Astaxanthin-containing piglet feed additive as well as preparation method and application thereof

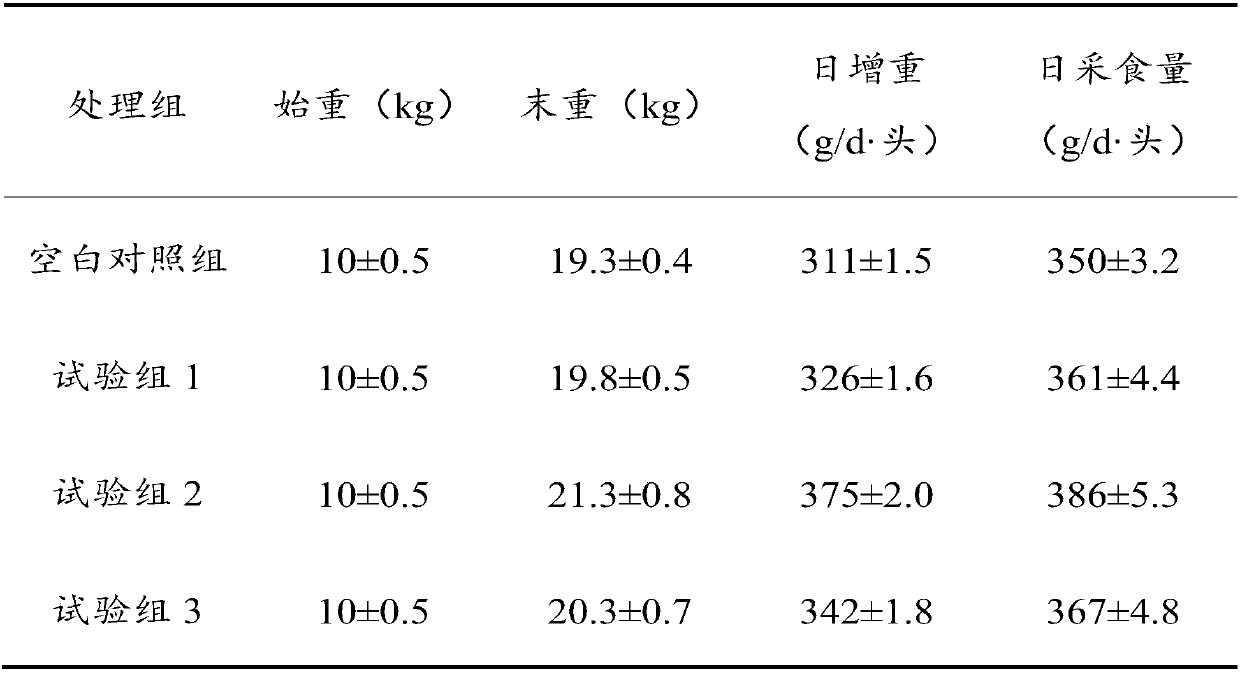

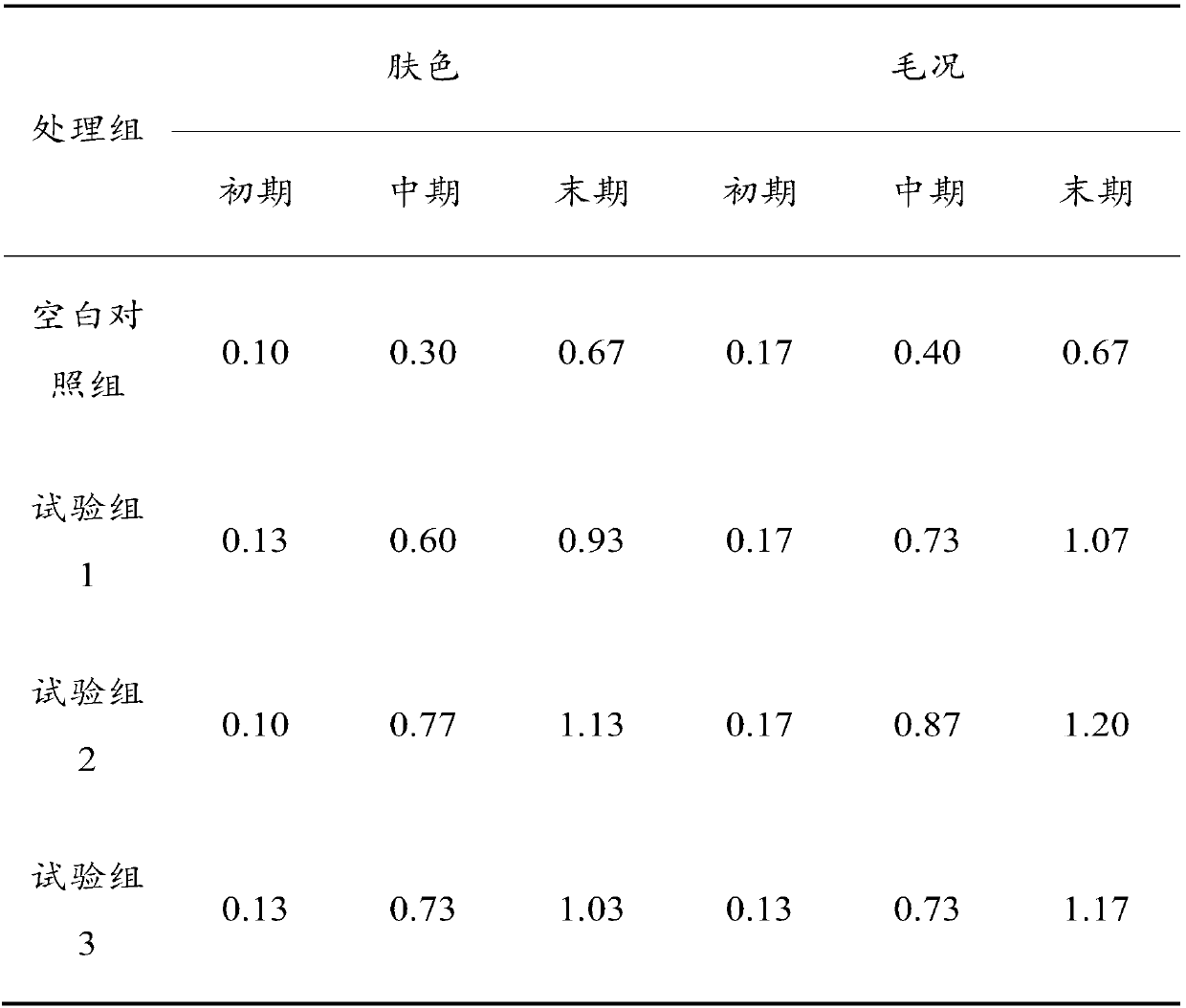

A piglet feed and additive technology, applied in the fields of application, animal feed, animal feed, etc., can solve the problems of complex astaxanthin process, low absorption efficiency, and inability to transform, so as to improve piglet skin color and hair quality, increase absorption rate, Improve daily weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the above-mentioned astaxanthin-containing piglet feed additive may, for example, include the following steps: enzymatically hydrolyze the algae powder with a compound enzyme to obtain an enzymatic hydrolysis solution, and then dry it. Wherein, the composite enzyme includes cellulase and protease.

[0027] Specifically, mix the algae powder with deionized water at a material-to-liquid ratio of 1g: 3-5mL, adjust the pH of the mixture to the optimum pH of the compound enzyme, heat to 30-40°C, and then add the compound enzyme for enzymolysis .

[0028] As an option, the above-mentioned algae powder is preferably Haematococcus pluvialis powder, and the astaxanthin extracted from the algae powder has a better antioxidant effect.

[0029] Because the astaxanthin contained in the algae powder cells is difficult to be effectively absorbed by piglets, the embodiment of the present invention adds a compound enzyme during the preparation process to break...

Embodiment 1

[0046] Mix Haematococcus pluvialis powder with deionized water according to the ratio of material to liquid: 1g: 3mL, adjust the pH value of the mixture to 6, and heat to 40°C.

