Wood cutting machine capable of recycling chippings

A cutting machine, wood technology, used in wood processing appliances, bark area/chips/dust/waste removal, sawing equipment, etc., can solve the problem of not being able to recover chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

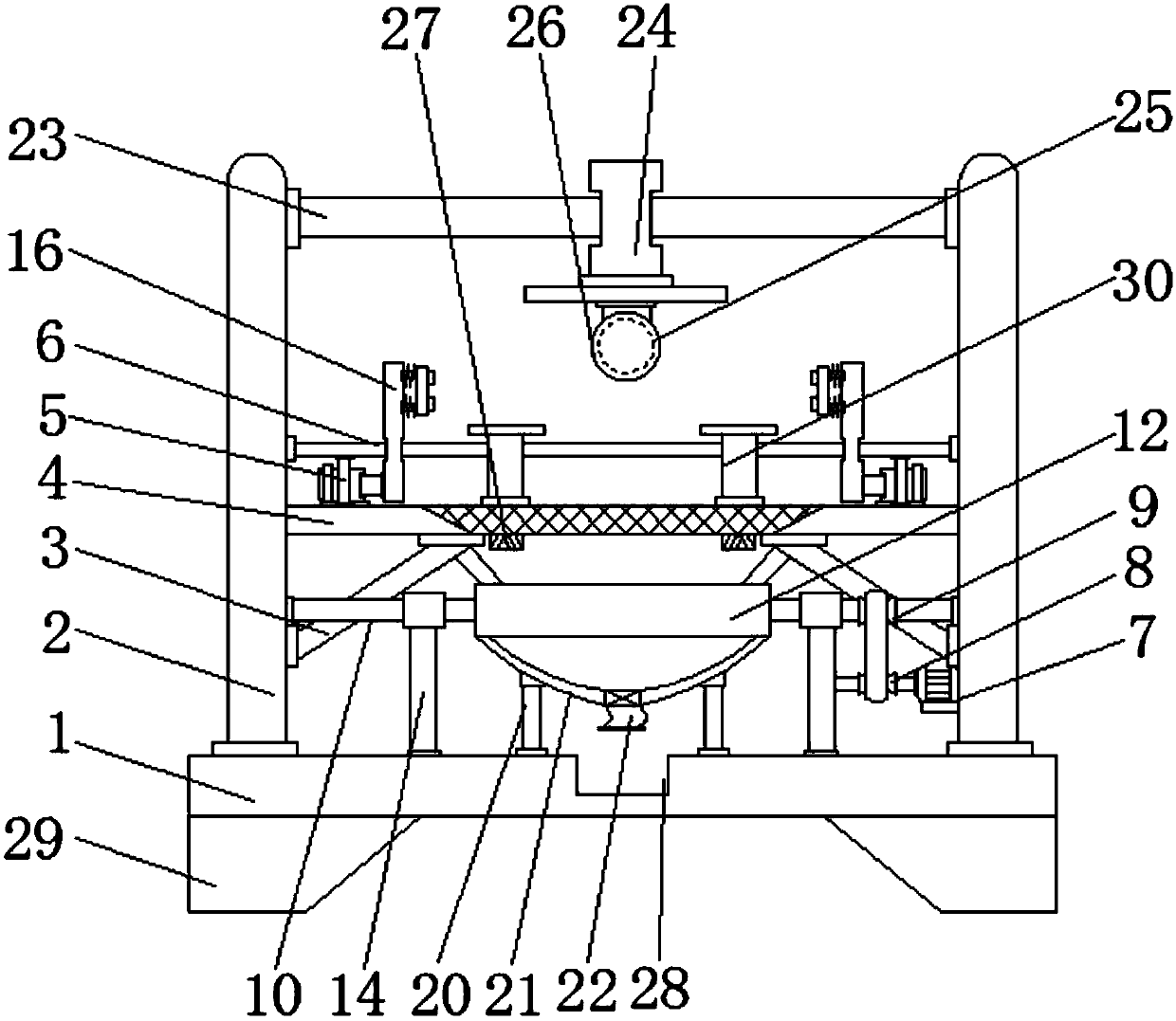

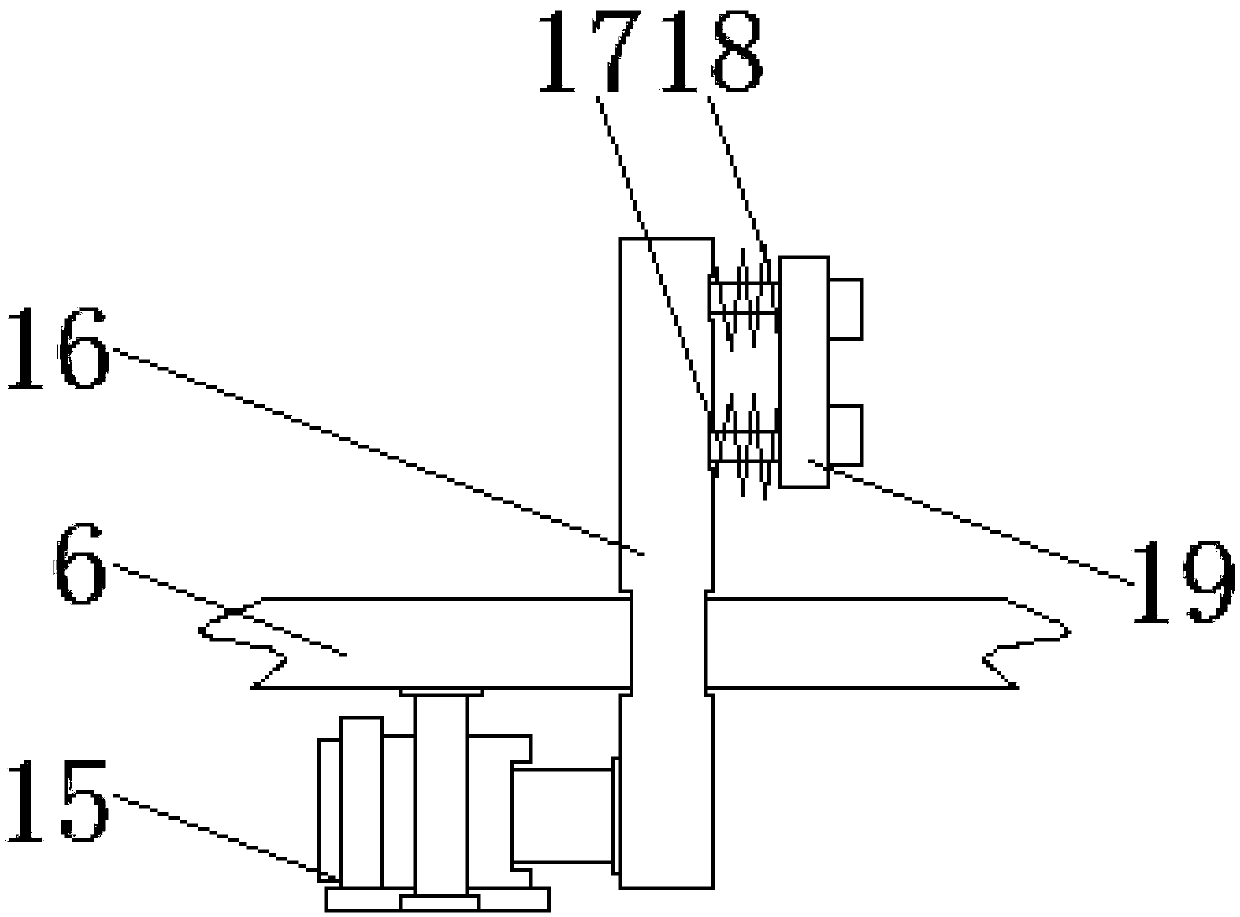

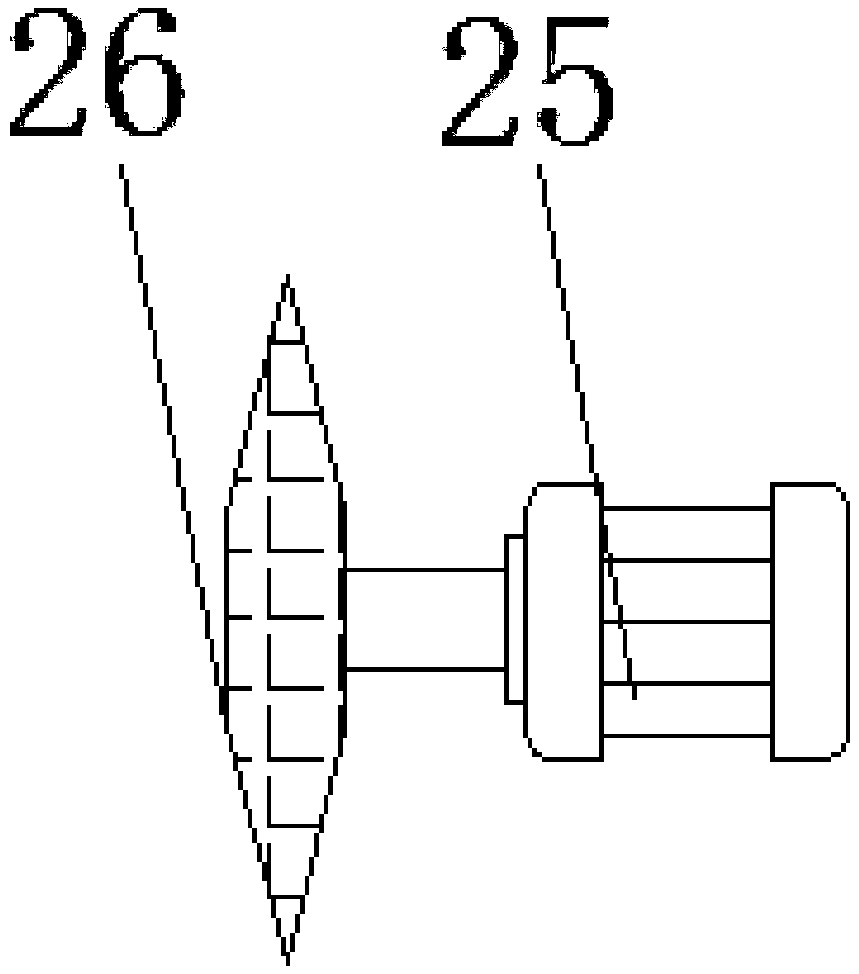

[0017] Such as Figure 1-Figure 4 As shown, a wood cutting machine with recyclable debris mainly includes a base plate 1, the top of the base plate 1 is provided with a receiving groove 28, and both sides of the bottom of the base plate 1 are fixedly connected with feet 29, and the top of the fixed plate 4 Both sides are fixedly connected with support platform 30, both sides of bottom plate 1 top are all fixedly connected with support plate 20, and the top of support plate 20 has material storage tank 21, and the bottom of material storage tank 21 runs through with discharge hopper 22, and discharge The inner wall of the hopper 22 is provided with a solenoid valve, both sides of the top of the bottom plate 1 are fixedly connected with a support plate 2, and the opposite sides of the support plate 2 are fixedly connected with a guide rail 23, and the surface of the guide rail 23 is slidably connected with a moving mechanism 24, The bottom of the moving mechanism 24 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com