Rectifying and noise lowering exhaust hood

A technology of a range hood and a fairing, which is applied in the field of range hoods, can solve the problems of high cost and complicated manufacturing process, and achieve the effects of low cost, noise reduction and smooth airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

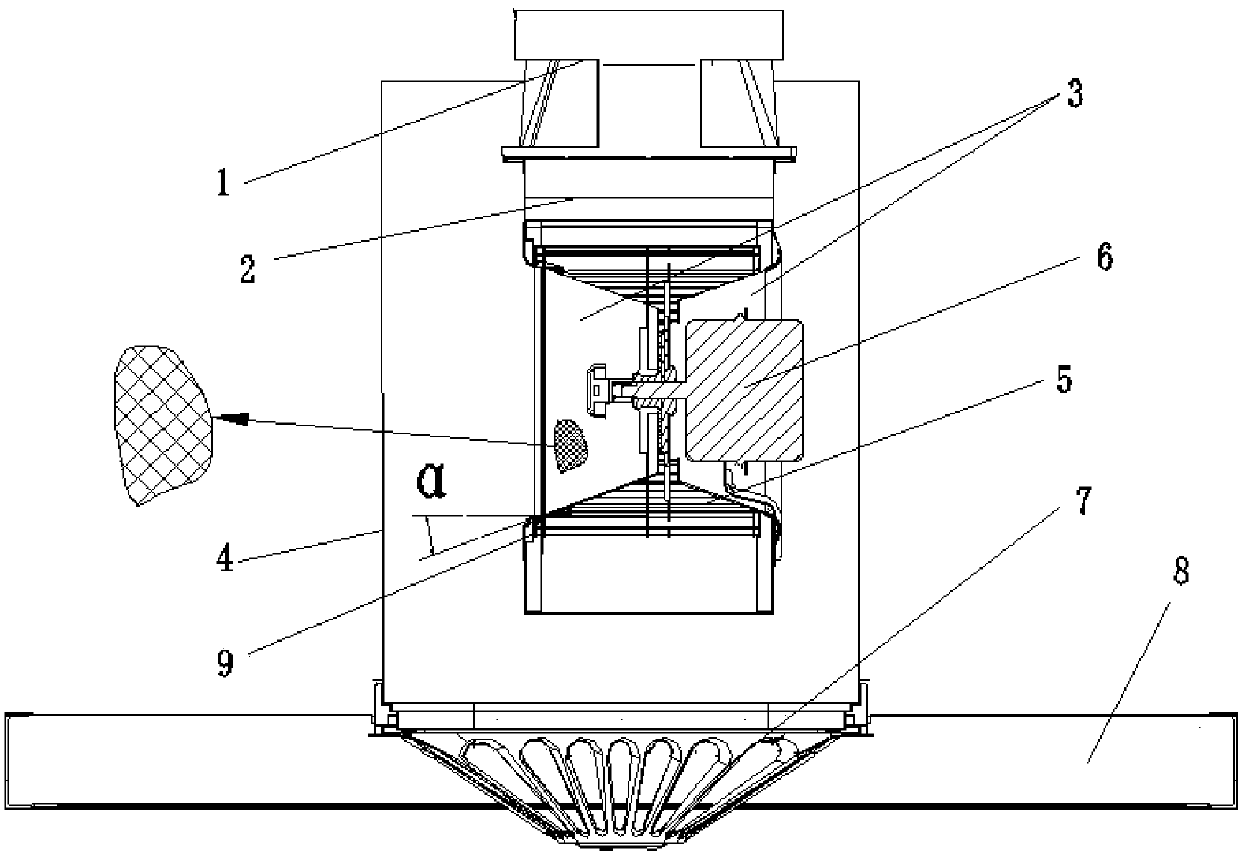

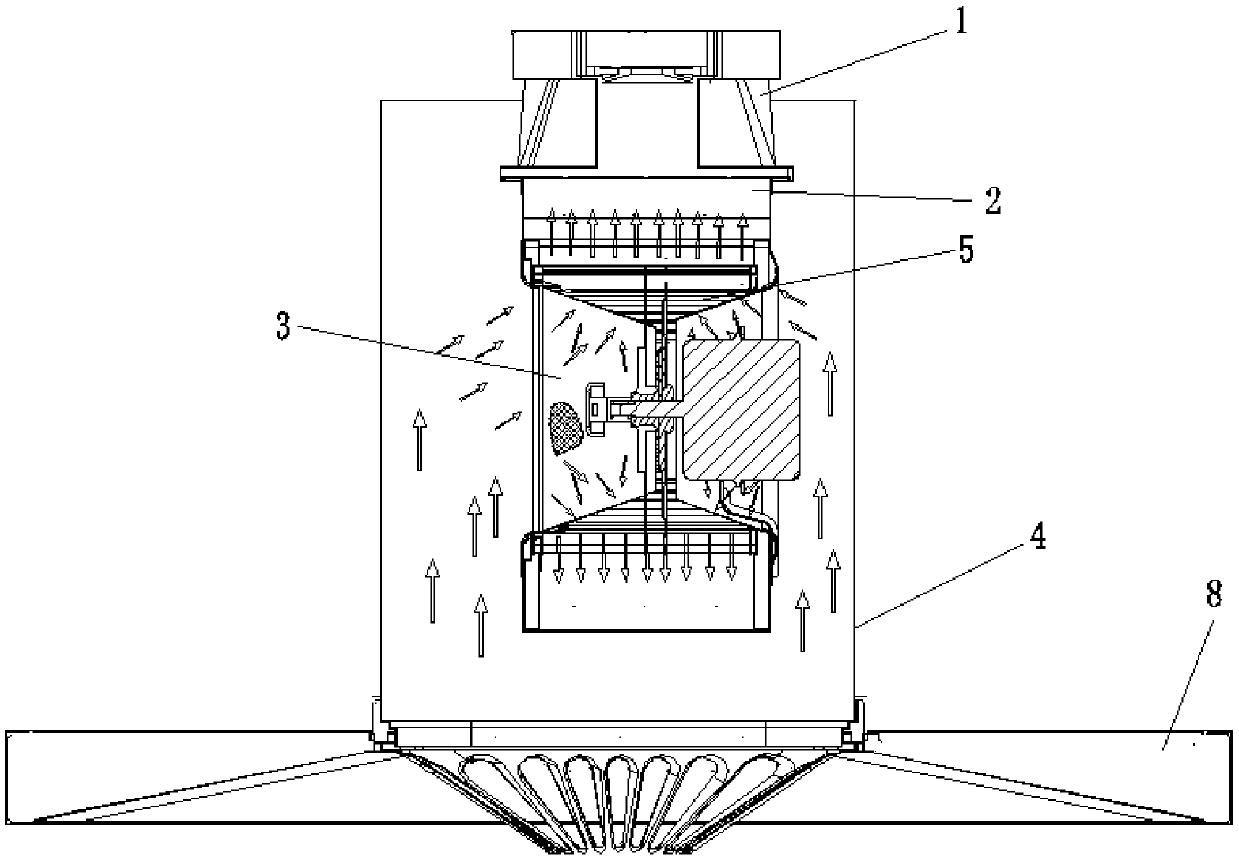

[0029] Embodiment 1: This rectifying and noise-reducing range hood mainly includes a check valve 1, an air duct 2, a housing assembly 4, an oil screen 7 and a smoke collection hood 8, and the oil screen 7 is located at the center of the smoke collection hood 8. The upper part of the smoke collecting hood 8 and the oil screen 7 is connected with the shell assembly 4, the air duct 2 is located in the shell assembly 4, the top of the air duct 2 is provided with a check valve 1, the air duct 2 is provided with an impeller 5 and a motor 6, and the impeller The two sides of 5 are provided with air inlet ring 9, and the air inlets on both sides of the inside of air duct 2 are provided with fairing 3, and the motor adopts an inner rotor motor, which is convenient for the assembly of fairing, and the motor shaft is fixedly connected with the wheel disc of the impeller , the fairing extends close to the wheel disc to achieve a more comprehensive fairing effect.

[0030] When the hood is...

