Normally-closed proportional one-way flow valve

A flow valve and proportional technology, which is applied in the field of normally closed proportional one-way flow valve, can solve the problems of rising use cost and large volume of hydraulic valve group, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

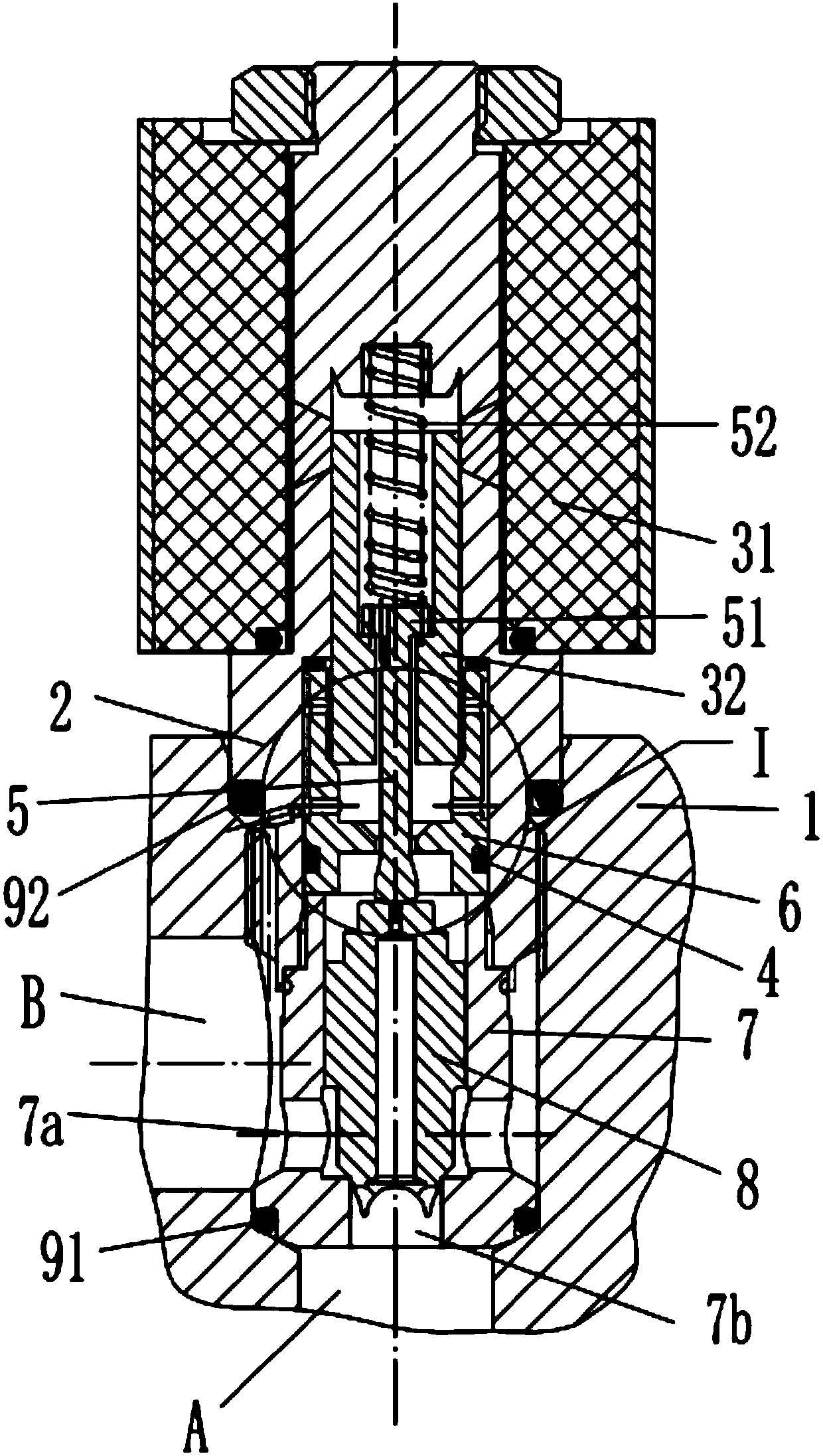

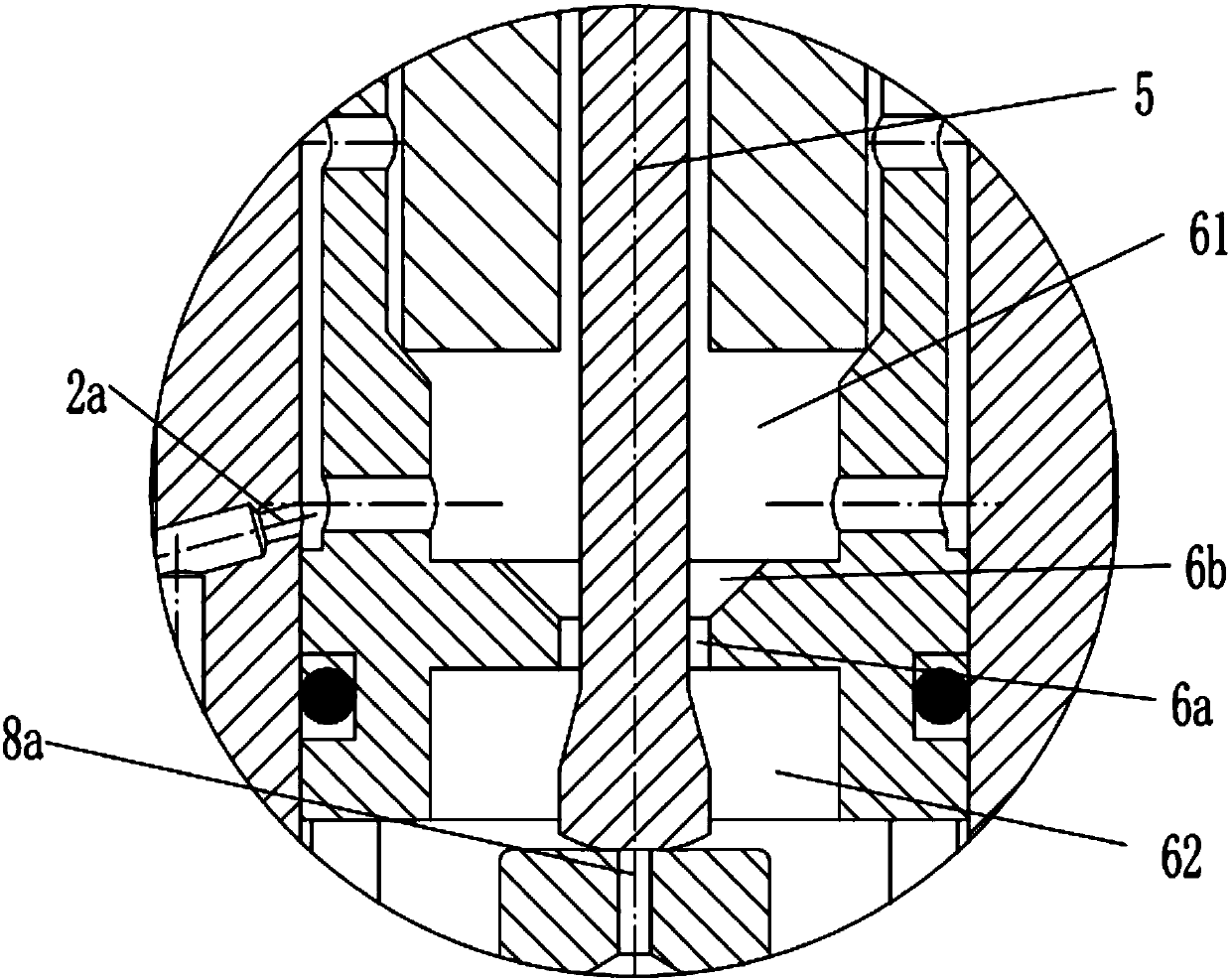

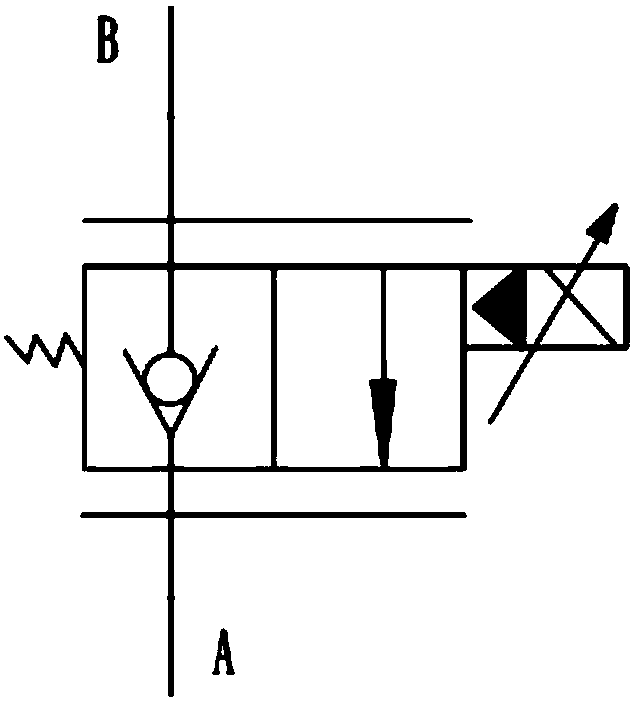

[0018] Such as Figure 1 to Figure 3 Shown is the structural representation of the present invention,

[0019] The reference signs are: A port, B port, valve body 1, screw sleeve 2, first damping hole 2a, proportional electromagnet 31, armature 32, pilot valve core 5, protruding ring 51, spring 52, positioning sleeve 6 , throttle hole 6a, tapered hole 6b, pressure feedback chamber 61, hydraulic control chamber 62, valve sleeve 7, side oil hole 7a, lower oil hole 7b, main valve core 8, second damping hole 8a, first sealing ring 91 , The second sealing ring 92.

[0020] Such as Figure 1 to Figure 3 as shown,

[0021] A normally closed proportional one-way flow valve, including a valve body 1, which is provided with A port and B port, the upper part of the valve body 1 is screwed with a screw sleeve 2, and the upper part of the screw sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com