Preparation method of prunus armeniaca kernel oil microcapsules

A technology of almond oil and big flat apricot, applied in the production/processing of edible oil/fat, edible oil/fat composition, etc., can solve the problems of inconvenient use and storage, easy oxidation of oil and short storage period, etc. Solve the effects of easy oxidation, short time and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of almond oil microcapsules comprises the following steps:

[0030] Step 1, adding 1g of almond powder to each 12ml of petroleum ether, and extracting the almond oil from the almond oil by ultrasonic-assisted extraction, the ultrasonic frequency is 60Hz, the ultrasonic power is 270W, and the extraction time is 25min;

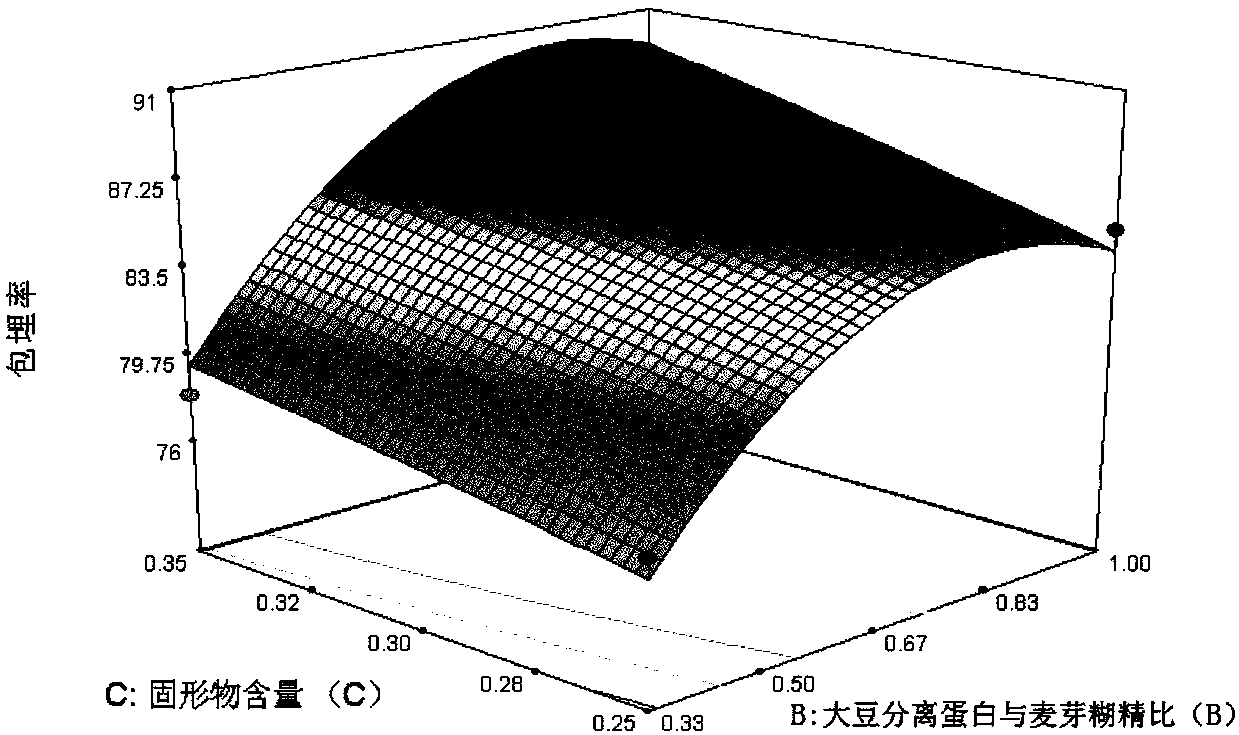

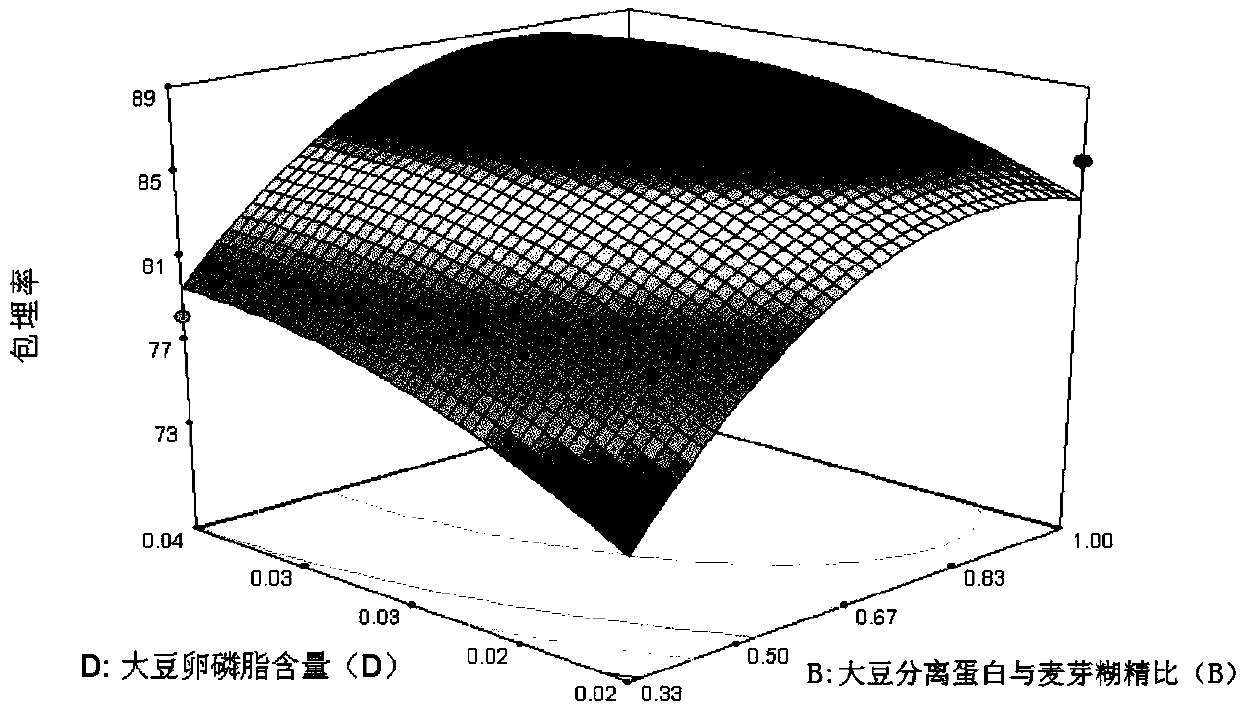

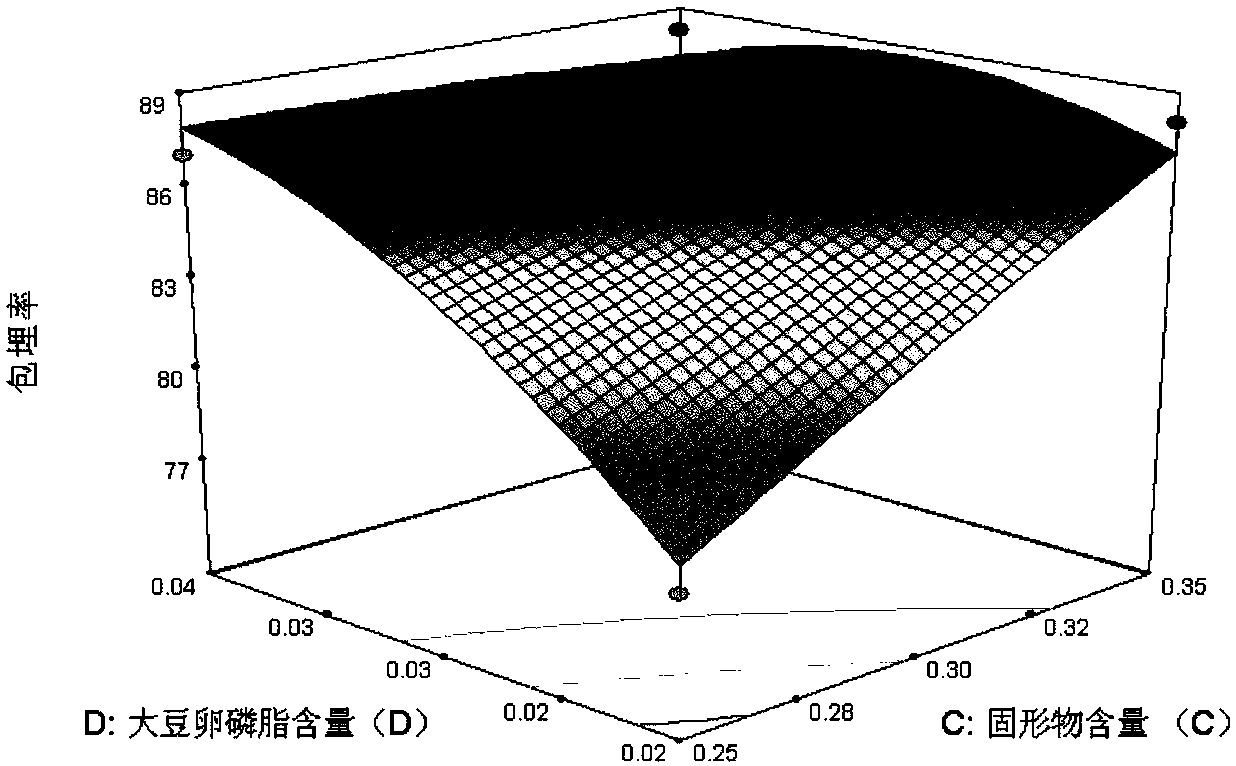

[0031] Step 201, mixing soybean protein isolate and maltodextrin as a solid, dissolving in distilled water at 48°C to 52°C, and stirring for 30 minutes at the same time, keeping the resulting mixed solution at 48°C to 52°C, wherein the soybean protein isolate and malt The ratio of dextrin mass is 0.3;

[0032] Step 202, slowly add soybean lecithin and almond oil obtained in step 1 to the mixed solution obtained in step 201, and perform ultrasonic emulsification. The parameters of ultrasonic emulsification are power 390W, frequency 50Hz, interval 1s, working for 3s, and emulsification time 5min, to obtain emulsification Liquid, wher...

Embodiment 1

[0035] Example 1, according to the different content of the core material relative to the solid content, the content of other components is determined unchanged, the solid content is 30%, the ratio of soybean protein isolate to maltodextrin is 1:2, and the content of soybean lecithin is 3%. , the content of almond oil is 20%, 25%, 30%, 35%, 40%, 45%, respectively, when the core material accounts for 30%, 35%, and 40% of the solid content, the embedding of the wall material to the core material When the core material accounts for 35% of the solid content, the embedding rate reaches a peak of 80.34%.

Embodiment 2

[0036] In Example 2, the core material is set to account for 20% of the solid content, and the solid content is 30%. The ratios of soybean protein isolate and maltodextrin are 1:3, 1:2, 1:1, and 2:1, respectively. It was carried out at 3:1, and the embedding rate of the final microcapsules was detected. The ratio of soybean protein isolate to maltodextrin was 1:2 and the embedding rate reached a peak value of 75.88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com