Three-phase thyristor power regulator

A power regulator and thyristor technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as inability to be connected and parallel, high energy consumption of cooling system, unstable control, etc., and achieve response speed. Fast, small size, to achieve the effect of precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

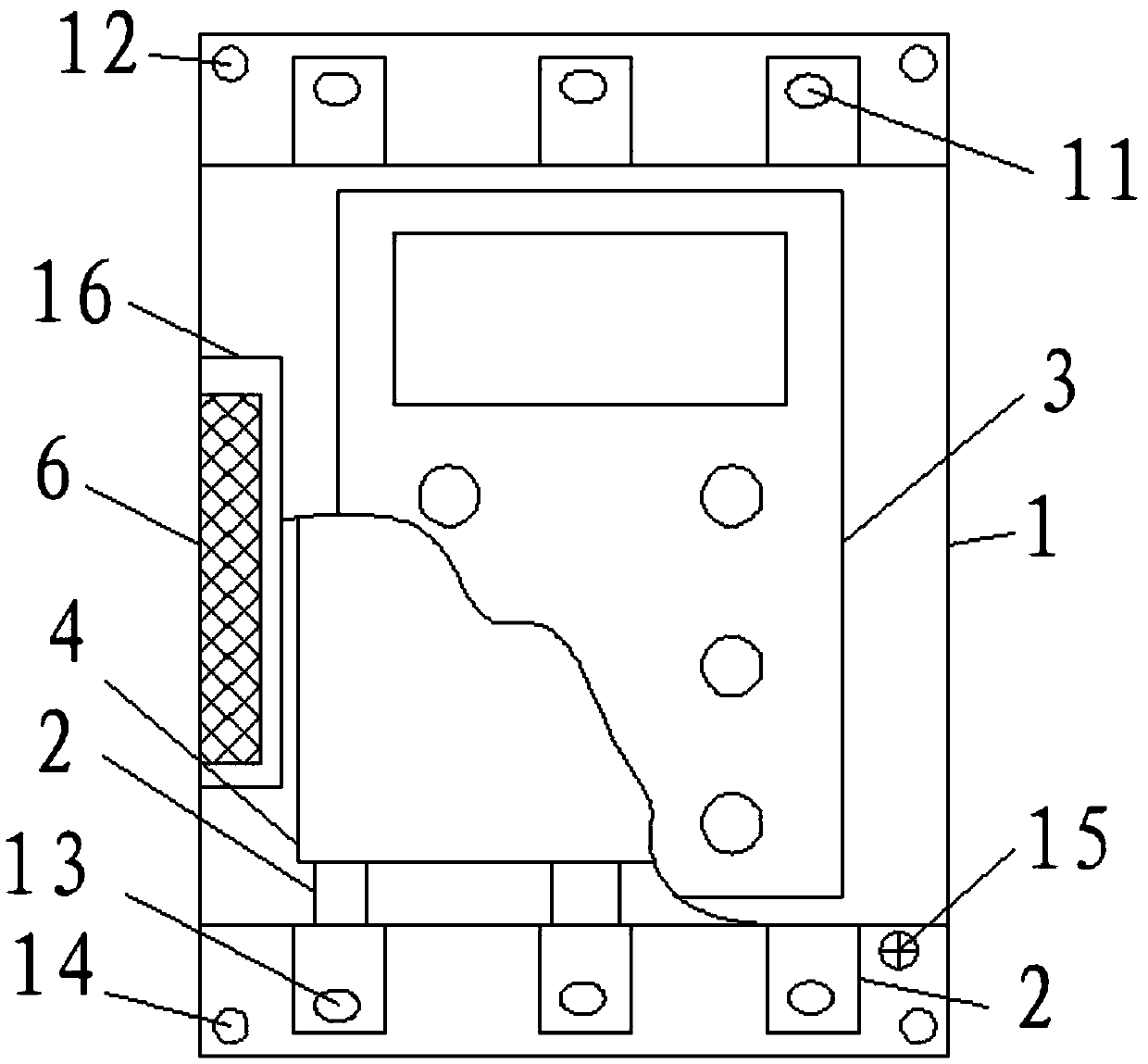

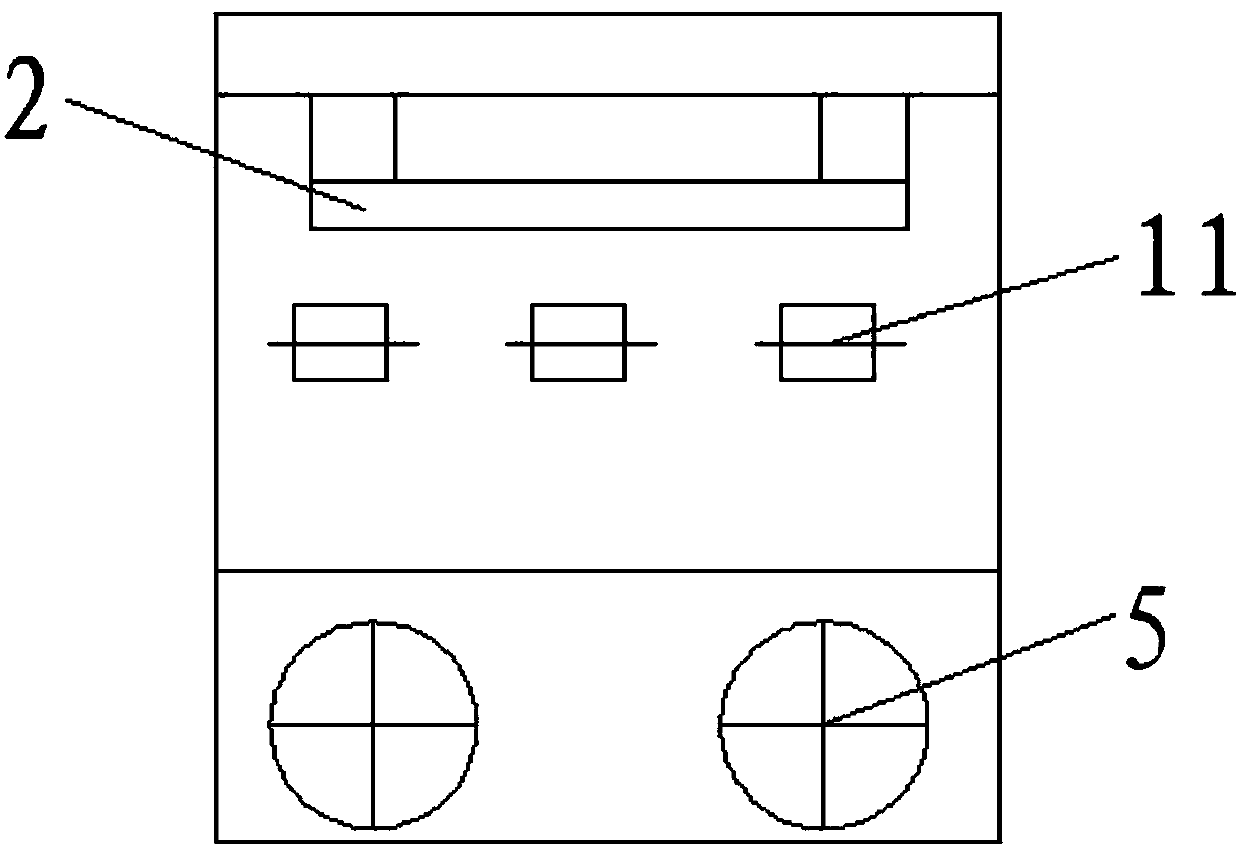

