Glass intelligent distribution device

A conveying device and glass technology, which is applied to conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of a large number of manpower and materials, low efficiency and high cost, and achieve the effect of low operating cost and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention clearer, the device will be described in detail below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

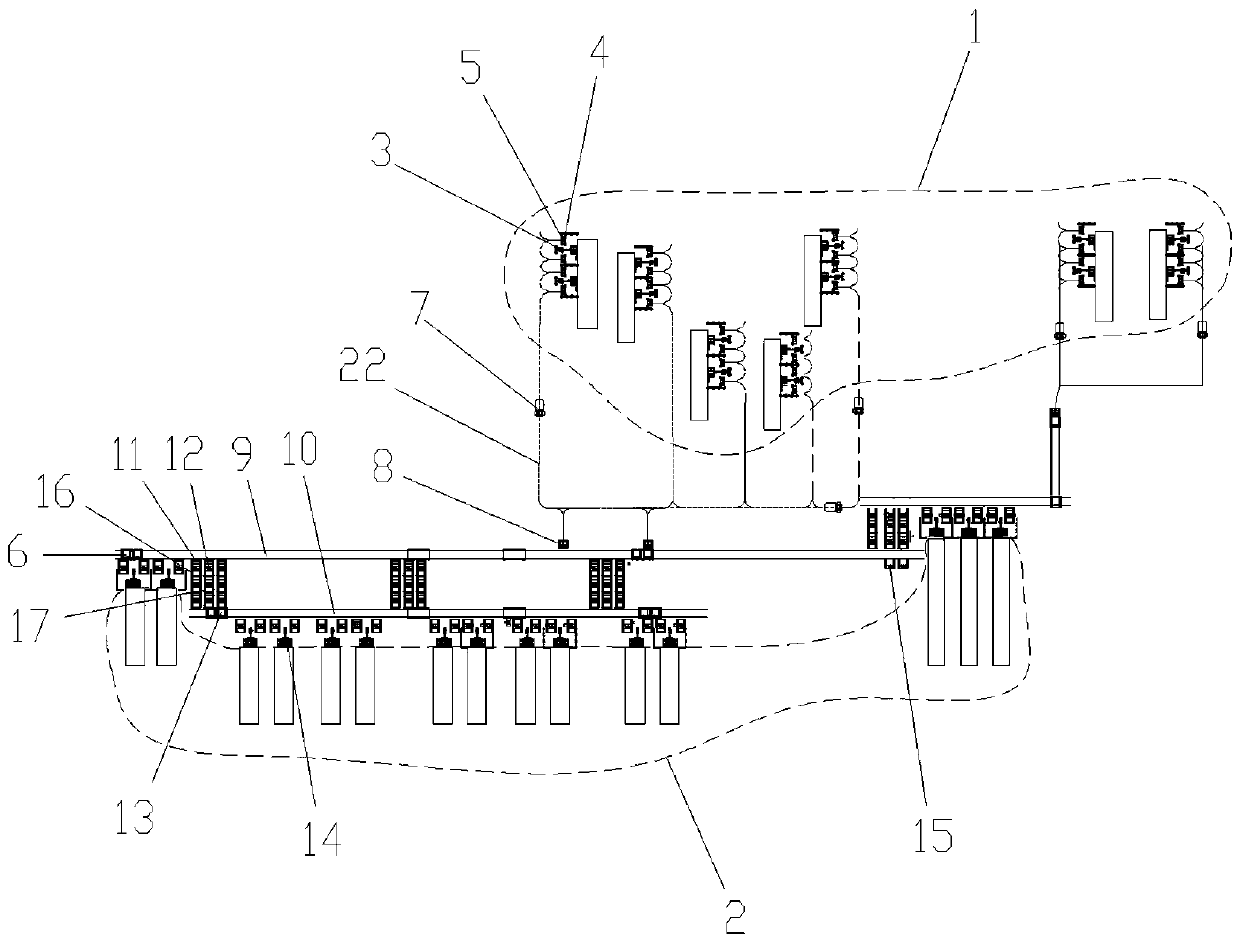

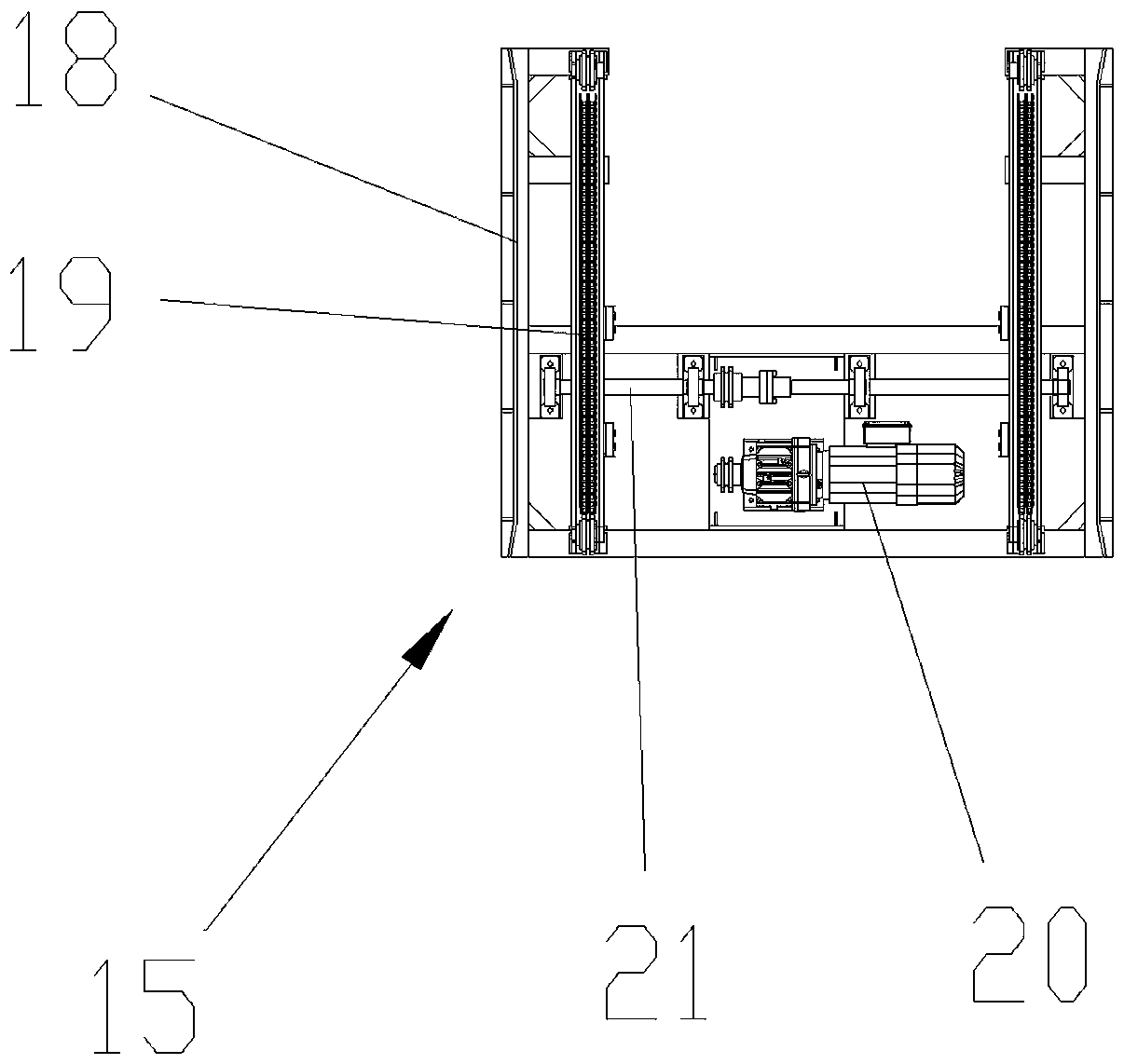

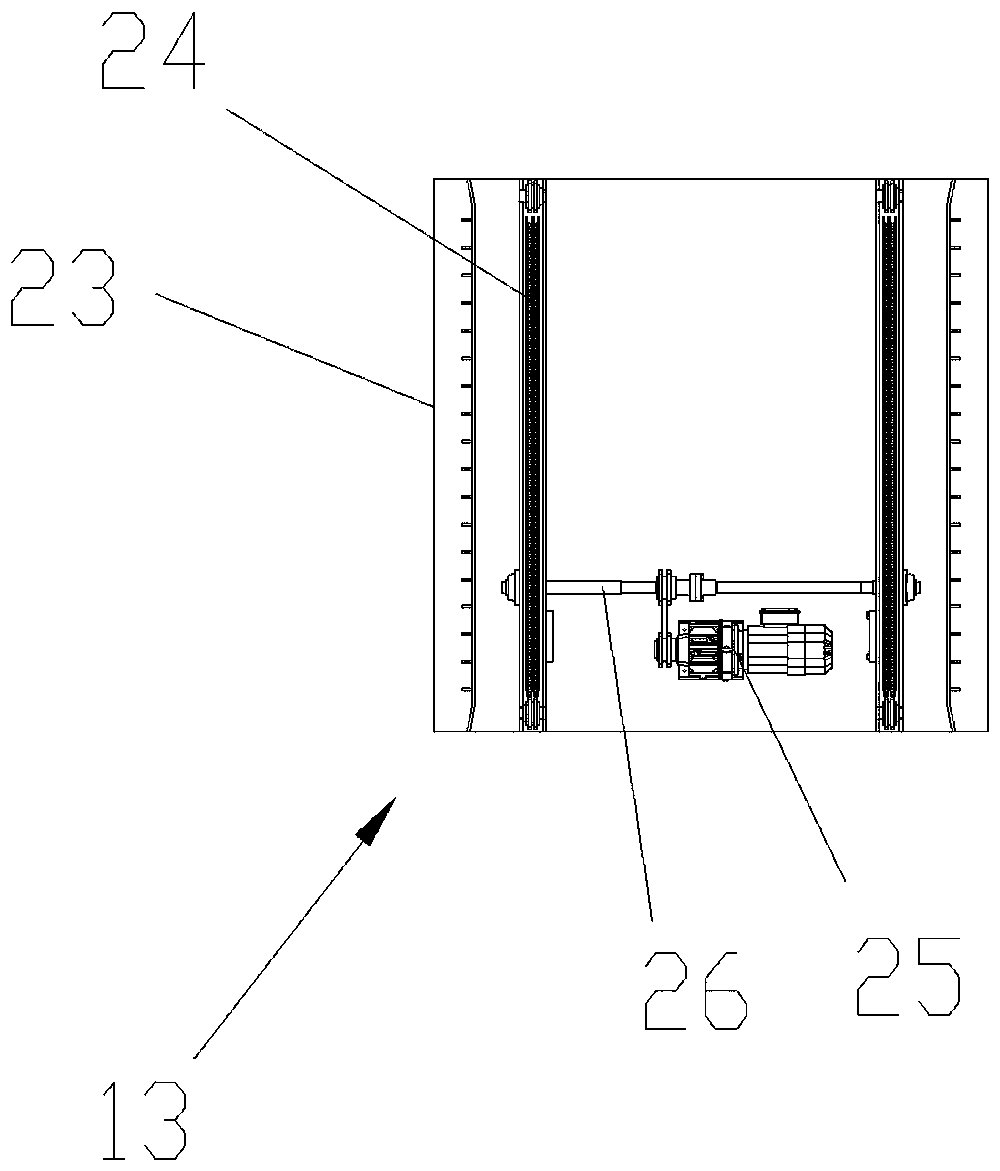

[0020] Such as figure 1 As shown, a glass intelligent dispensing device provided by the present invention includes a group of original sheet production lines 1 arranged on the upper side building and a group of deep processing production lines 2 arranged on the lower floor. On one side of each original sheet production line 1 At least one glass unloading robot 3 is provided, and a glass frame 4 is arranged on one side of each glass unloading robot 3, and a data tracking chip 5 is installed on each glass frame 4, and the data tracking chip 5 adopts an RFID chip. The RFID chip tracks, records, and allocates the running destination in real time through wireless communication. There is a set of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com