Oil Film Bearing Bushing Babbitt Repair Tool and Method

A babbitt alloy and oil film bearing technology, applied in the field of rolls, can solve the problem that the fatigue layer is difficult to repair quickly, and achieve the effect of realizing rapid repair, avoiding cutting blind spots and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

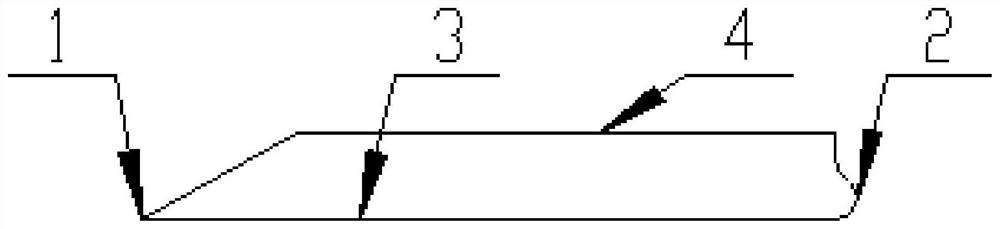

[0026] see figure 1 , This embodiment provides a babbitt repair tool for oil film bearing bushings, the tool includes a knife body, and the outer end of the knife body is provided with a knife back 4, a straight knife edge 3, a first edge and a second edge.

[0027] The knife back 4 is set opposite to the straight blade 3; the first side is set opposite to the second side. One end of the first side part joins with the knife back 4, and the other end of the first side part joins with the straight blade 3, and the first side part joins with the straight blade 3 to form a knife point 1, and the angle formed by the two sides of the knife point 1 is Acute angles (such as 15°, 60° or 85°). The foreign matter inlaid with the Babbitt alloy will cause scratches on the mirror surface of the oil film bearing bush, and cause a small area of Babbitt alloy to peel off. The foreign matter can be removed with the tip of the knife 1. One end of the second edge is connected to the back of t...

Embodiment 2

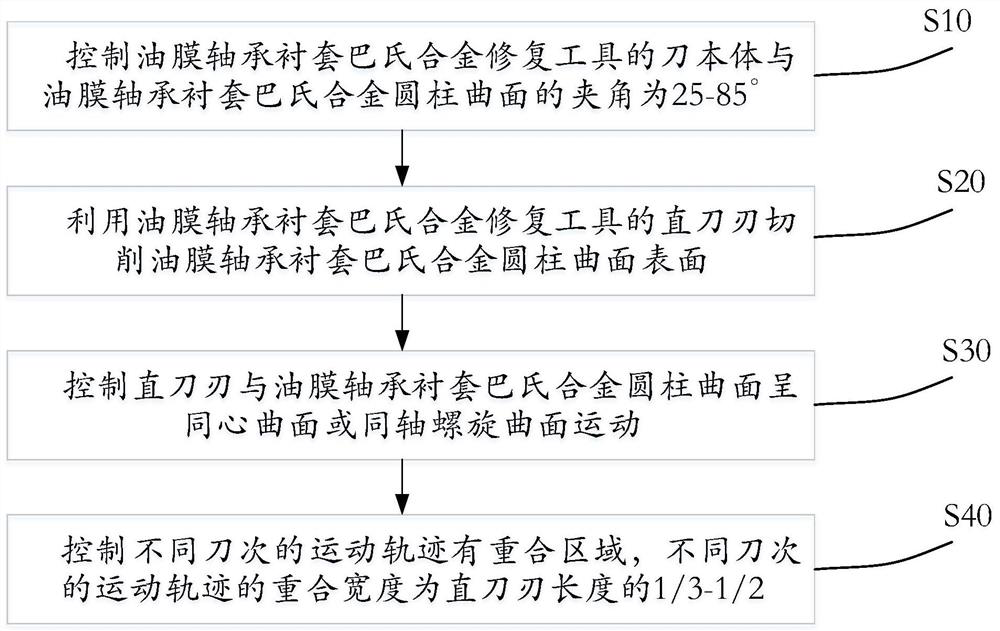

[0029] see figure 1 and figure 2 , the embodiment of the present invention provides a method for repairing an oil film bearing bush babbitt, the method comprising:

[0030] Step S10 , controlling the included angle between the tool body of the oil film bearing bush babbitt alloy repair tool and the oil film bearing bush babbitt alloy cylindrical surface to be 25-85° (such as 25°, 50° or 85°).

[0031] Step S20, using the straight blade 3 of the oil film bearing bush babbitt alloy repair tool to cut the surface of the oil film bearing bush babbitt metal cylinder curved surface.

[0032] Step S30, controlling the movement of the straight blade 3 and the Babbitt metal cylindrical surface of the oil film bearing bush to form a concentric surface or a coaxial helical surface; wherein, the coaxial helical surface movement includes forward coaxial helical surface movement or anti-coaxial helical surface movement.

[0033] Step S40 , controlling that the motion trajectories of diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com