Mobile steel pipe inner diaphragm installation complete device, installation system and construction method thereof

A complete set of device and inner partition technology, applied in the field of steel structure manufacturing, can solve the problems of high labor consumption, low efficiency and low precision, and achieve the effects of labor saving, simple manufacturing and high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

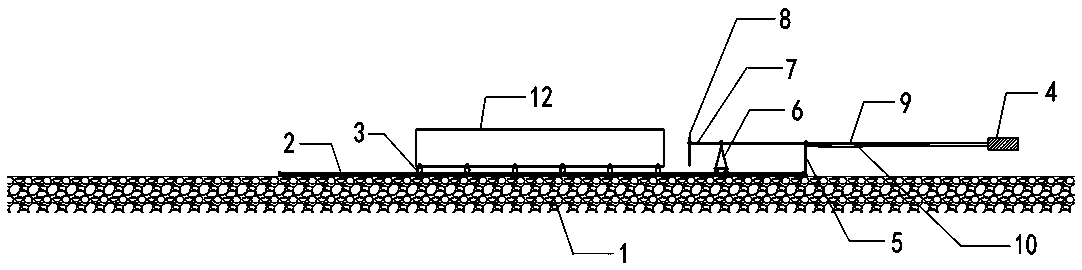

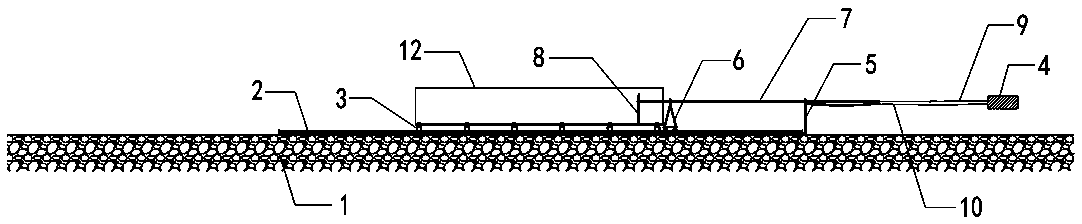

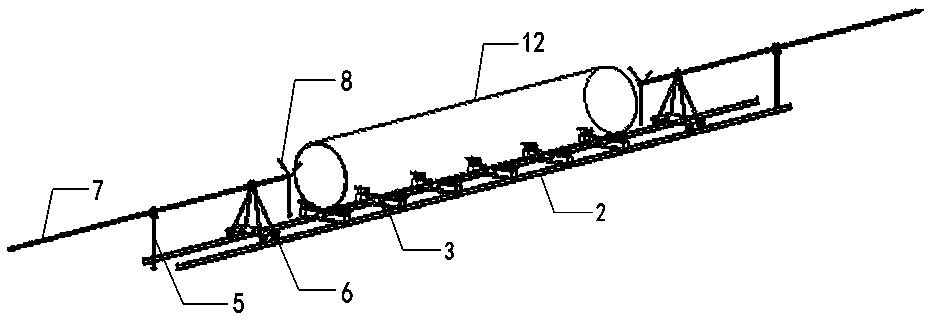

[0076] Examples see Figure 6 and Figure 7 As shown, the mobile steel pipe inner partition installation complete set of equipment, installation system and construction method,

[0077] The complete set of mobile steel pipe inner partition installation includes a foundation 1, a pair of rails 2 arranged in parallel on the foundation 1, and a row of tires arranged at even intervals between the pair of rails 2 along the length direction of the rails 2. Frame 3, a mobile system arranged on at least one side of a row of tire frames 3 and a traction device 4 connected to the end of the mobile system through a traction rope; see Figure 8 As shown, the mobile system includes a fixed frame 5 vertically arranged and fixed at the center position of a pair of ends of the rails 2, a mobile frame 6 arranged on a pair of the rails 2, and connected through the fixed frame 5. and the rolling bar 7 at the top of the mobile frame 6 and the support frame 8 connected to the front end of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com