Servo feeding system reliability testing device and method

A technology of servo feed and test device, applied in general control system, control/adjustment system, test/monitoring control system, etc., can solve the problem of not having double screw of analog CNC machine tool, etc., to achieve convenient operation and detection, detection Reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in detail below in conjunction with accompanying drawing:

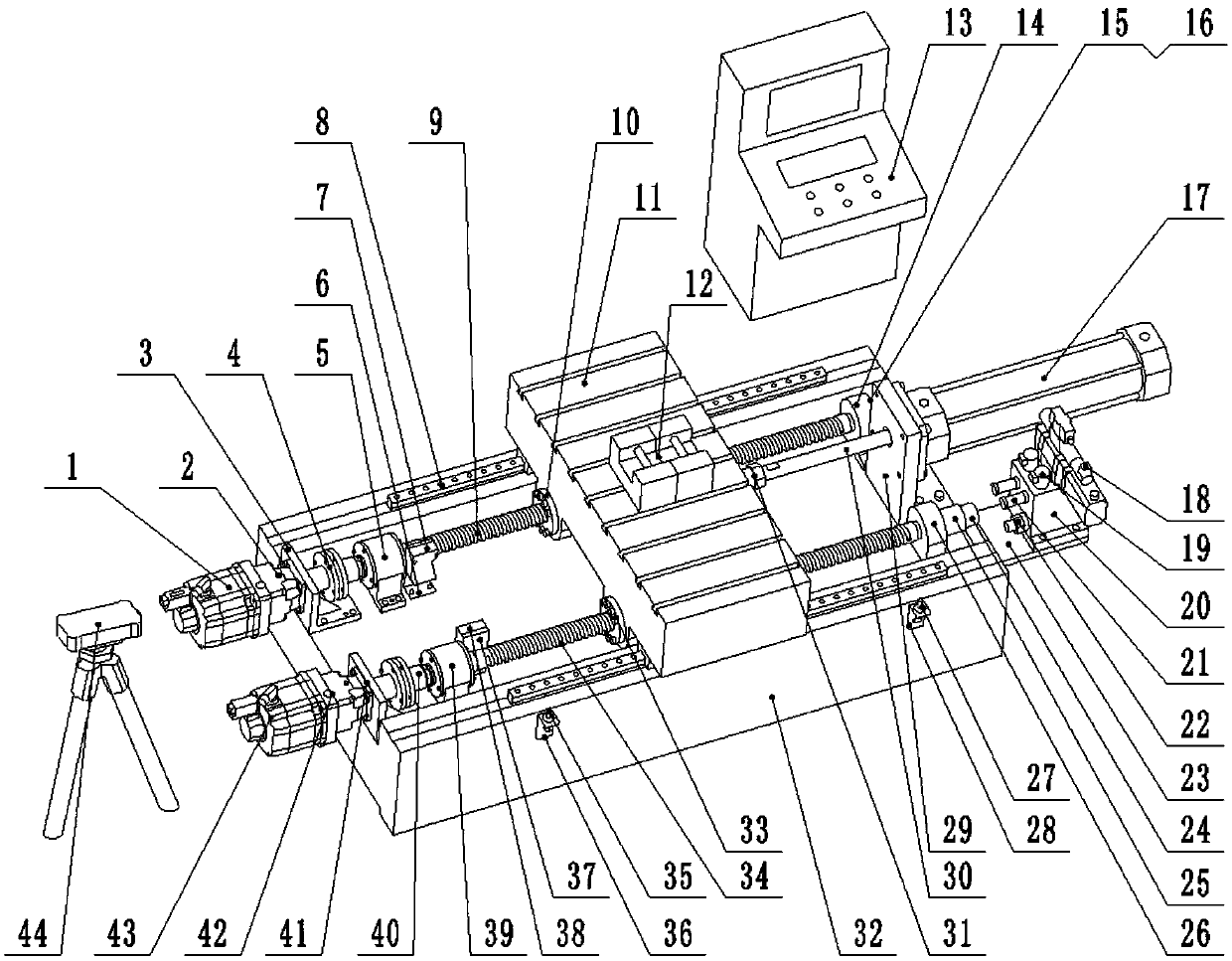

