Fully-automatic production line applied to brake pad production

A fully automatic, production line technology, applied in the field of production lines, can solve problems such as increased employment costs, low processing efficiency, and potential safety hazards, and achieve the effects of reducing employment costs, improving work efficiency, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

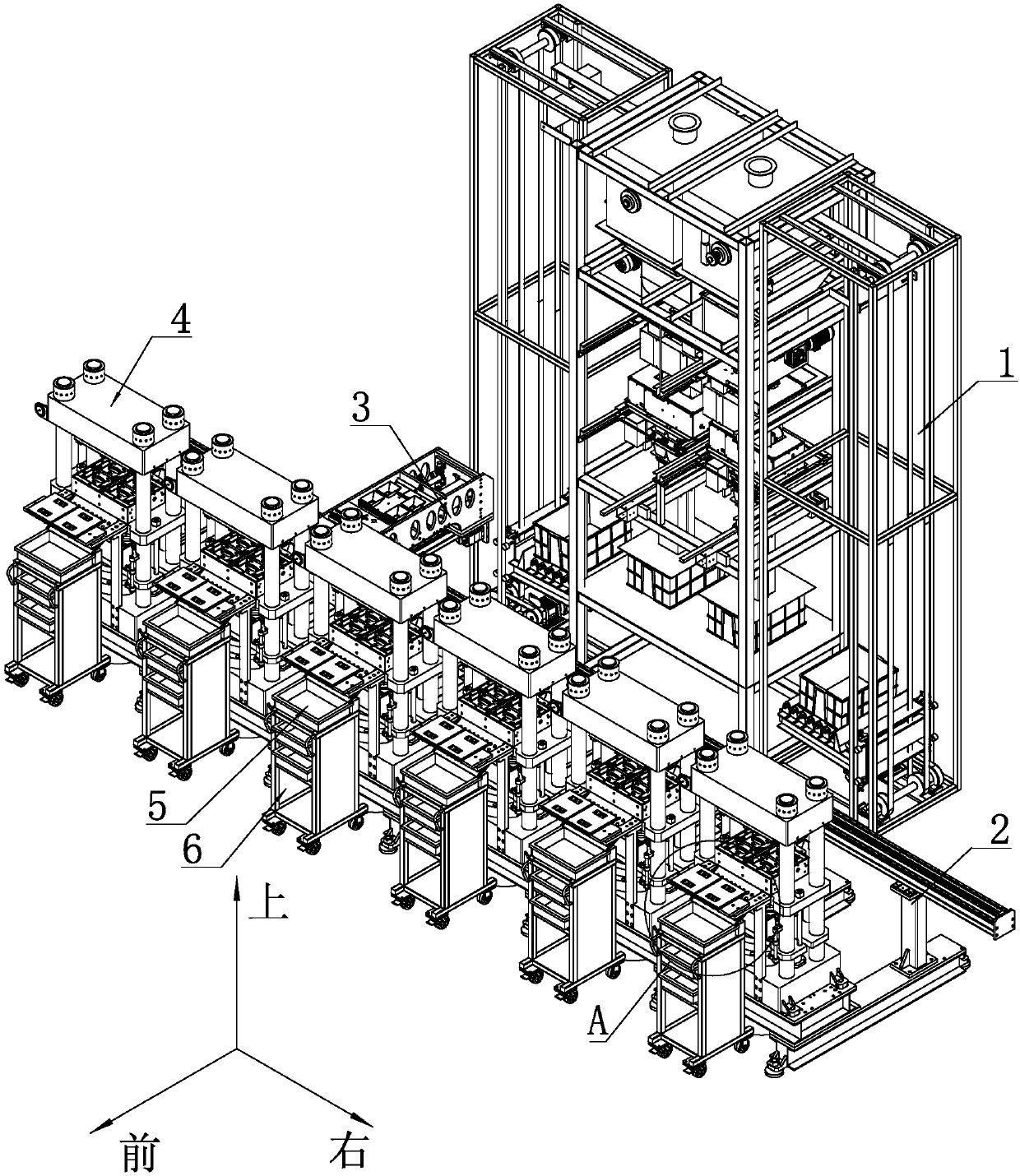

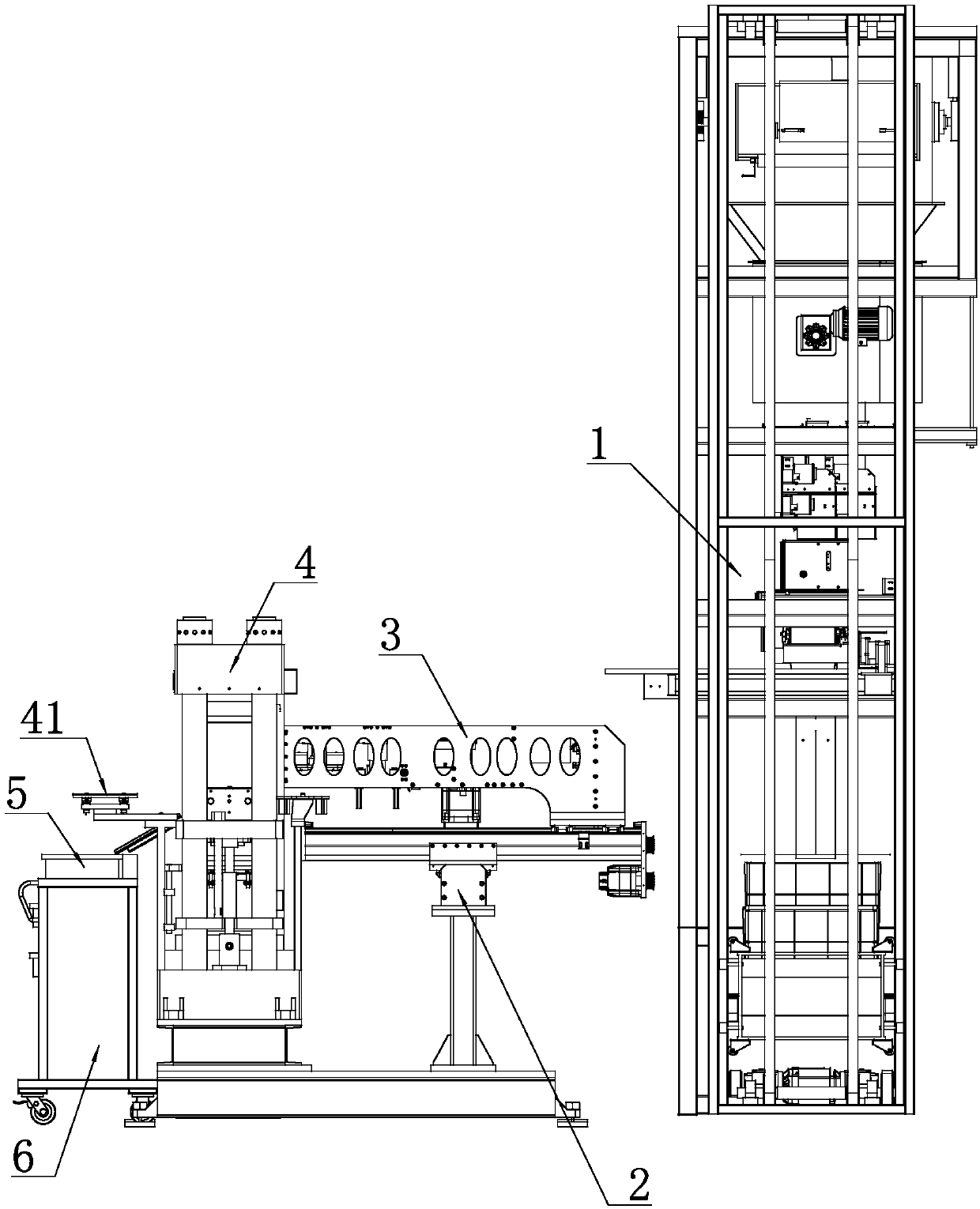

[0061] For the convenience of description, the coordinate system is defined as figure 1 As shown, and the left and right direction is the horizontal direction, the front and rear direction is the vertical direction, the corresponding horizontal direction is the row, and the vertical direction is the column.

