Gold stamping machine alumite automatic recovering device

An automatic recycling and anodizing aluminum technology, applied in printing presses, rotary printing presses, transportation and packaging, etc., can solve the problems of waste of aluminum layer value, unfavorable base film recycling, impurity and harmful substances, etc., to improve production efficiency and achieve The effect of sorting and recycling and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

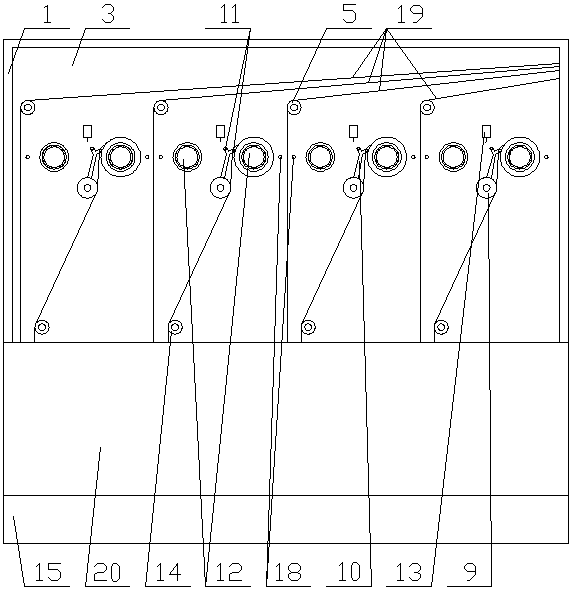

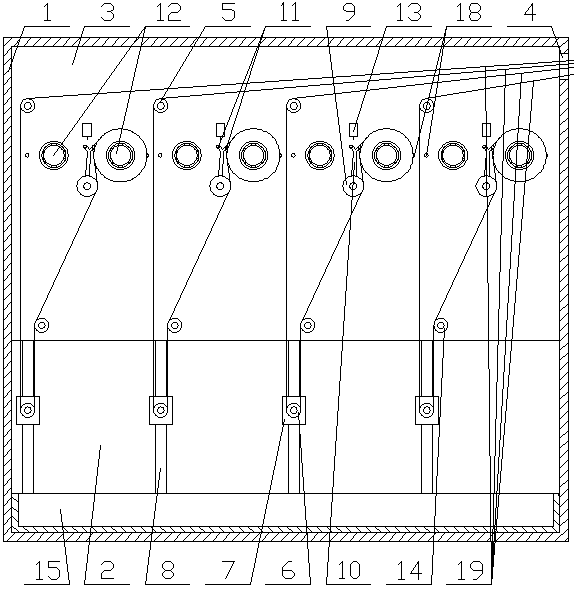

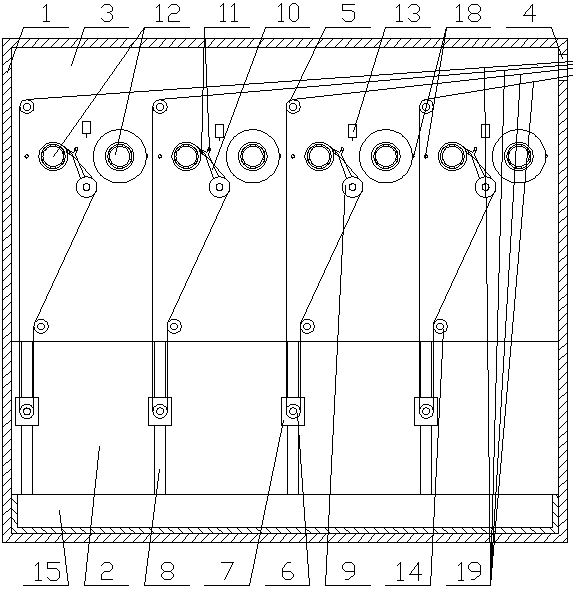

[0035] combine Figure 1~Figure 6It can be seen that the present invention includes a cabinet 1, the front end surface of the cabinet 1 is open, and the top inside the cabinet 1 is provided with an "L"-shaped partition 3 downwards, and the vertical wall of the "L"-shaped partition 3 The surface is parallel to the back plate 2 of the cabinet 1, and the side wall of the cabinet 1 is provided with a feed port 4 on the front side of the "L"-shaped partition 3, and a row of Turning rollers 5, on the front end surface of the separator 3, corresponding to each turning roller 5, an anodized aluminum winding device is also respectively provided, and the turning roller 5 is located on the side of the anodized aluminum winding device away from the feed port 4, The front end surface of the back plate 2 is located below the horizontal plate of the "L" shaped partition 3, and corresponding to each steering roller 5, a moving roller 6 that moves up and down is respectively provided; the anod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com