Embodiment 2

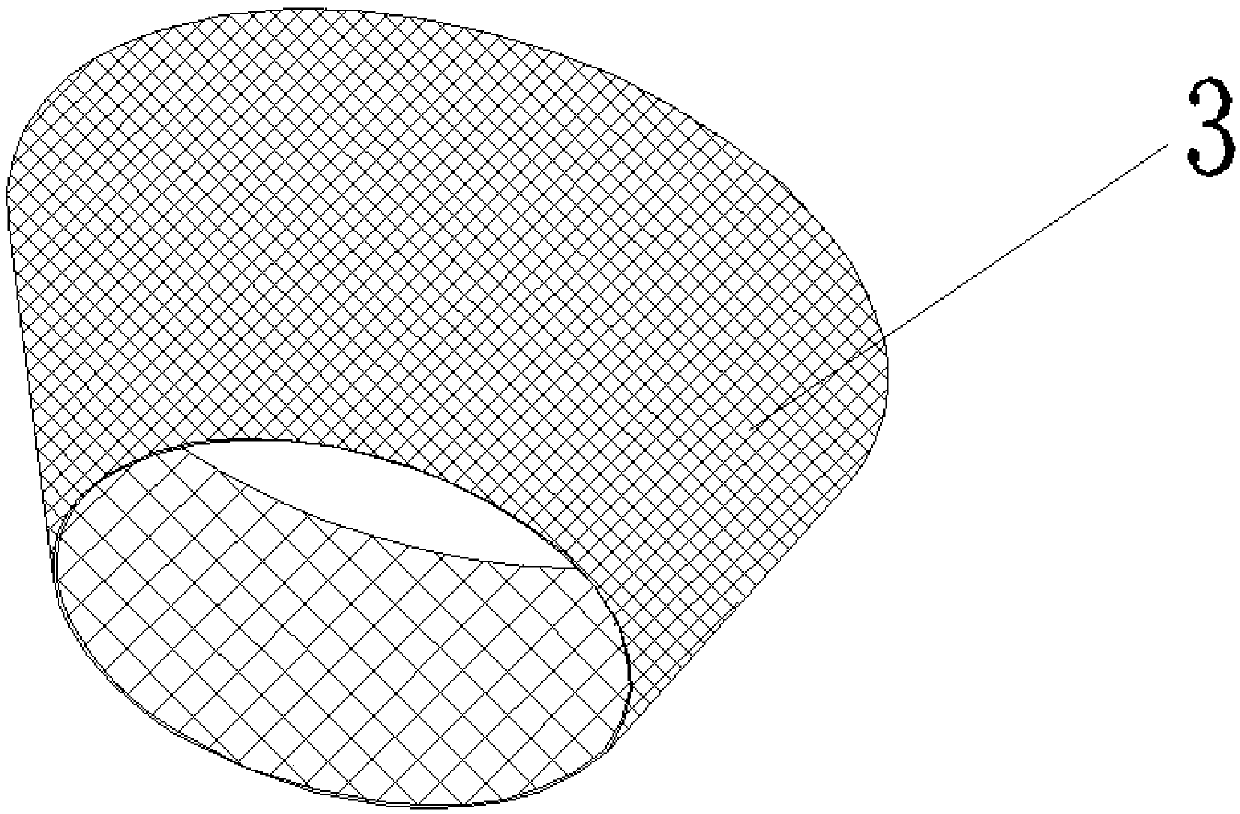

[0031] Embodiment 2: On the basis of Embodiment 1, the fairing 3 and the air inlet ring 9 are integrally installed on the front panel or the rear panel of the air duct 2 or separately. The fairing 3 is located inside the air duct 2, and covers the front end of the air inlet of the impeller 5, which can protect the impeller, avoid damage to the impeller 5 by flames, foreign objects, oil stains, etc., improve the life of the hood, and keep the impeller 5 clean.

Embodiment 3

[0032] Embodiment 3: On the basis of Embodiment 2, the fairing 3 is conical or cylindrical, and the structure is gradually closed from the outside to the inside. The angle α between the section of the fairing 3 and the axial direction of the motor 6 is 0-60 To rectify and guide the airflow between degrees, the fairing 3 is in the form of holes on both sides or openings on one side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com