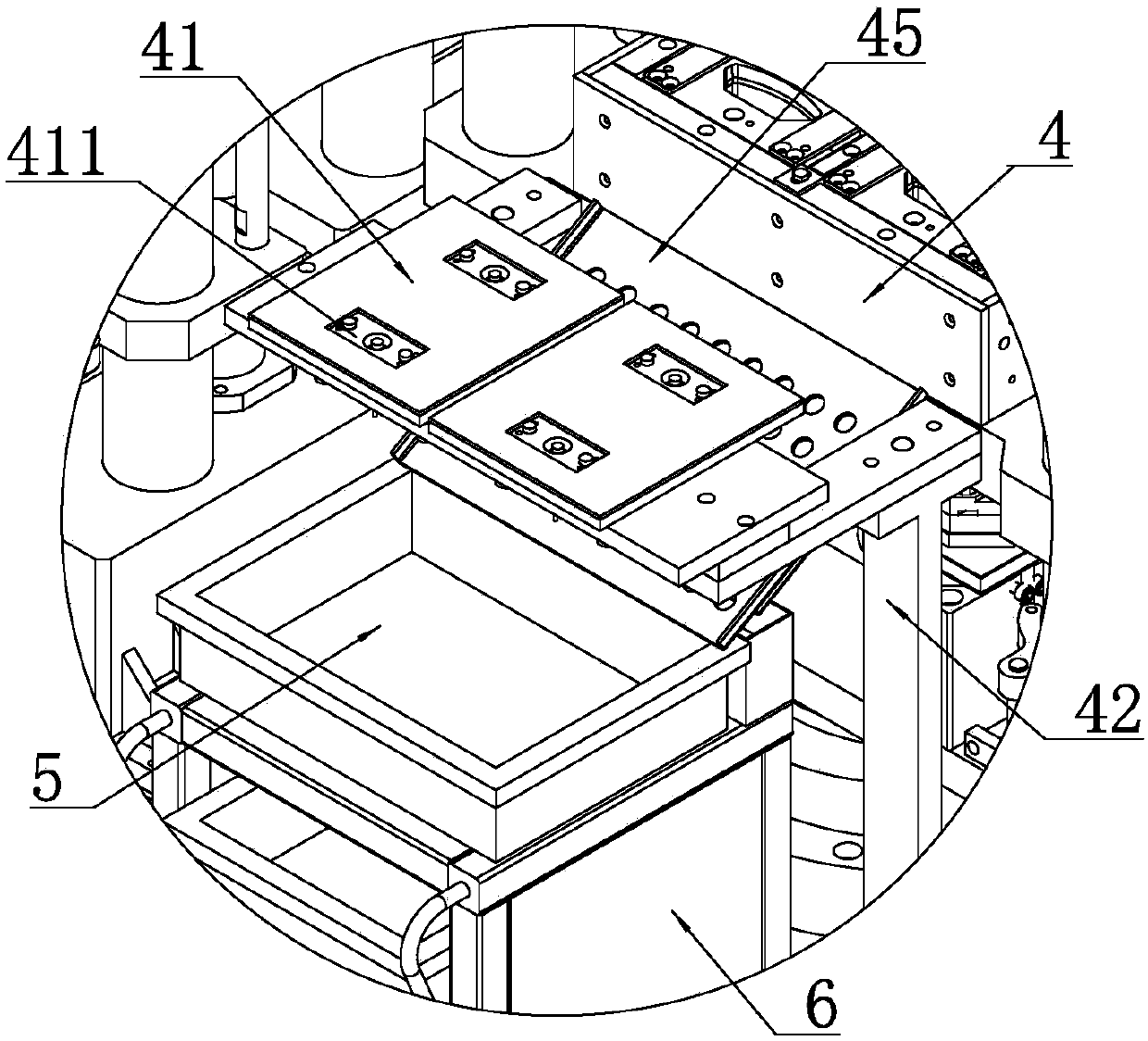

[0062] like figure 1 and figure 2 As shown, a fully automatic production line applied to the production of brake pads includes a weighing device 1, a feeding device and several hot presses 4 from front to back, and several hot presses 4 are horizontally arranged in a straight line. arrangement. The front side of each of the heat presses 4 is respectively provided with a receiving box 5 for holding finished brake pads.

[0063] Further, in order to facilitate the transfer of the processed brake pads, as a specific implementation, the receiving box 5 described in this embodiment is placed on a movable support 6 .

[0064] like image 3 As shown, the weighing device 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com