[0047] A compound enzyme containing cellulase and neutral protease at a weight ratio of 1:3 was added, the dosage of the compound enzyme was 3% of the weight of the algae powder, and the enzymolysis time was 6 hours at 40°C. In the process of enzymolysis, a compound small peptide chelating salt with a chelation rate of 70% is added. The amount of the compound small peptide chelating salt is 0.05% of the weight of the algae powder. The compound small peptide chelating salt contains small Peptide Chelated Zinc and Small Peptide Chelated Iron.

[0048] After enzymatic hydrolysis, the enzyme was inactivated at 90°C for 10 minutes to obtain an enzymatic hydrolysis solution.

[0049] The enzymolysis solution is concentrated to 30% of the mass of the original enzymolysis solution under the condition of 50° ...

Embodiment 2

[0052] Mix Haematococcus pluvialis powder with deionized water according to the material-to-liquid ratio of 1g:4mL, adjust the pH value of the mixture to 7, and heat to 35°C.

[0053] Add a compound enzyme containing cellulase and neutral protease at a weight ratio of 1:4, the amount of the compound enzyme is 2% of the weight of the algae powder, and the enzymolysis time is 7 hours at 35°C. In the enzymolysis process, a compound small peptide chelating salt with a chelation rate of 75% is added. The amount of the compound small peptide chelating salt is 0.03% of the weight of the algae powder. The compound small peptide chelating salt contains small Peptide Chelated Zinc and Small Peptide Chelated Iron.

[0054] After enzymatic hydrolysis, the enzyme was inactivated at 90°C for 15 minutes to obtain an enzymatic hydrolysis solution.

[0055] The enzymolysis solution is concentrated to 40% of the mass of the original enzymolysis solution under the condition of 50 DEG C, and vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com