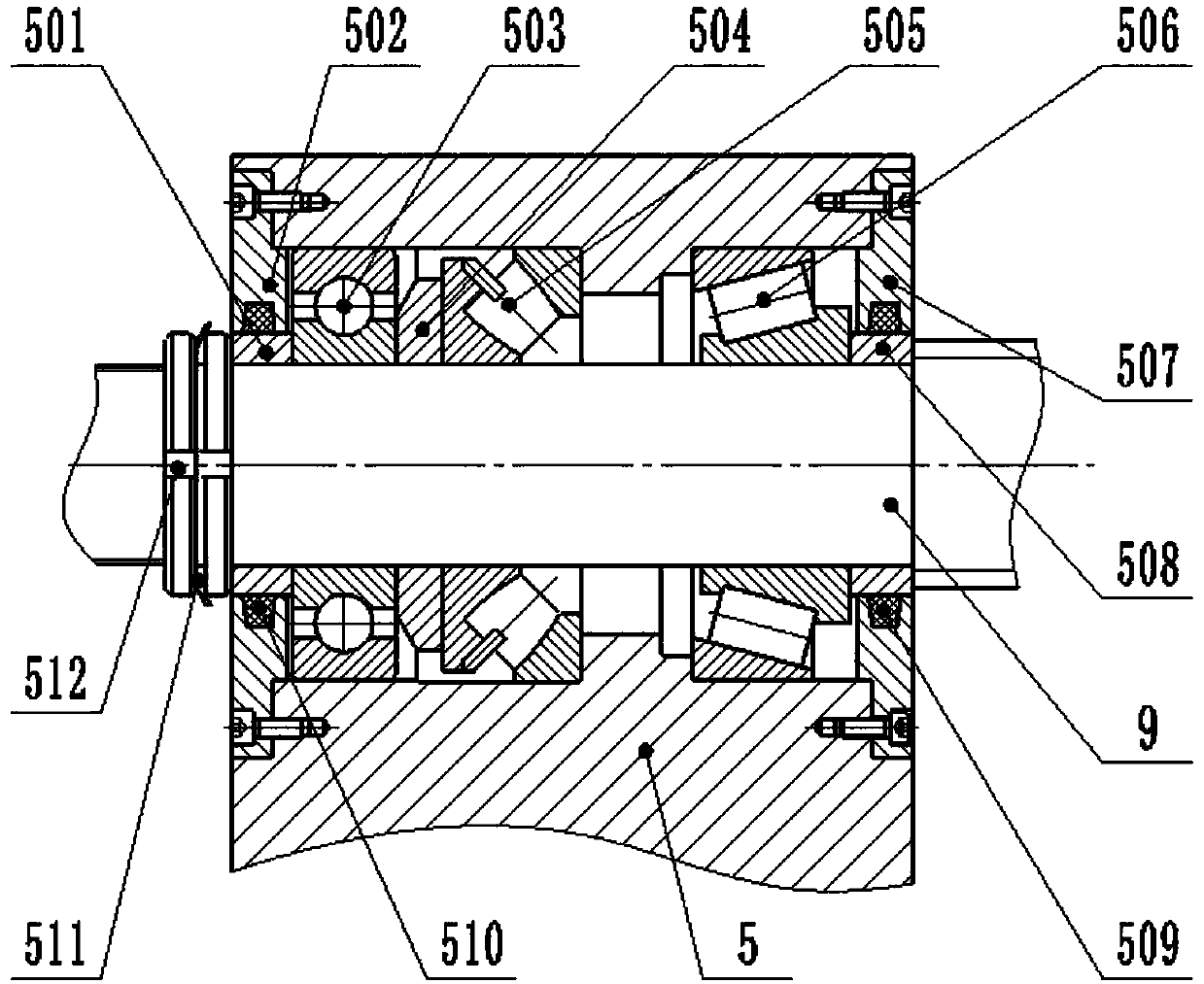

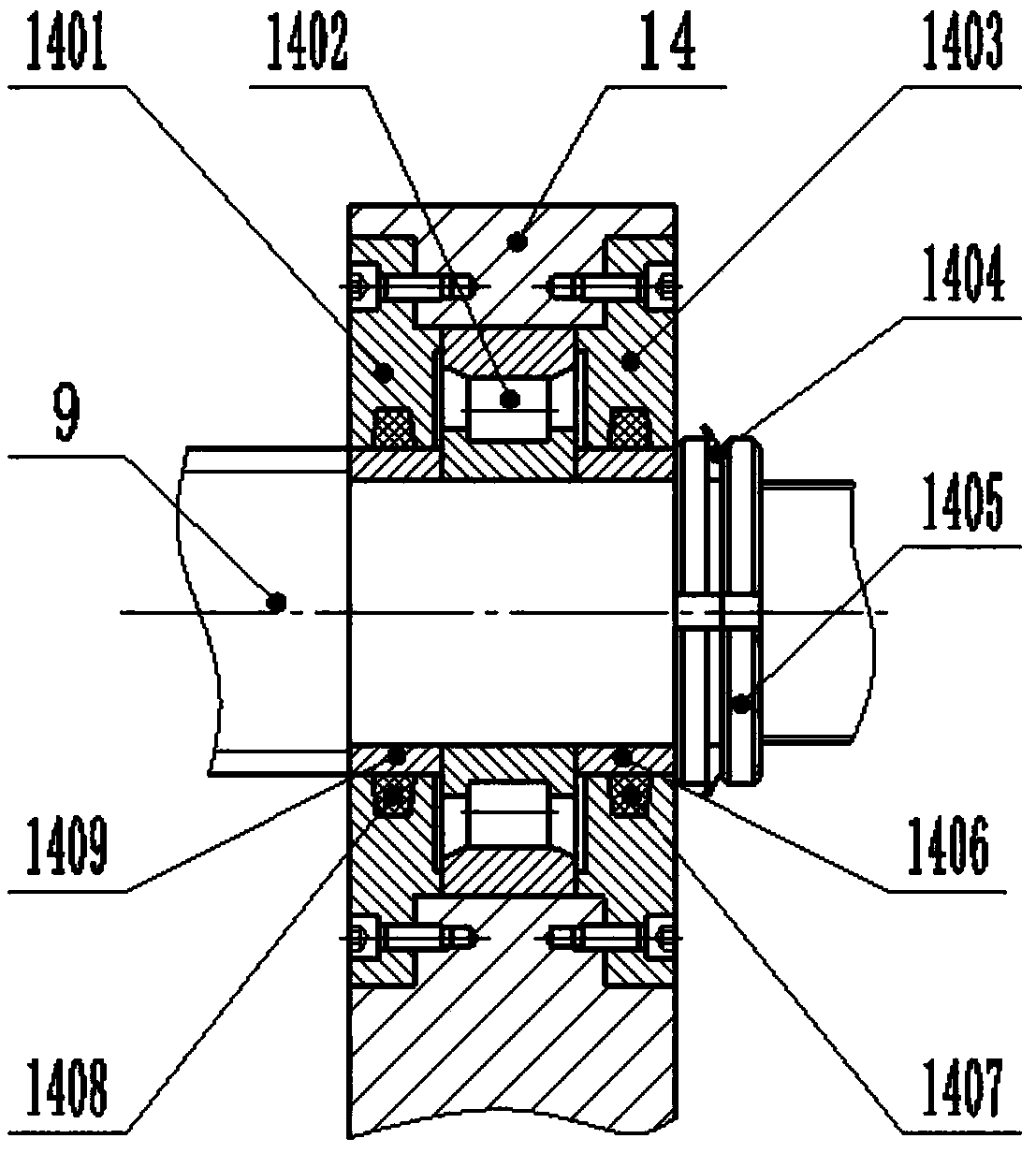

[0050] The present invention simulates the different working conditions of the double-screw synchronous drive servo feed system in actual operation, and obtains the reliability and accuracy reliability data of the double-screw synchronous drive servo feed system under different load conditions, and at the same time A complete set of reliability test methods for the dual-screw synchronous drive servo feed system is proposed.

[0051] The double-screw synchronously driven servo feed system reliability test device and test method of the present invention are mainly composed of two parts, namely the double-screw synchronously driven servo feed system reliability test device and the double-screw synchronously driven The reliability test method of the servo feed system reliability test device.

[0052] 1. Double screw synchronous drive servo feed system reliability test device

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com