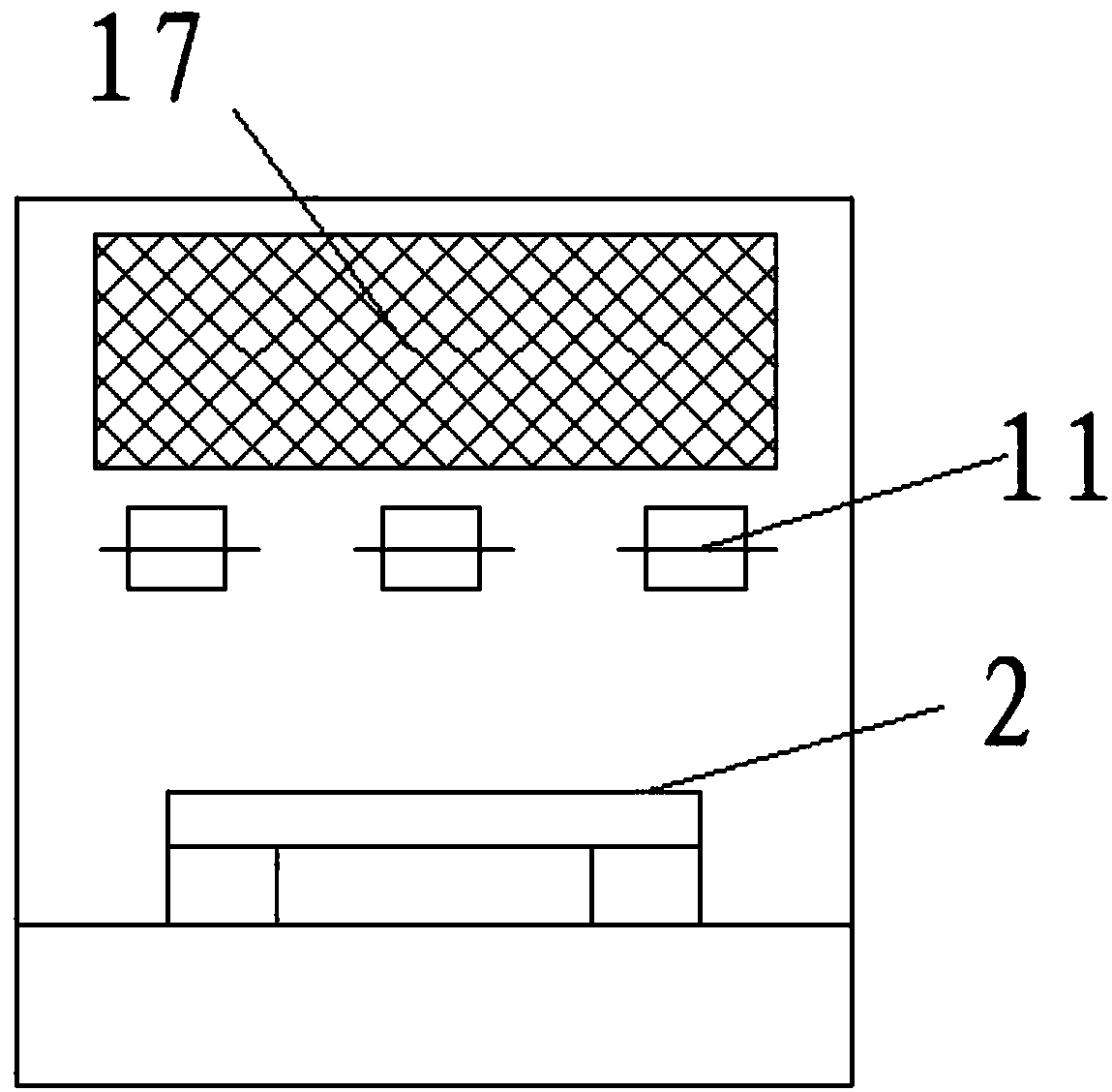

[0023] As shown in the figure: Three-phase thyristor power regulator, which includes outer casing 1, copper bar 2, display operation panel 3, circuit board 4, centrifugal fan 5 and control terminal 6, copper bars are welded and installed in the casing 1 2 and the circuit board 4, the middle part of the panel of the casing 1 is screwed and installed with a display operation panel 3, the top side of the panel is provided with an upper terminal 11 and the first installation hole 12, and the bottom side of the panel is provided with a lower The terminal 13, the second mounting hole 14 and the grounding screw 15, the side of the panel is provided with a groove 16, the control terminal 6 is installed in the groove 16, the centrifugal fan 5 is installed at the bottom, and the cooling hole 17 is opened at the top .

[0024] A PLC control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com