Washing machine wastewater recycling system and method

A washing machine and waste water technology, applied in the field of washing machines, can solve the problems of cumbersome installation process of waste water reuse flushing toilet, toilet and washing machine cannot be commonly used together, and achieve the effect of simple structure, low cost and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

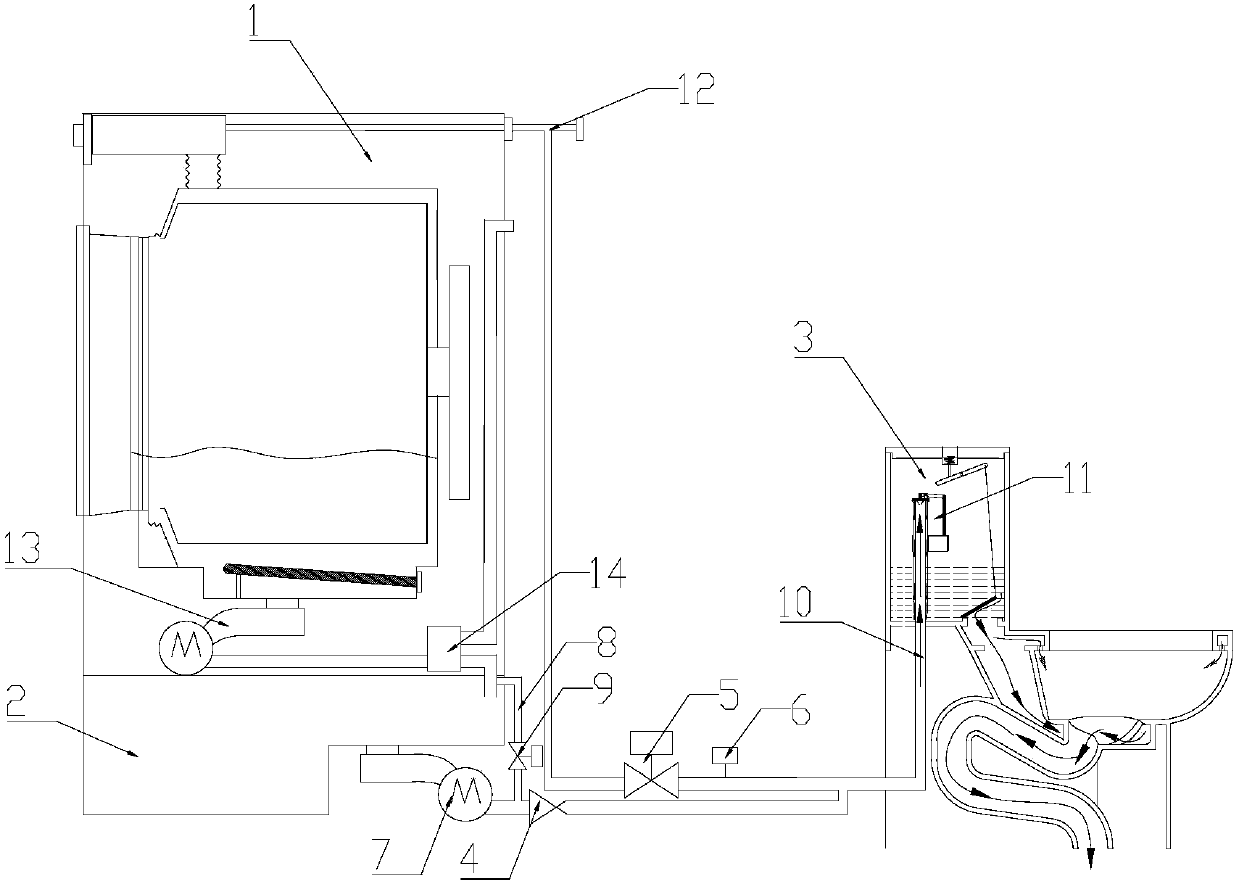

Embodiment 1

[0041] Such as figure 1As shown, the washing machine wastewater reuse system provided in this embodiment includes a water tank 2 for holding the waste water from the washing machine 1, the water tank 2 is connected to the toilet water chamber 3 through a first pipeline, and the toilet water chamber 3 Connect with the tap water pipe 12 through the second pipeline, and the direction from the water tank 2 to the toilet water chamber 3 on the first pipeline is provided with a drain pump and a first drain valve 4 in sequence, and the second pipeline is connected by a tap water pipe 12 The direction to the toilet water chamber 3 is provided with a second drain valve 5 and a sensor detection unit 6. According to the pipeline water flow information detected by the sensor detection unit 6, the opening / closing of the drain pump, the first drain valve 4 and the second drain valve 5 are controlled. closure.

