Vulcanizing machine for forming rubber damping seat

A technology of vulcanizing machine and rubber seat, applied in the field of vulcanizing machine, can solve the problems of air bubbles, misplacement of mold components and leakage of mold components, injection plugs, flash edges, etc., so as to improve the yield, improve production efficiency, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

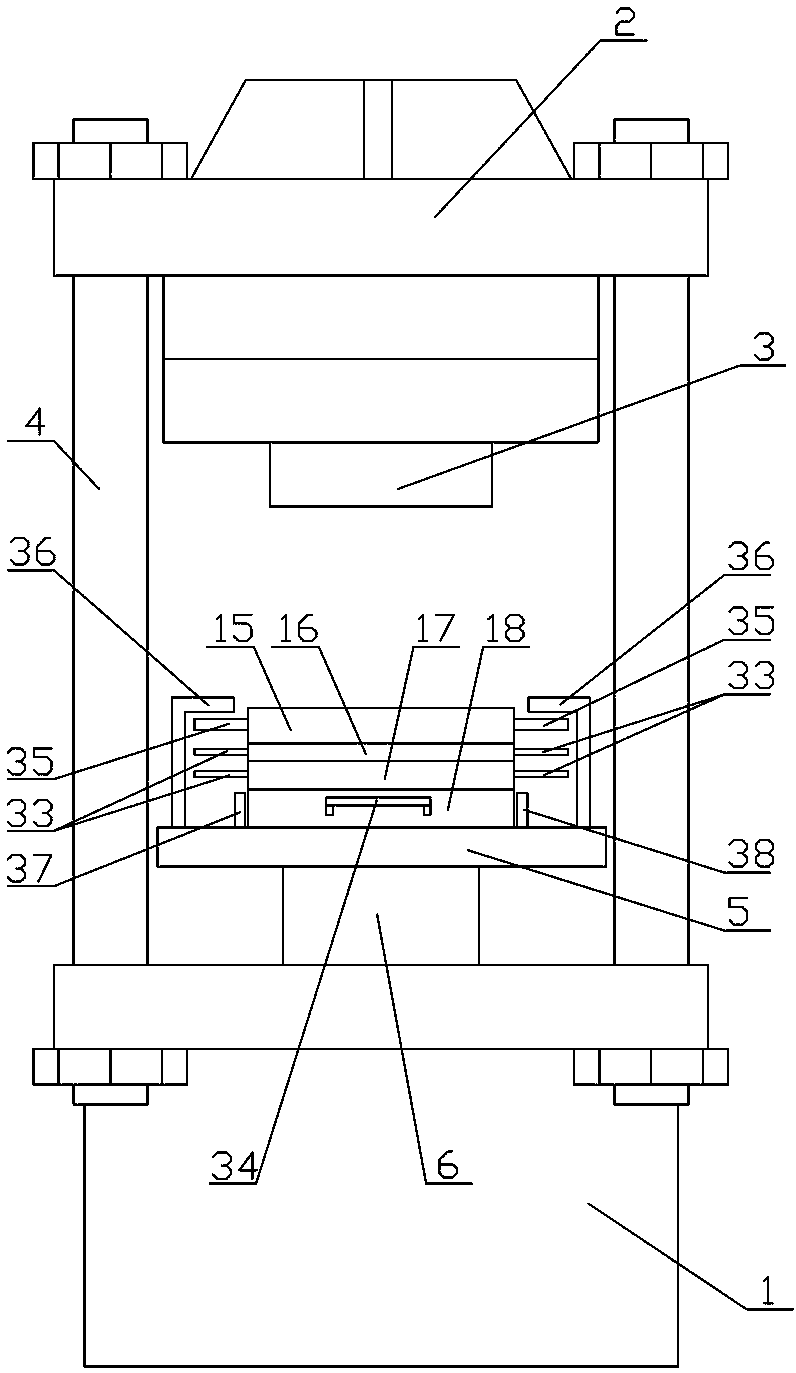

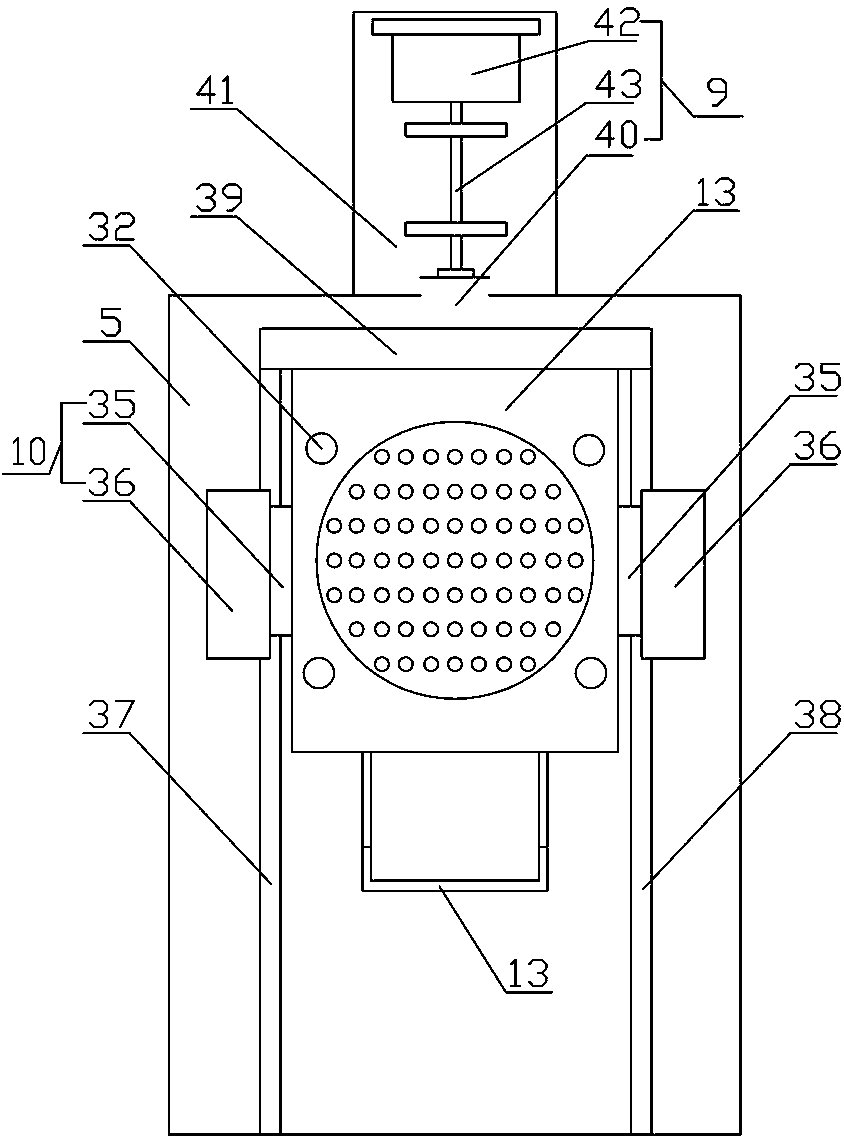

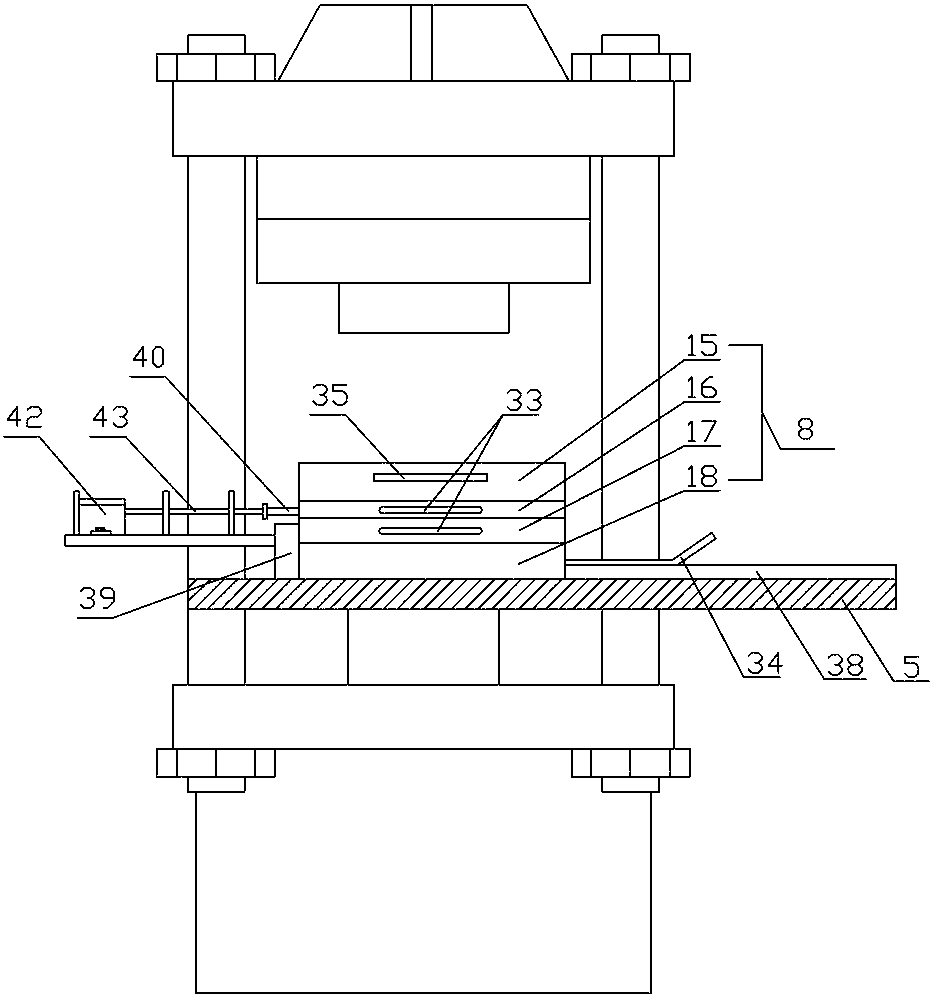

[0045] In this embodiment, a vulcanizer for forming a shock-absorbing rubber seat has a base 1 and a cover plate 2 located above the base 1. The bottom of the cover plate 2 is equipped with a plug 3 for heating the injection material. A plurality of guide posts 4 are connected between the base 1 and the cover plate 2, and a lifting platform 5 is movably fitted on the guide posts 4, and the bottom of the lifting platform 5 is connected with a hydraulic cylinder 6 installed on the base 1, so The drawer type activity on the table above the lift platform 5 is equipped with a mold assembly 8 that prevents the shock-absorbing rubber seat 7 from generating air bubbles, and the lift platform 5 is located at the bottom dead center of the drawer type activity of the mold assembly 8. Device 9, a blocking device 10 is installed on both sides of the lifting platform 5 to prevent the mold assembly 8 from sticking to the injection plug 3;

[0046] In this embodiment, the shock-absorbing rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com