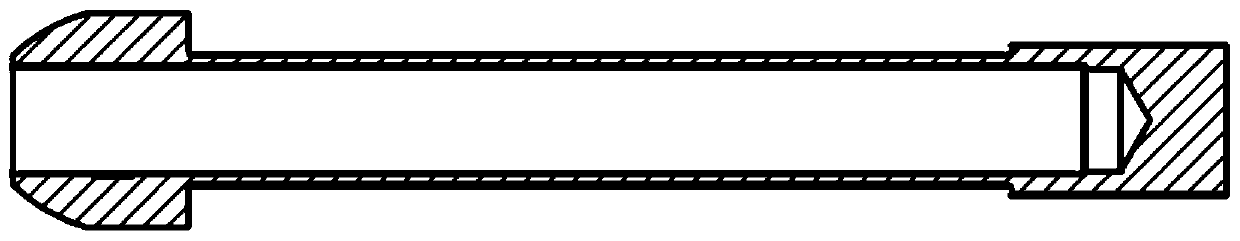

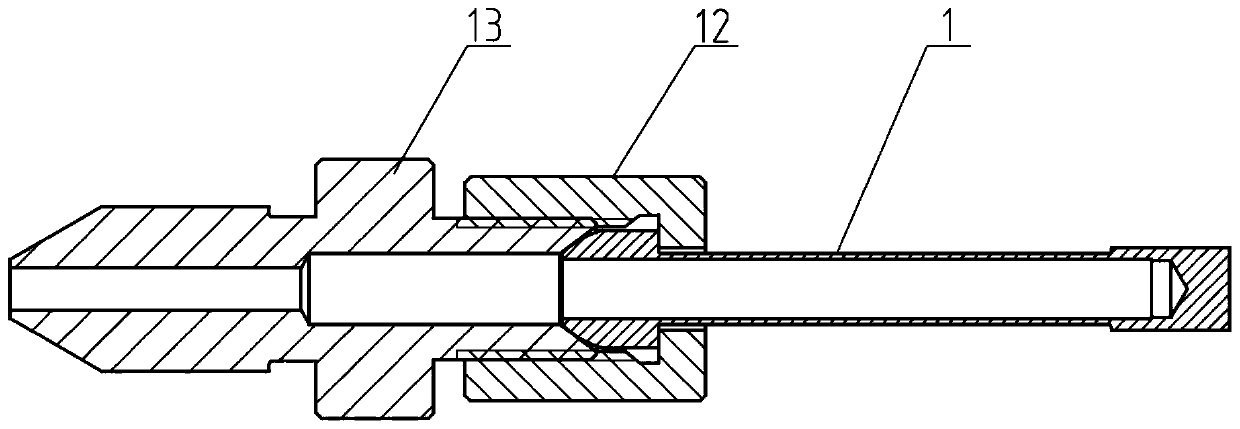

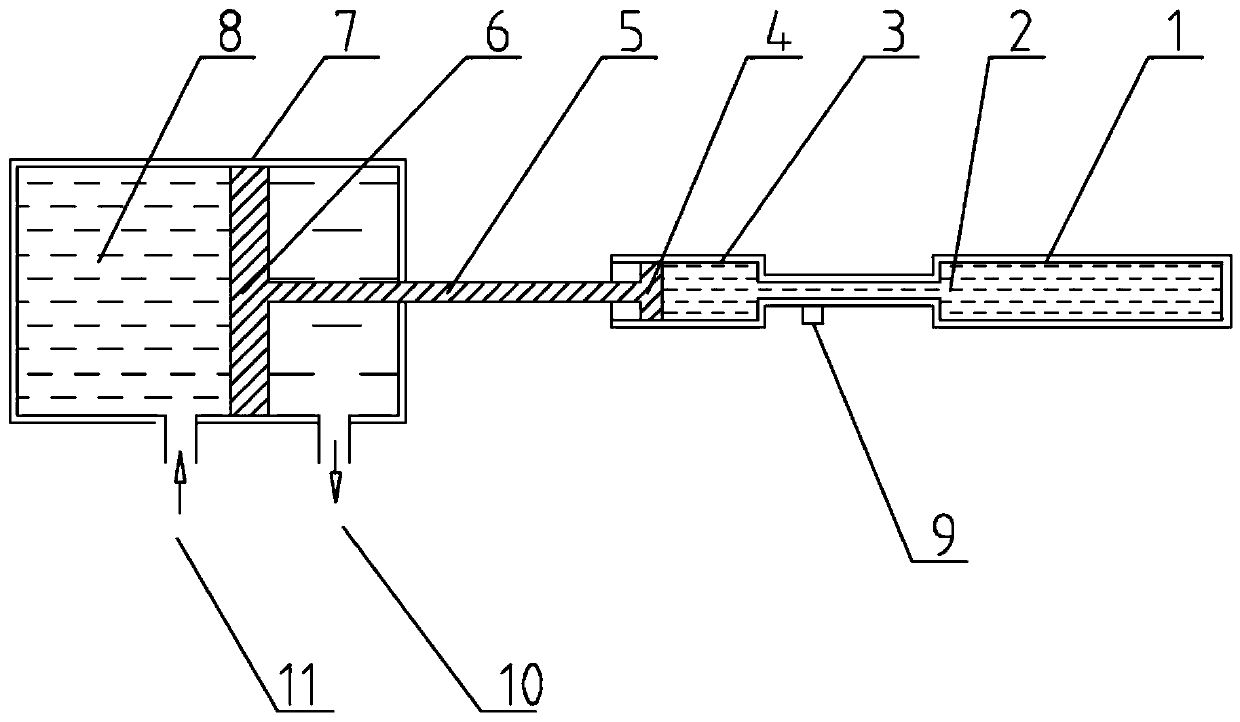

[0057] The invention proposes a method for evaluating the cracking tendency of the metal and alloy structural materials along the material axis with the breaking strength between 300 and 2200 MPa. The test system used in the present invention is a hydraulic burst test system.

[0058] The specific process is as follows:

[0059] Step 1, making of sample:

[0060] For the raw materials of rods and wires, use a grinding wheel cutter to cut a section of φ10mm rod with a length of 100mm to obtain a cylinder of this material. The grinding wheel cutting machine is Bosch brand TCO2100.

[0061] For the raw material of the plate, a section of the material cylinder is obtained by cutting with a wire electric discharge machine. The electric spark cutting machine selects the Dk77 series CNC fast wire cutting machine of Suzhou Electric Machine Tool Research Institute.

[0062] The axis of rotation of the cylinder coincides with the direction of grain flow of the material being evaluat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com