Well completion production pipe string capable of mining at lower part and injecting at upper part and with electric submersible pump

A production pipe string and submersible electric pump technology is applied in the field of lower production, upper injection and completion production pipe string, which can solve the problems of inability to meet oil reservoir requirements, high development difficulty and high investment cost, and achieves shortening operation time and lower operation cost. , the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

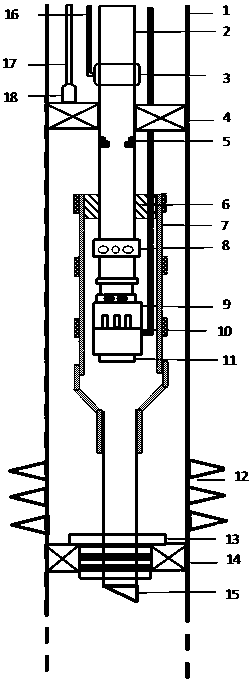

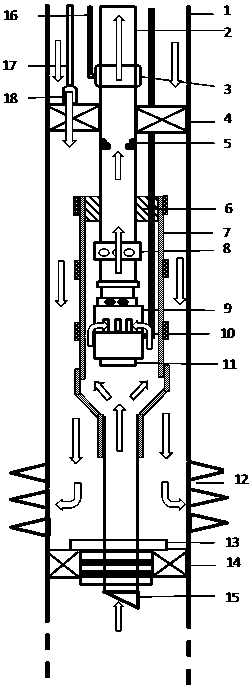

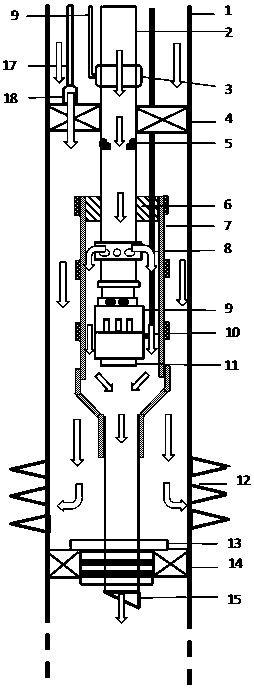

[0018] Such as figure 1 As shown, the present invention has a lower production and upper injection well completion production string with an electric submersible pump, including a casing 1 for a lower production and upper injection well, an oil pipe 2 arranged in the casing 1, and an oil pipe 2 arranged on the oil pipe 2. Downhole tools.

[0019] The downhole tool includes a downhole safety valve 3 connected to a hydraulic control line 16 arranged on the upper part of the tubing and a casing layered packer 14 with a sealing cylinder arranged at the bottom of the tubing; the casing layered sealer The spacer 14 is matched with a positioning seal 13 . Between the downhole safety valve 3 and the positioning seal 13 are sequentially connected a cable production packer 4 with an air release valve 18, a work cylinder 5 and a closed electric submersible pump system from top to bottom; the air release valve 18 is provided with There is a hydraulic control pipeline 17 for the air rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com