Semiconductor templates and fabrication methods

A semiconductor and template technology, applied in the field of semiconductor template production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

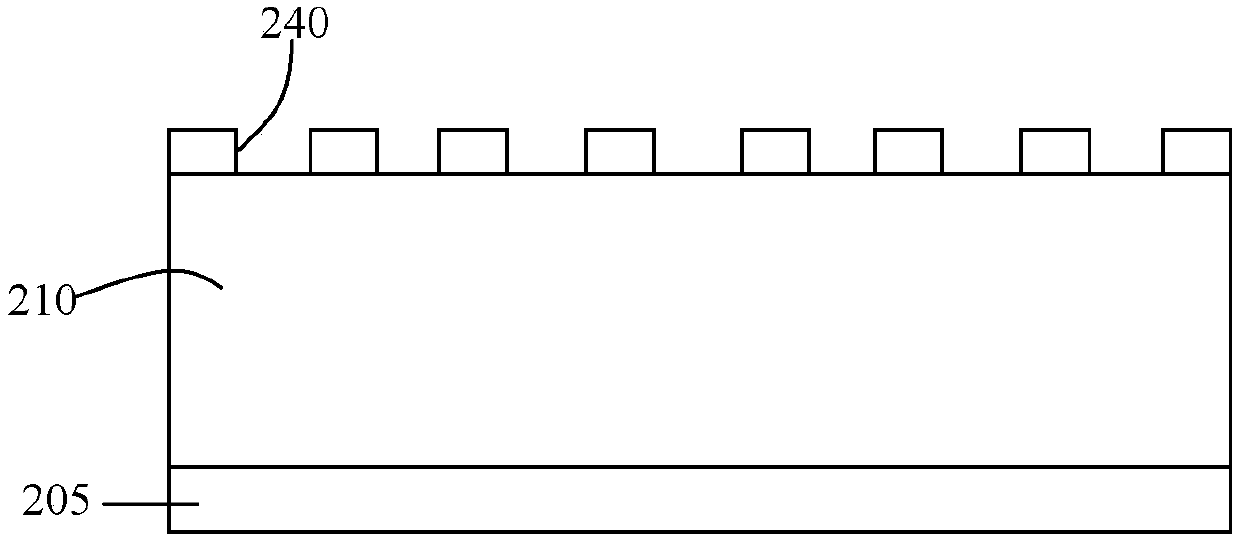

[0049] see Figure 1a , the first step in fabricating a semiconductor template is to provide a suitable semiconductor wafer 201 . Wafer 201 is conventional and consists of a substrate 205, in this case comprising a layer of sapphire, on top of which is a semiconductor layer 210 formed of gallium nitride (GaN). Other materials can be used. For example, the substrate can be silicon (flat or patterned) or silicon carbide (flat or patterned). The semiconductor may be another suitable material, for example another group III nitride such as indium gallium nitride (InGaN) or aluminum gallium nitride (AlGaN) or indium nitride (InN) or aluminum nitride (AlN). Semiconductor wafers are semipolar. Specifically, in this embodiment, the GaN is oriented such that its top surface parallel to the plane of the substrate (referred to herein as the horizontal plane) is in the (11-22) plane. A buffer layer or a nucleation layer, such as high-temperature AlN or thin low-temperature GaN or thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com