Battery collecting device and monitoring method

A collection device and battery technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as increasing SOC error, false triggering of fault alarms, abnormal execution of battery management system strategies, etc., to achieve simple and effective reset, reduce abnormal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

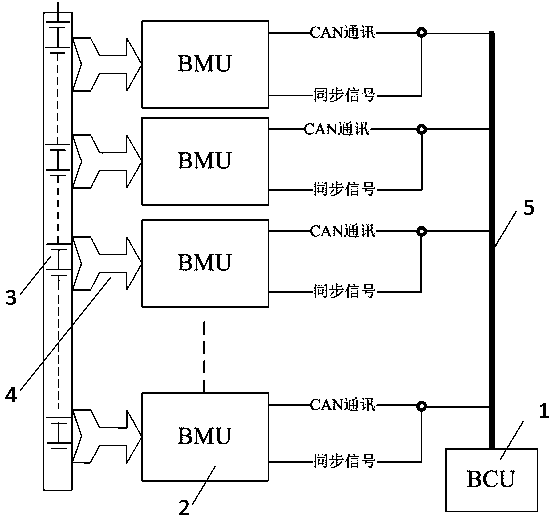

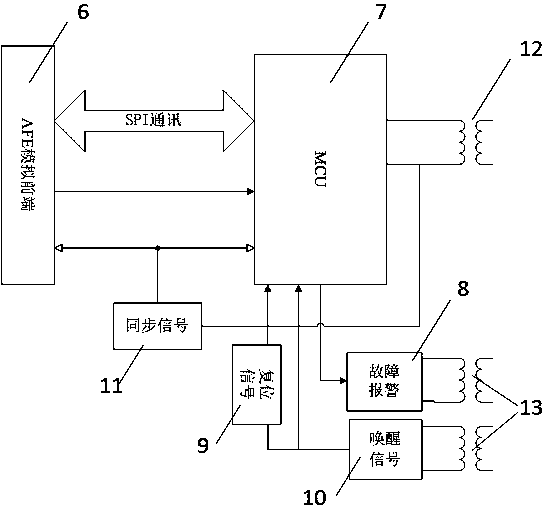

[0031] Such as Figure 1-2 As shown, a battery status acquisition device of the present invention is provided, including BCU1, BMU2 and battery module 3; the battery module 3 is connected to the BCU1 through the acquisition wire harness 4; the BMU2 is connected to the BCU1 through the CAN bus 5 ; The BMU2 includes AFE 6, MCU7, fault alarm unit 8, reset module 9, wake-up unit 10 and synchronization signal trigger unit 11.

[0032] Further, the number of BMU2 is greater than or equal to 1.

[0033] Further, it also includes a first isolator 12 and a second isolator 13;

[0034] The CAN signals all pass through the first isolator 12 or the second isolator 13;

[0035] The first isolator 12 is a high-speed isolator;

[0036] The second isolator 13 is a passive isolator.

[0037] Further, the AFE is connected to the M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com