Gel solution for 3D (Three Dimensional) printing platform

A 3D printing and gel liquid technology, applied in the field of gel liquid, can solve the problems of decreased printing accuracy, asynchronous motor, large space occupation, etc., and achieve the effect of reducing air resistance, reducing vibration amplitude, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

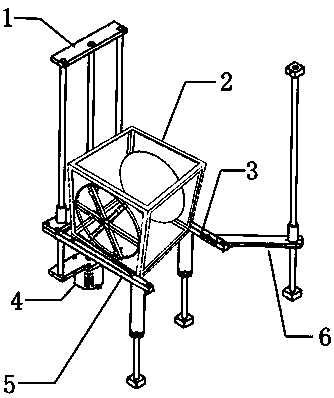

[0040] Such as figure 1 As shown, a 3D printing platform includes a print box 2 connected to a support. The print box 2 is a square cavity with an upper opening. The support includes a plurality of horizontal supports and vertical supports. The print box 2 is connected to the horizontal supports. The vertical support includes a support group 1, which is connected to the horizontal support. The bottom of the support group 1 is provided with a lifting support leg 4. The horizontal section of the support leg is rectangular, and the aspect ratio of the section is 1:0.3. The ratio of the length to the width of the bracket group is 0.4:1. The horizontal support includes a first support rod 3 and a second support rod 5. The length ratio of the first support rod and the second support rod is 1.7:1. The first support rod 3 and the second support rod 5 are connected to the bottom side of the printing box 2 The edges are connected. One end of the first rod 3 is movably connected with a ...

Embodiment 2

[0042] Printing includes the following steps,

[0043] Step 1: Adjust the height of the support feet and the support legs, adjust the angle of the rotating rod, and the height of the support rod, so that the print box 2 is in a horizontal and stable state, and the upper end of the support group 1 is connected to the print head;

[0044] Step 2: Turn on the temperature control device in the printing box 2 and adjust the printing box 2 to be within the constant temperature range of 17~24℃;

[0045] Step 3: The print head prints in the gel liquid, and rotates the wheel as needed to drive the paddle to wave the gel liquid, so that the object printed in the gel liquid rotates;

[0046] Step 4: After the printing is completed, the printed product is irradiated with ultraviolet light with a wavelength of 50~90nm and rinsed with water several times.

Embodiment 3

[0048] The gel liquid consists of 14 parts by mass of hexamethoxymethyl melamine, 23 parts of acrylate, 10 parts of methoxypolyethylene glycol acrylate, 27 parts of polyether polyol, 22 parts of pentanediol polyester polyol and 37 parts Composition of polycarboxylic acid. Among them, the polyether polyol is polyether triol; the polycarboxylic acid is a saturated pentacarboxylic acid; the pentanediol polyester polyol is a pentanediol polyester diol; the particle size of the gel liquid is 5 μm. The supporting force of the gel liquid is 2.1N / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com