[0042] Specifically, the first pipe and the second pipe communicate at a side c...

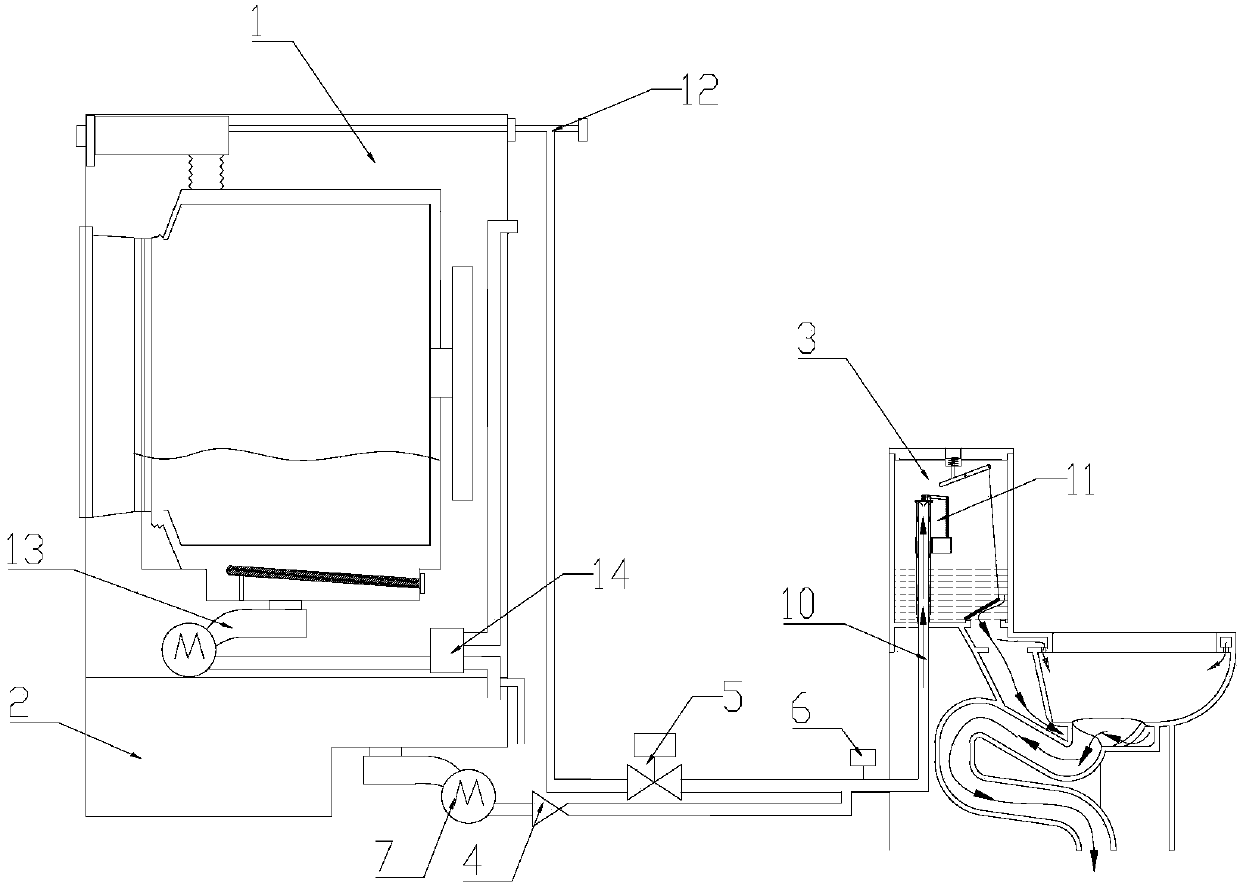

Embodiment 2

[0066] Such as figure 2 As shown, in the waste water reuse system for washing machines provided in this embodiment, the water tank 2 is provided with an exhaust port, the position of the exhaust port is higher than the position corresponding to the maximum water level of the water tank, and the distance between the drain pump and the first drain valve 4 is An exhaust pipe 8 is connected to the pipeline, and the other end of the exhaust pipe 8 communicates with the exhaust port;

[0067] Preferably, the diameter of the exhaust pipe 8 is smaller than the diameter of the first pipeline;

[0068] More preferably, the exhaust pipe 8 is provided with an exhaust valve 7, and the exhaust valve 7 is connected with a drainage pump.

[0069] Specifically, when the water tank 2 described in this embodiment is used for the first time or the user cleans the water tank 2 and uses it again, the gas in the first pipeline between the water tank 2 and the drainage pump will enter the drainage ...

