Thermomechanical treatment strengthening process of cu-ni-be alloy

A thermomechanical treatment, cu-ni-be technology, applied in the strengthening process of high-conductivity and high-strength copper alloys, can solve the problems of long process, complicated process, and increased production costs, so as to simplify the process steps and strengthen the process , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A Cu-Ni-Be alloy thermomechanical treatment strengthening process specifically comprises the following steps:

[0034] Step 100: heating the Cu-Ni-Be alloy ingot to 960-980°C at a heating rate of 10°C / min, and then keeping the temperature for 60-180min;

[0035] Step 200: Perform 30-60% hot extrusion on the cast ingot processed in step 100 at a speed of 0.05-1 m / s, and then water-cool the billet after hot extrusion. The water temperature does not exceed 30°C;

[0036] Step 300: Perform aging treatment at 470° C. for 3 hours on the billet treated in step 200, and then air-cool.

Embodiment 2

[0038] A Cu-Ni-Be alloy thermomechanical treatment strengthening process specifically comprises the following steps:

[0039] Step 100: Hot forging the Cu-Ni-Be alloy ingot to form a round or square forging billet, then heating the forging billet to 960-980°C at a heating rate of 10°C / min, and then keeping it warm for 60-180min ;

[0040] Step 200: Perform 30-60% hot extrusion or hot-press forming on the forged billet processed in step 100 at a hot-extrusion speed or hot-press speed of 0.05-1m / s, then water-cool, hot-extrude or hot-press the billet The temperature of the ingot entering water is not less than 950°C, and the cooling water temperature of the circulating water is not more than 30°C;

[0041] Step 300: Perform aging treatment at 470° C. for 3 hours on the billet treated in step 200, and then air-cool.

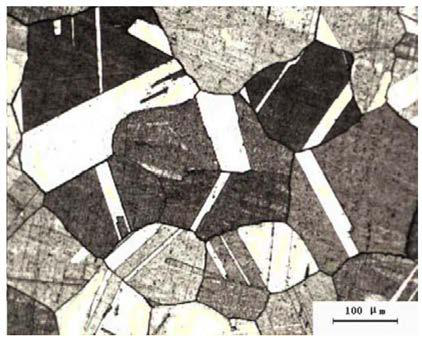

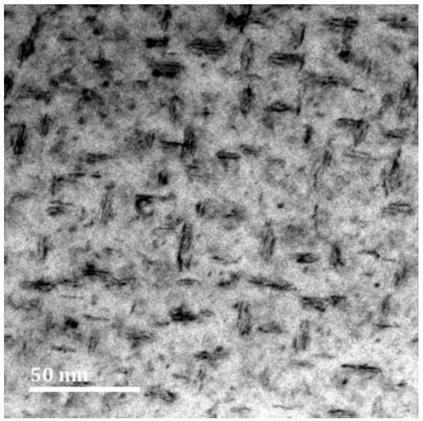

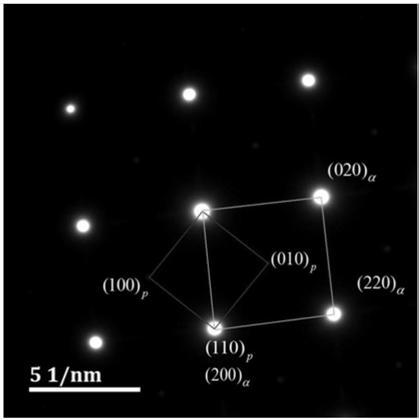

[0042] In Examples 1 and 2, the raw material Cu-Ni-Be alloy ingot, the composition is Ni 1.9wt%, Be 0.38wt%, impurity is not more than 0.1wt%, balance Cu, Ni is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com