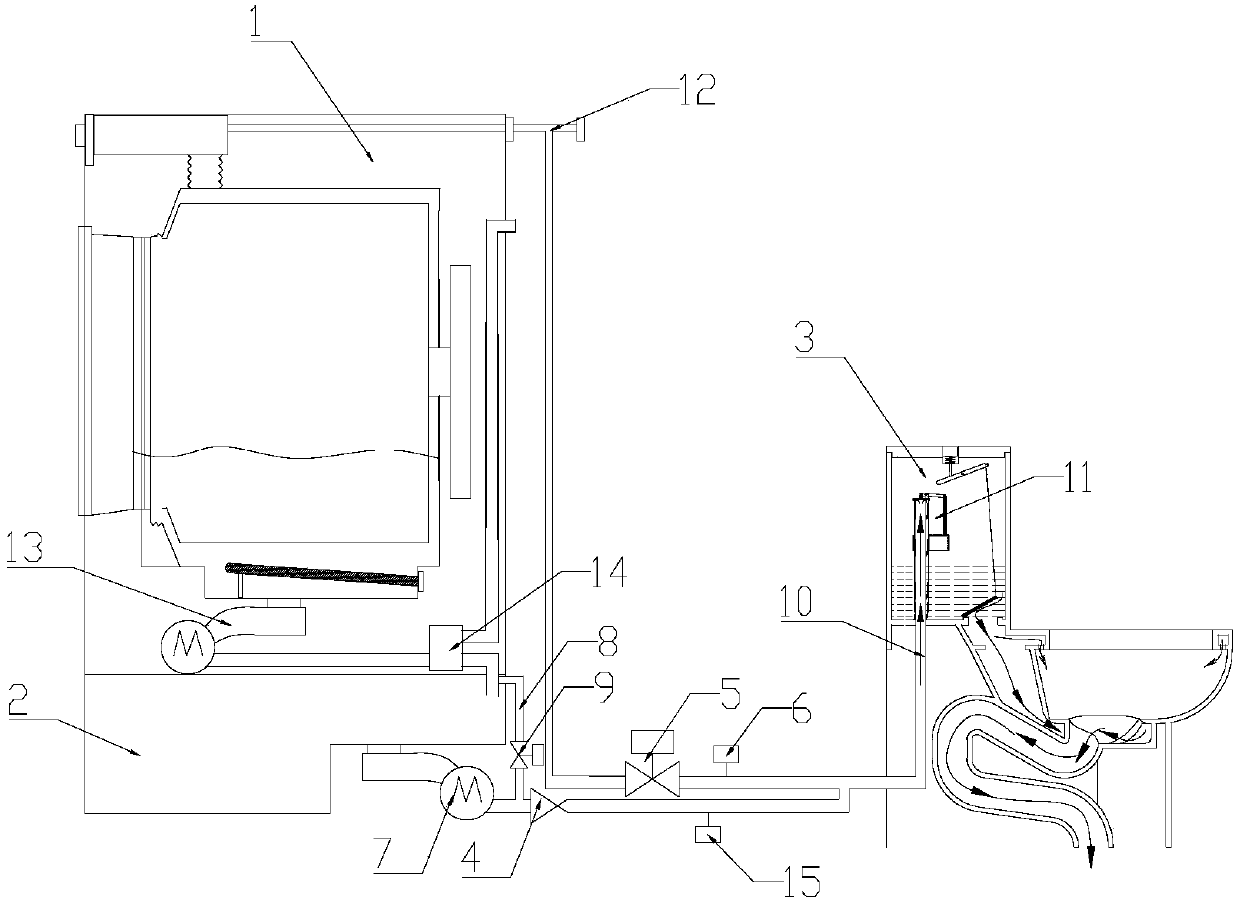

Embodiment 3

[0073] Such as image 3 As shown, the difference from the above embodiment is that in this embodiment, the first pipeline is provided with a drain pump, a first drain valve 4 and a second sensor detection unit 15 in sequence from the water tank 2 to the toilet water chamber 3 . Mainly by replacing the water level switch arranged in the water tank 2 with the second sensor detection unit 15 arranged on the first pipeline, it is realized whether the water tank 2 is used up, and the normal operation of the toilet is guaranteed.

[0074] In this embodiment, the second sensor detection unit 15 includes a flow sensor or a pressure sensor, wherein, when the second sensor detection unit 15 is a flow sensor, start the drain pump and the first drain valve 4 in the first pipeline Afterwards, the flow sensor detects the water flow value in the first pipeline, and when the detected flow value is lower than a certain set threshold value, then close the drainage pump and the first drainage v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com